Method for making core with aeration ossification

A gas hardening, core sand technology, applied in the direction of cores, manufacturing tools, casting and molding equipment, etc., can solve the problems of alloy casting application limitations, large loss of sand core strength, affecting popularization and application, etc., to achieve low cost of core making, manufacturing Short cycle and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 1200g of standard sand for casting binder and put it into ST195 cement mortar mixer, add 30g of ZS2.50 casting water glass and 3g of glyceryl triacetate in accordance with JB / T8835 standard, stir for 60s to produce sand, and mix the above Put the sand mixture into the sand shooting cylinder of Z861 core shooting machine, use Z861 core shooting machine to shoot the standard "8" shape sample under the pressure of 0.4 ~ 0.6Mpa, remove the sand shooting cylinder, seal the sand shooting port, and turn on the FXS gas Generator solenoid valve, so that the mixed gas containing 60% methyl formate, 40% ethanol, and air volume accounts for 30% of the hardening mixture is passed into the core box for 10 to 30 seconds, the hardening gas source is closed, and the hot air blowing valve is opened for 3 seconds. , into 50 ~ 100 ℃ hot air for 60 ~ 80s, after the end of blowing, stop the air supply, open the core box, take out the "8" shape sample. Use the SWY hydraulic strength tes...

Embodiment 2

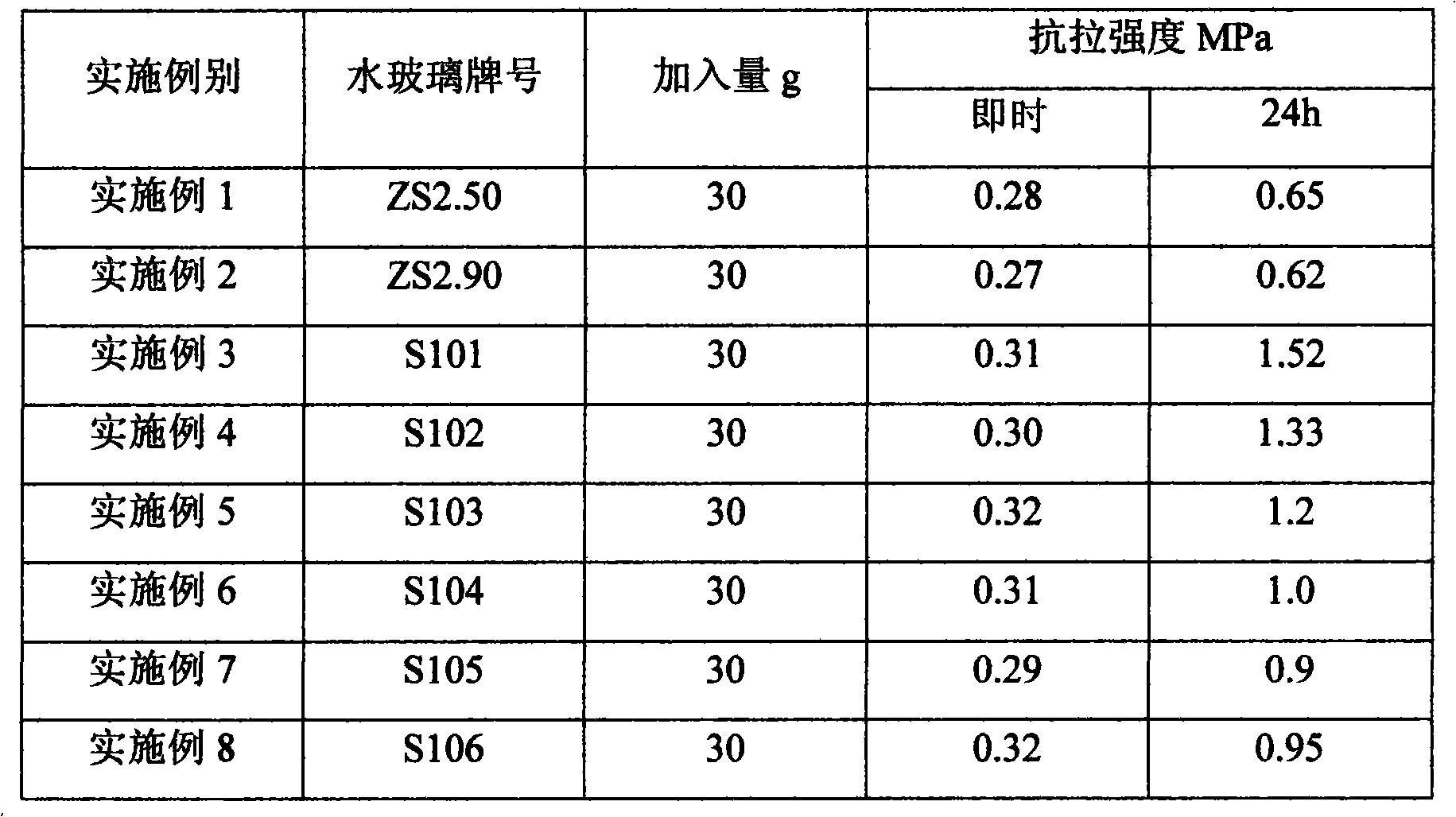

[0036] Embodiment 2, Embodiment 3, Embodiment 4, Embodiment 5, Embodiment 6, Embodiment 7, and Embodiment 8 respectively take standards JB / T8835, ZS2.90 casting water glass and standards Q / HYT.01 New water glass S101, S102, S103, S104, S105, S106 for casting, other conditions are the same as in Example 1, and the obtained detection strengths are listed in Table 1.

[0037] Table 1 Effect of different water glasses on mechanical properties

[0038]

