Patents

Literature

46 results about "Calcium sorbate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium sorbate is the calcium salt of sorbic acid. Calcium sorbate is a polyunsaturated fatty acid salt. It is a commonly used food preservative; its E number is E203, but it is no longer allowed to be used in the European Union.

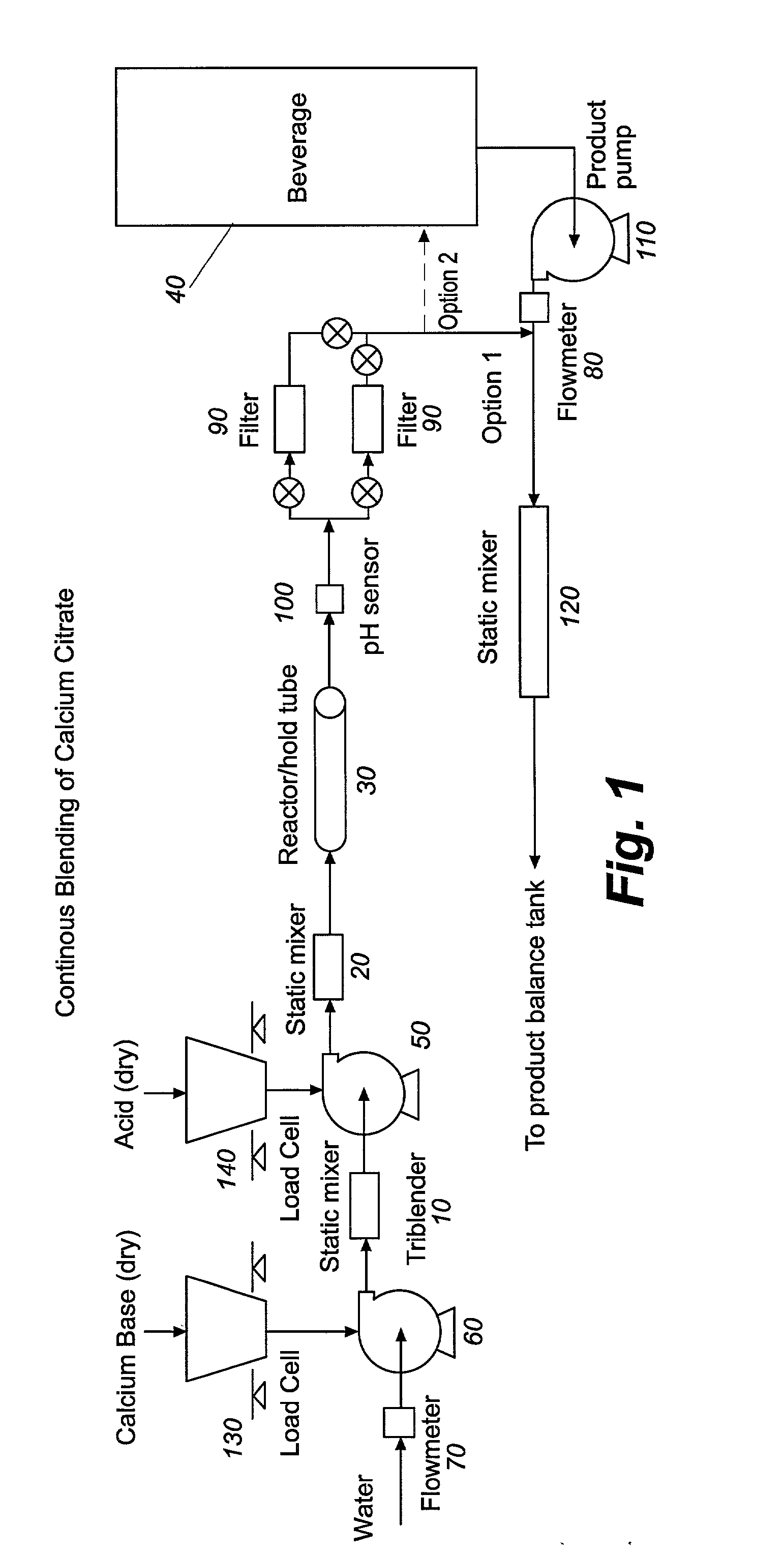

Process apparatus, and composition for calcium fortification of beverages

InactiveUS20020122866A1Inhibit productionReduce presenceFood ingredientsFood preparationCalcium hydroxideSufficient time

