Method for preparing southern dry land acidic soil conditioner

A technology of acidic soil and conditioner, which is applied in the field of soil agricultural chemistry, can solve the problems that have not yet been seen in the patent literature and reports of the preparation method of acidic soil conditioner in the southern dry land, destroy the permeability of plant plasma membrane, and soil compaction, etc., to increase the diversity of microorganisms performance, reduce water leakage and fertilizer leakage, and prevent soil compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

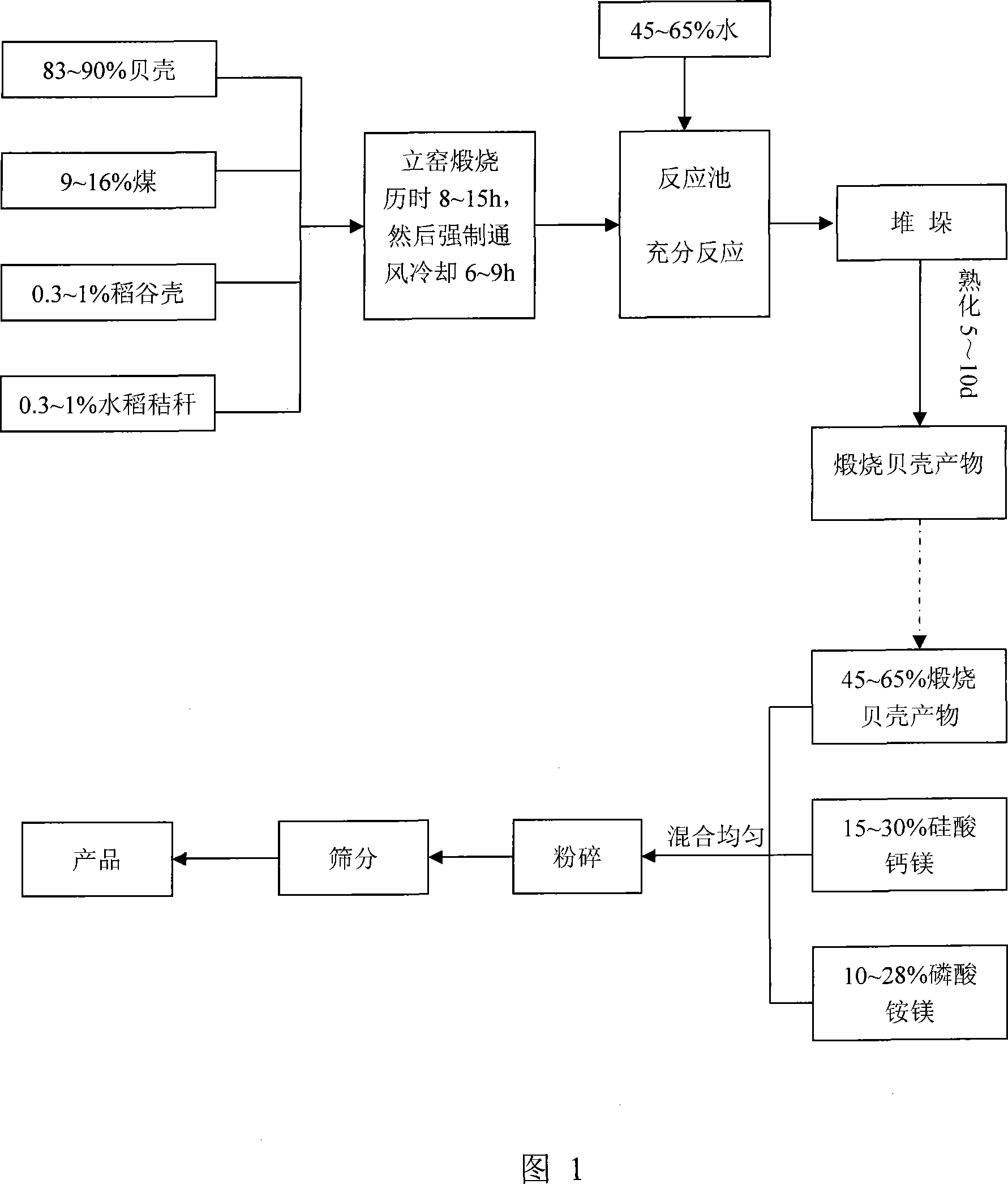

[0021] (1) Mix 83% shells, 16% coal, 0.5% rice stalks and 0.5% rice husks and put them into the shaft kiln for high-temperature calcination, and perform forced ventilation if necessary. The temperature is controlled at 1100°C, calcined for 8 hours, and the shaft kiln is operated with semi-open flame operation. After the calcination, it was forced to ventilate and cooled to room temperature (20-30° C.) for 9 hours, and finally the calcined product was obtained.

[0022] (2) Transfer the calcined product into the reaction tank, add 45% water of the mass of the calcined product to fully react, stack and mature the reaction product for 5 days, and finally obtain the calcined shell product.

[0023] (3) Fully mix 45% calcined shell products, 30% calcium magnesium silicate and 25% ammonium magnesium phosphate to obtain a mixed material.

[0024] (4) Pulverize the mixed material, sieve and sieve (φ1mm), and finally mix to obtain the product of the present invention, the southern upl...

Embodiment 2

[0026] (1) Mix 89% shells, 9% coal, 1% rice straw and 1% rice husk and put them into the vertical kiln for high-temperature calcination, and perform forced ventilation if necessary. The temperature is controlled at 800°C, calcined for 15 hours, and the vertical kiln operation adopts the semi-open flame operation method. After the calcination, the forced ventilation was cooled to room temperature for 6 hours, and finally the calcined product was obtained.

[0027] (2) Transfer the calcined product into the reaction tank, add 52% water of the mass of the calcined product to fully react, stack and mature the reaction product for 8 days, and finally obtain the calcined shell product.

[0028] (3) Fully mix 62% calcined shell products, 15% calcium magnesium silicate and 23% ammonium magnesium phosphate to obtain a mixed material.

[0029] (4) Pulverize the mixed material, sieve and sieve (φ1mm), and finally mix to obtain the product of the present invention, the southern upland ac...

Embodiment 3

[0031] (1) Mix 90% shells, 9.4% coal, 0.3% rice stalks and 0.3% rice husks and put them into the vertical kiln for high-temperature calcination, and perform forced ventilation if necessary. The temperature is controlled at 900°C, calcined for 13 hours, and the vertical kiln operation adopts the semi-open flame operation method. After the calcination, it was forced to ventilate and cooled to room temperature for 7 hours, and finally the calcined product was obtained.

[0032] (2) Transfer the calcined product into the reaction tank, add 65% water of the mass of the calcined product to fully react, stack and mature the reaction product for 10 days, and finally obtain the calcined shell product.

[0033] (3) Fully mix 57% calcined shell products, 15% calcium magnesium silicate and 28% ammonium magnesium phosphate to obtain a mixed material.

[0034] (4) Pulverize the mixed material, sieve and sieve (φ1mm), and finally mix to obtain the product of the present invention, the south...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com