Photoresist pattern trimming methods

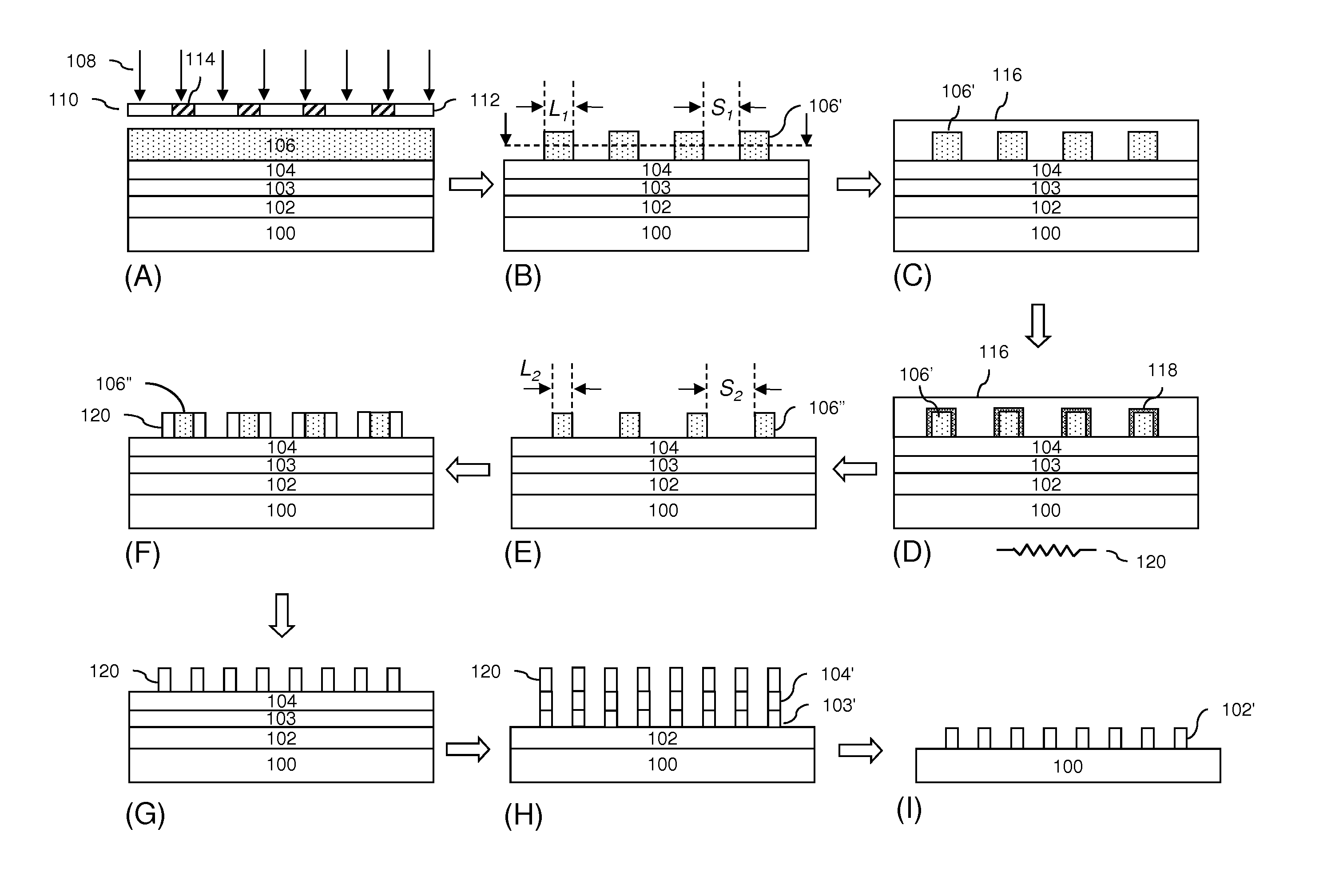

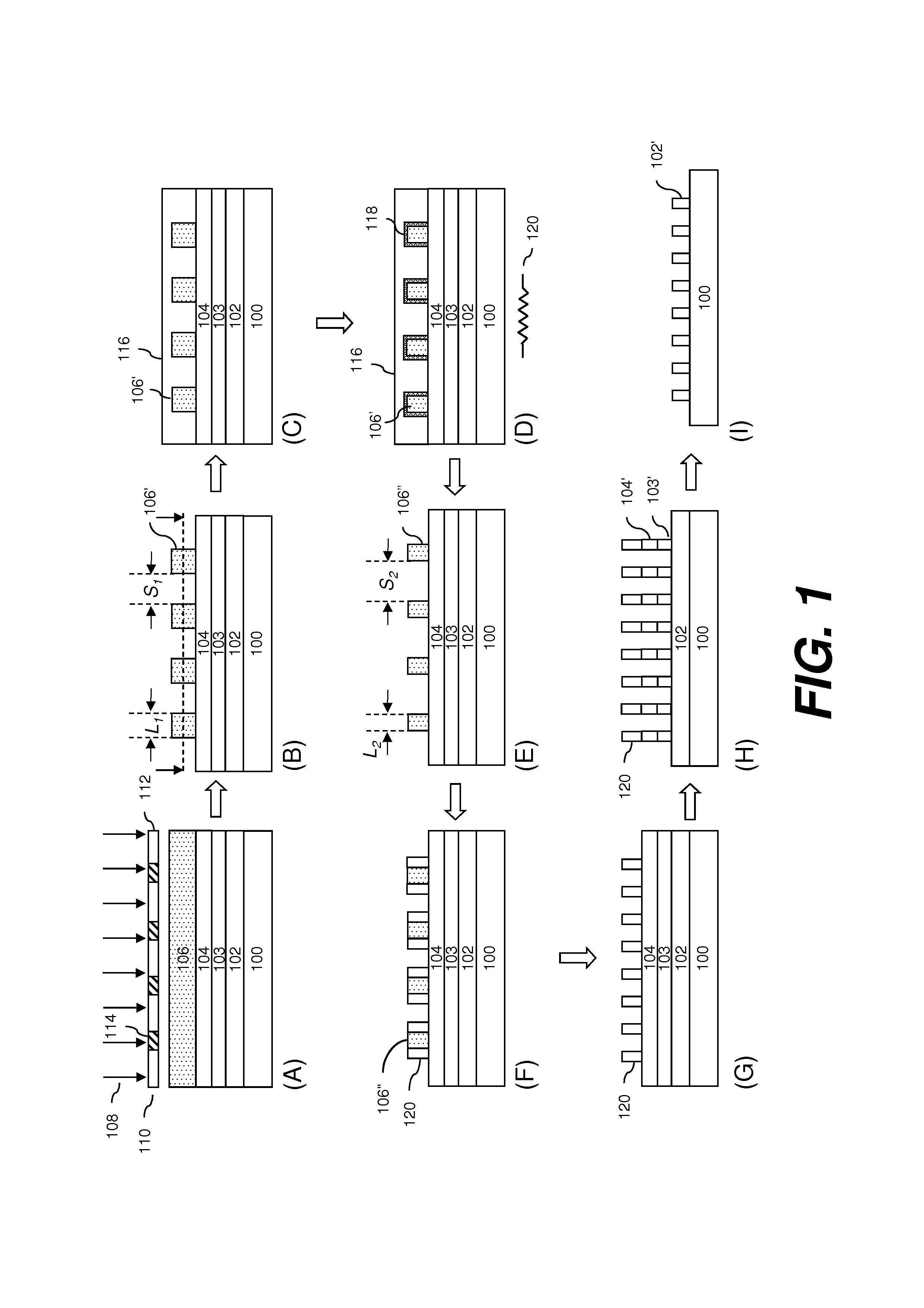

a technology of photoresist and pattern, applied in the field of electronic device manufacturing, can solve the problems of inability to achieve a good process window for isolated lines and posts through direct lithographic imaging, and the difference in solubility characteristics between exposed and unexposed regions of resist, so as to achieve a significant improvement of the process window for the formation of patterns such as isolated lines and posts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

PTC 1

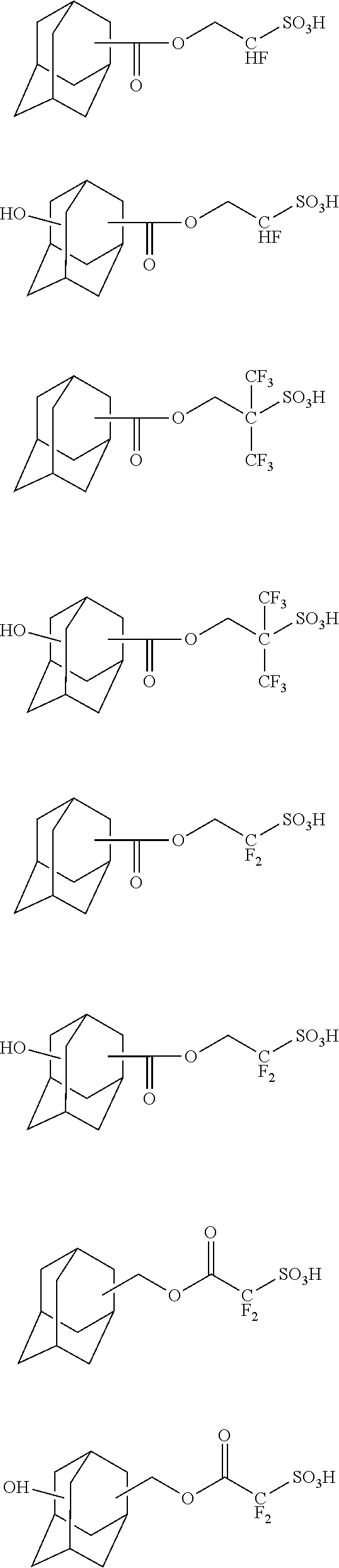

[0044]2.726 copolymer of t-butyl acrylate / methacrylic acid (7 / 3 of mole ratio), 0.170 g of perfluorobutane sulfonic acid, 19.42 decane and 77.68 2-methyl-1-butynol were mixed until all components were dissolved. The resulting mixture was filtered with a 0.2 micron Nylon filter.

example 2

PTC 2

[0045]3.271 g polymer P1, 2.1808 g polymer P2, 0.348 g perfluorobutane sulfonic acid, 56.52 g 4-methyl-2-pentynol and 37.68 g di(isopentyl)ether were mixed until all components were dissolved. The resulting mixture was filtered with a 0.2 micron Nylon filter.

example 3

PTC 3

[0046]13.5 g polyacrylic acid, 1.5 g trifluoromethylbenzyl sulfonic acid (TFMBSA) and 85 g water were mixed until all components were dissolved. The resulting mixture was filtered with a 0.2 micron nylon filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com