Process, apparatus and composition for calcium fortification of beverages are provided. The methods comprise continuously blending in water a calcium source, preferably calcium hydroxide, and an acid source for a time sufficient to produce soluble calcium salts, but with minimal precipitation. The acid source is preferably citric acid. The calcium salt solution remains in an in-line retaining reaction hold tube for the necessary period to produce calcium salt in solution without significant precipitation, and is then continuously and immediately added to a non-dairy beverage, such as orange juice, to calcium fortify the beverage. The pH of the calcium salt solution can be monitored to optimize the amount of soluble salt and minimize the amount of precipitate.

Owner:THE COCA-COLA CO

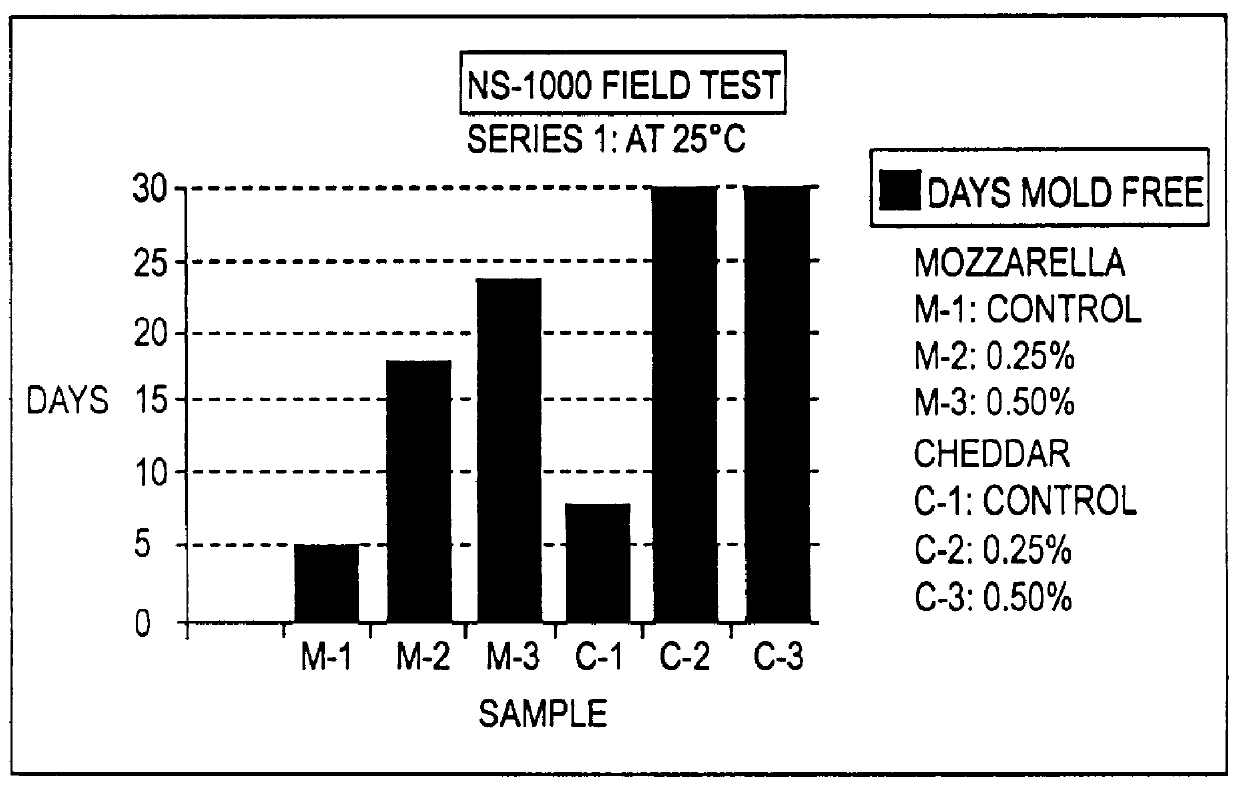

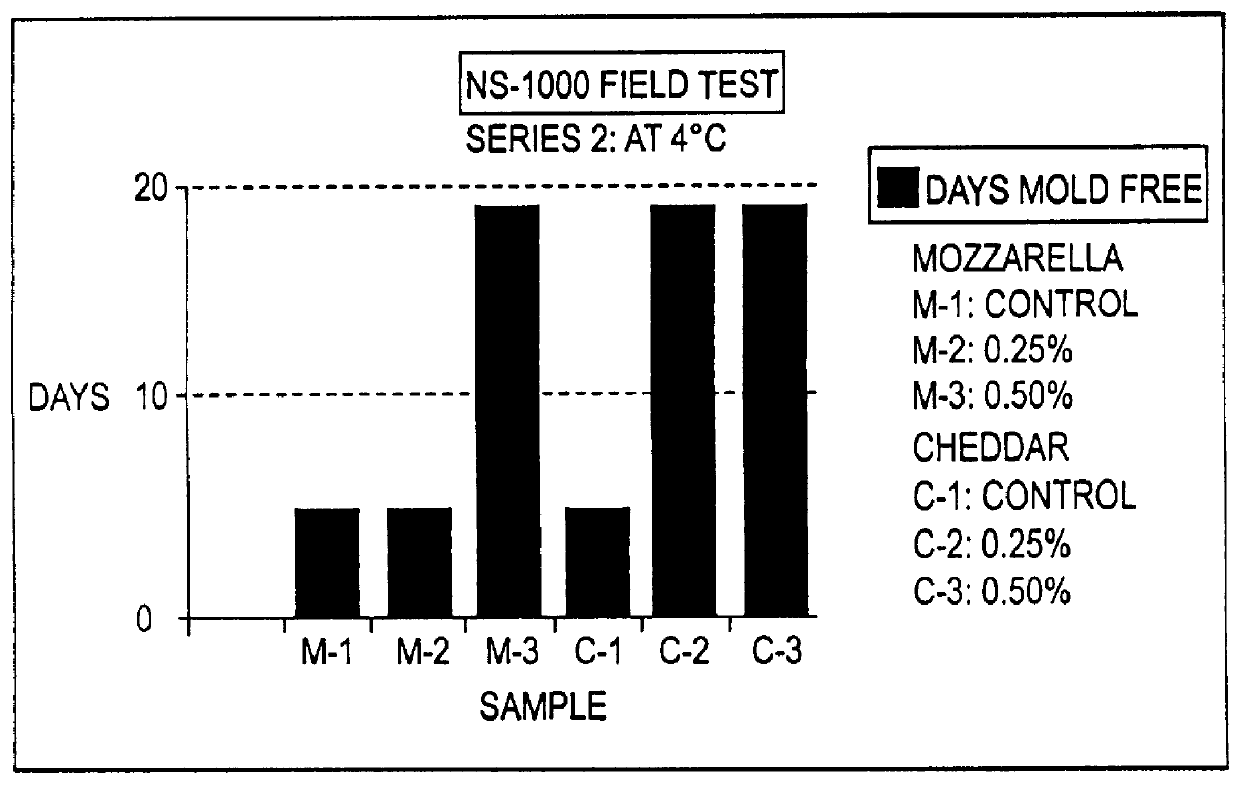

Methods of preparation and using antimicrobial products

InactiveUS6123973AEliminate bad tasteLower decomposition temperatureBiocideDough treatmentPropanoic acidSodium sorbate

