Normal-pressure rapid preparation method for hydrophobic silica aerogel powder

A hydrophobic silica and aerogel technology, applied in the polymer field, can solve problems such as unfavorable large-scale production and complex preparation process, and achieve the effects of uniform size and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

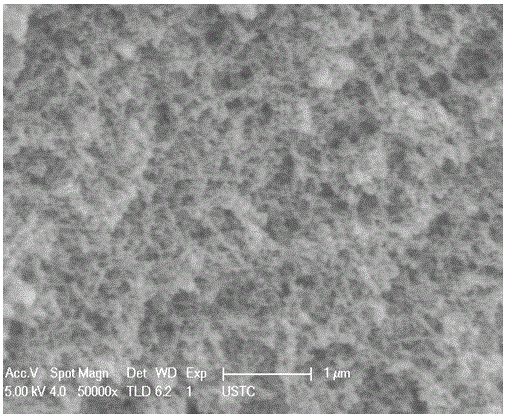

Image

Examples

Embodiment 1

[0021] Mix and stir deionized water and water glass (3.55 mold, mass fraction 32.16%) at a volume ratio of 1:2; take 15ml of diluted water glass and add it to 3ml of 5M hydrochloric acid, and stir when adding to make it evenly mixed. The pH of the solution was controlled to be 2 to obtain solution A. Take 50ml of n-hexane, add 0.2ml of Span 80 into it, stir at 400r / min for 1min, and obtain solution B. Add solution A to solution B, mix well, then add 1ml of 5M ammonia water to it, adjust the pH of the solution to 5.5, keep stirring at high speed during this step, add ammonia water and stir for 2 minutes, the stirring speed is 300r / min, Form uniform gel small particles. The gel particles were aged in a water bath at 45 °C for 1 h. Pour out and recover the remaining n-hexane and Span 80 in the gel, then add 25ml of trimethylchlorosilane, 12ml of ethanol and 50ml of n-hexane to the gel particles for exchange and modification in a water bath at 45°C. After 6 hours, add 10ml of w...

Embodiment 2

[0023] Mix and stir deionized water and water glass (3.55 mold, mass fraction 32.16%) at a volume ratio of 1:4; take 15ml of diluted water glass and add it to 3ml of 5M hydrochloric acid, and stir when adding to make it evenly mixed. The pH of the solution was controlled to be 2 to obtain solution A. Take 50ml of n-hexane, add 0.2ml of Span 80 into it, stir at 400r / min for 1min, and obtain solution B. Add solution A to solution B, mix well, then add 1ml of 5M ammonia water to it, adjust the pH of the solution to 6, keep stirring at high speed during this step, add the alkaline catalyst and stir for 2 minutes to form a uniform gel small particles. The gel was aged in a water bath at 45 °C for 1 h. Pour out and recover the remaining n-hexane and Span 80 in the gel, then add 25ml of trimethylchlorosilane, 12ml of ethanol and 50ml of n-hexane to the gel particles for exchange and modification in a water bath at 45°C. After 6 hours, add 10ml of water into the container and stir ...

Embodiment 3

[0025] Mix and stir deionized water and water glass (3.55 mold, mass fraction 32.16%) at a volume ratio of 1:3; take 30ml of diluted water glass and add it to 6ml of 5M hydrochloric acid, and stir when adding to make it evenly mixed. The pH of the solution was controlled to be 2 to obtain solution A. Take 150ml of n-hexane, add 0.5ml of Span 80 into it, stir at 600r / min for 1min, and obtain solution B. Add solution A to solution B, mix well, then add 2ml of 5M ammonia water to it, adjust the pH of the solution to 6, keep stirring at high speed during this step, add the alkaline catalyst and stir for 2 minutes to form a uniform gel small particles. The gel was aged in a water bath at 45 °C for 1 h. Pour out and recycle the remaining n-hexane and Span 80 in the gel for next use. Afterwards, 55ml of hexamethyldisilazane, 24ml of ethanol and 100ml of n-hexane were added to the gel particles, and exchange and modification were carried out in a water bath at 45°C. After 6 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com