Embodiment 9

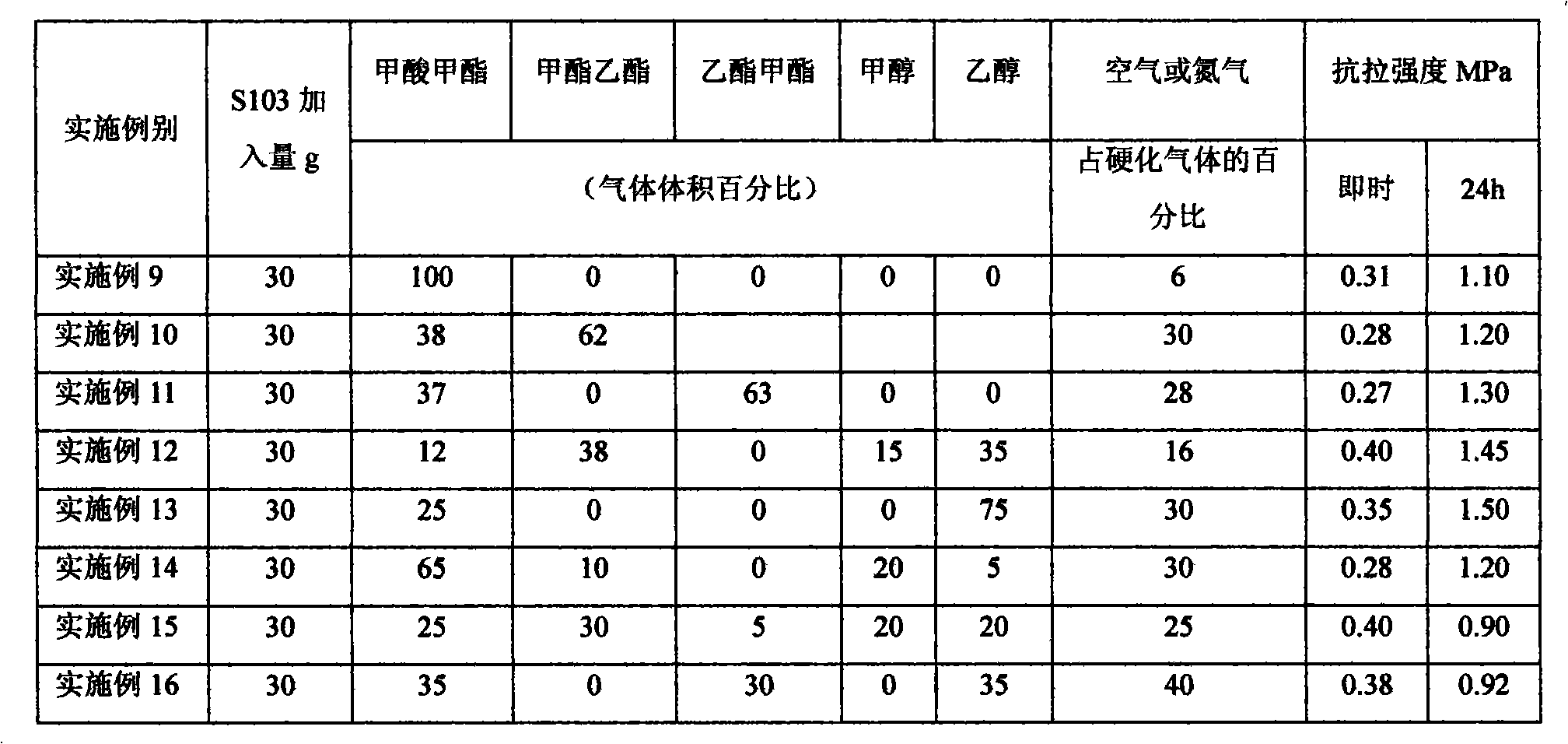

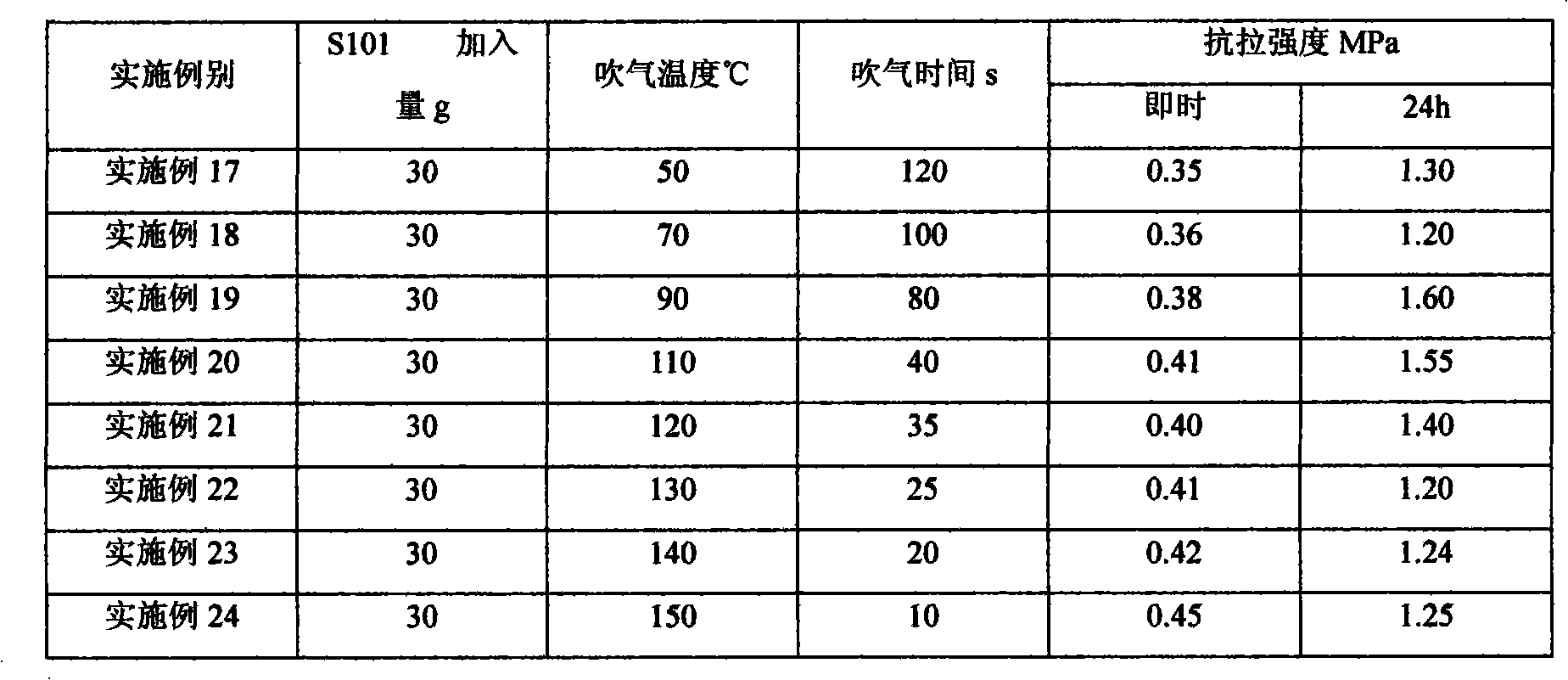

[0039] Embodiment 9, embodiment 10, embodiment 11, embodiment 12, embodiment 13, embodiment 14, embodiment 15, embodiment 16, embodiment 17, embodiment 18, implementation procedure is identical with embodiment 1, adopts water The glass is all S103, the hardening gas carrier is nitrogen, and nitrogen accounts for the volume percentage of hardening gas. The implementation conditions are listed in Table 2, and the conditions not listed are the same as in Example 1. The hardened samples are measured immediately and 24h tensile strength respectively, and List the results in Table 2.

[0040] Table 2 Effect of different air-hard gases on mechanical properties

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com