Steel slag-metakaolin compound gel material and preparation method thereof

A composite cementitious material, metakaolin technology, applied in climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as underutilization and large emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

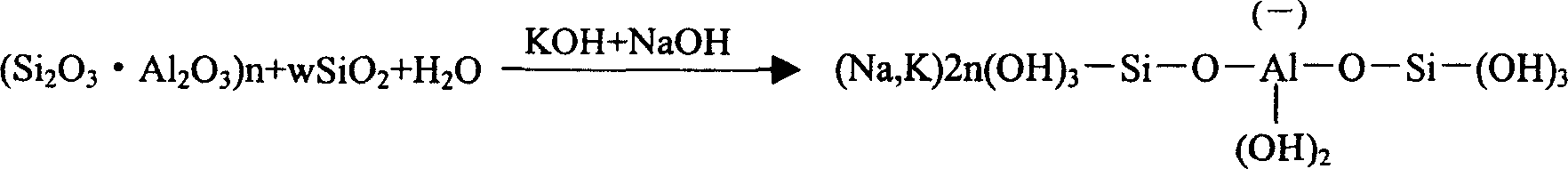

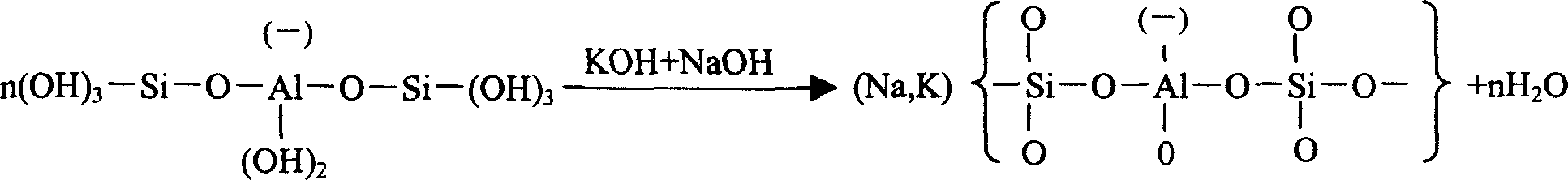

[0021] One, the preparation method of steel slag-metakaolin composite cementitious material:

[0022] The preparation method of steel slag-metakaolin composite cementitious material comprises the following steps: 1). Firstly, the steel slag with alkalinity>1.2 is ground until the specific surface area is 400-650m 2 / kg to form fine steel slag powder; take coal series kaolin and forge it at 650-800°C to a fineness of 500-700m 2 / kg of metakaolin; pulverize sodium fluoride to form powder; then carry out mechanical mixing in the ratio of steel slag: metakaolin: sodium fluoride in the ratio of = 1: (0.1-9): (0.022-0.2) Make it uniform, then seal, pack, and seal to obtain steel slag-metakaolin-sodium fluoride powder; 2). Slowly add NaOH solid into the sodium silicate solution to dissolve to obtain a modulus of 1.0-2.0 and Baume degree Water glass solution at 33-44°; according to steel slag: water glass solution: Na 2 SO 4 The mass ratio is=1: (0.66-8): (0.033-0.3) choose water g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com