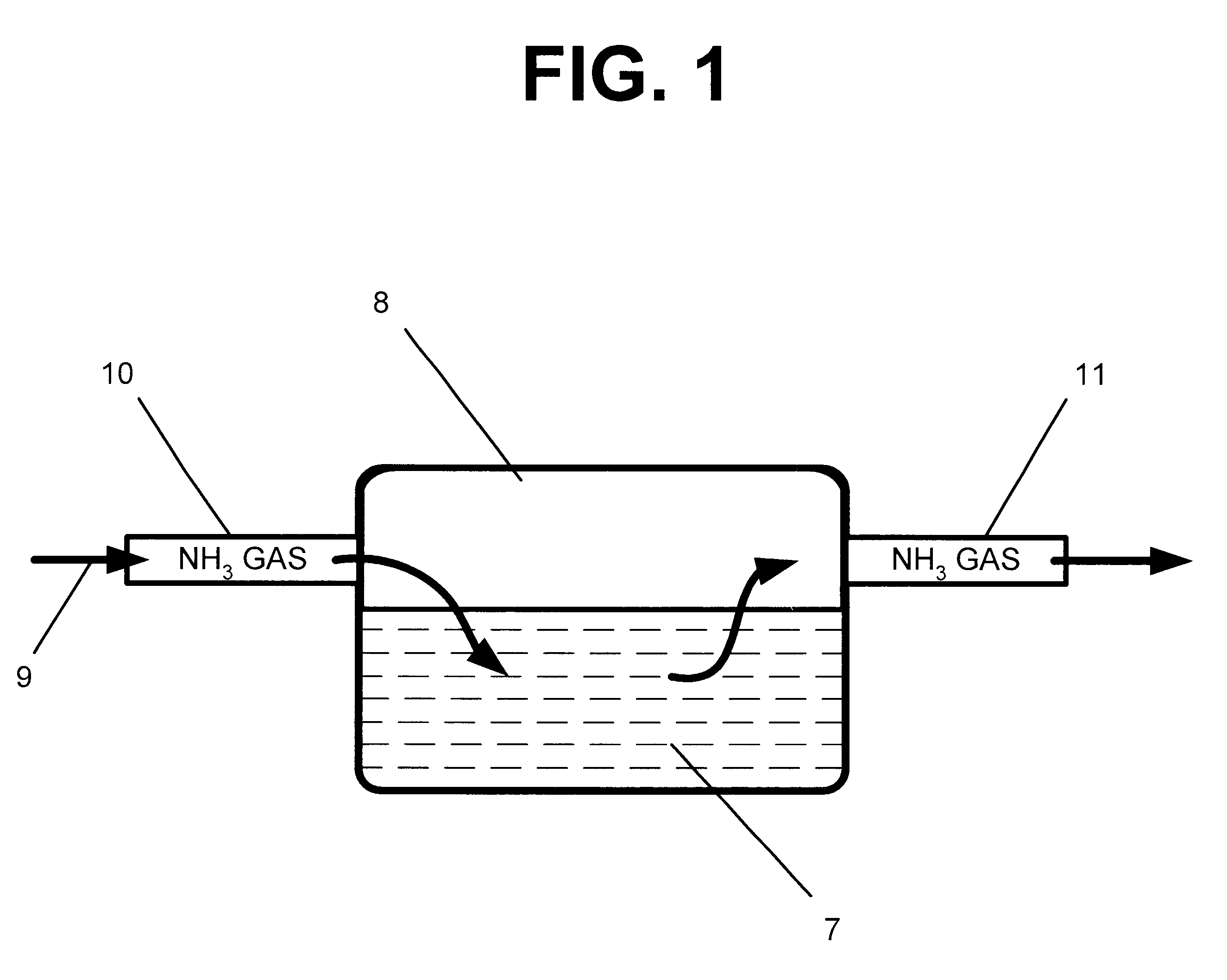

Novel antimicrobial products and methods of making and using the same are shown, whereby the products can be used in the same or greater percentages as conventional microbial growth inhibitors without imparting an off-flavor, taste, color or odor to the products in which they are used. The antimicrobial products are formed by reacting azodicarbonamide or an ammonia gas with a compound selected from the group consisting of benzoic acid, sodium benzoate, calcium benzoate, potassium benzoate, acetic acid, sodium diacetate, paraben, niacin, calcium acetate, calcium diacetate, citric acid, lactic acid, fumaric acid, sorbic acid, sodium sorbate, calcium sorbate, potassium sorbate, propionic acid, sodium propionate, calcium propionate, potassium propionate and mixtures thereof. In one embodiment, the product is prepared by placing a layer of azodicarbonamide on a substrate and covering the layer with a gas permeable separator. The antimicrobial compound is then added on top of the separator, and the combination is heated to form the final product. In another embodiment, the product is prepared by exposing the antimicrobial compound to an ammonia gas. The ammonia gas reacts with free acids in the antimicrobial compound to convert the free acids into ammonium salts, thereby eliminating off-flavor and off-odor of the resulting antimicrobial product. The antimicrobial products prepared according to the present invention are suitable for use in foodstuffs, sanitation products, cosmetics, pharmaceuticals, and so forth.

Owner:TILLIN

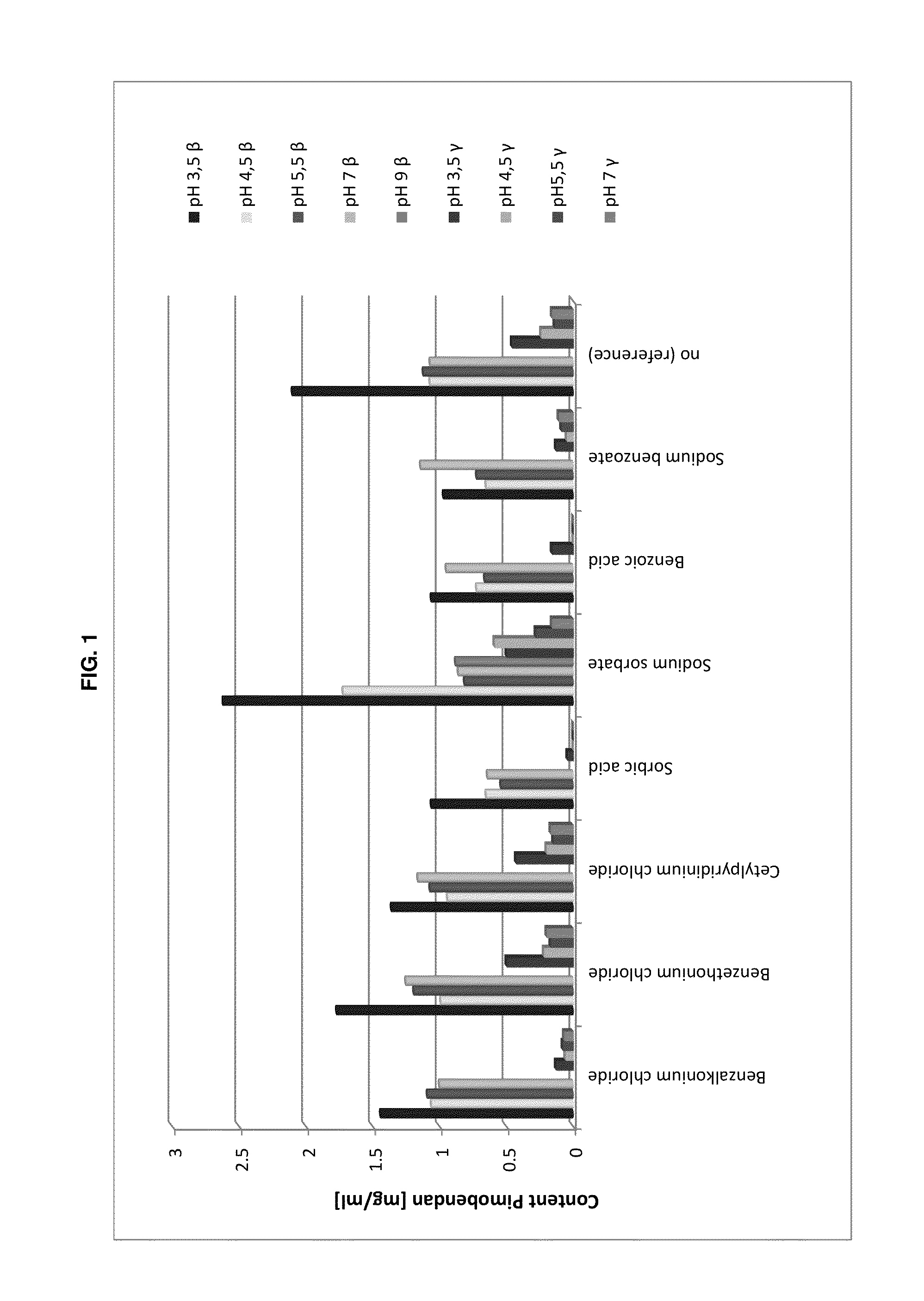

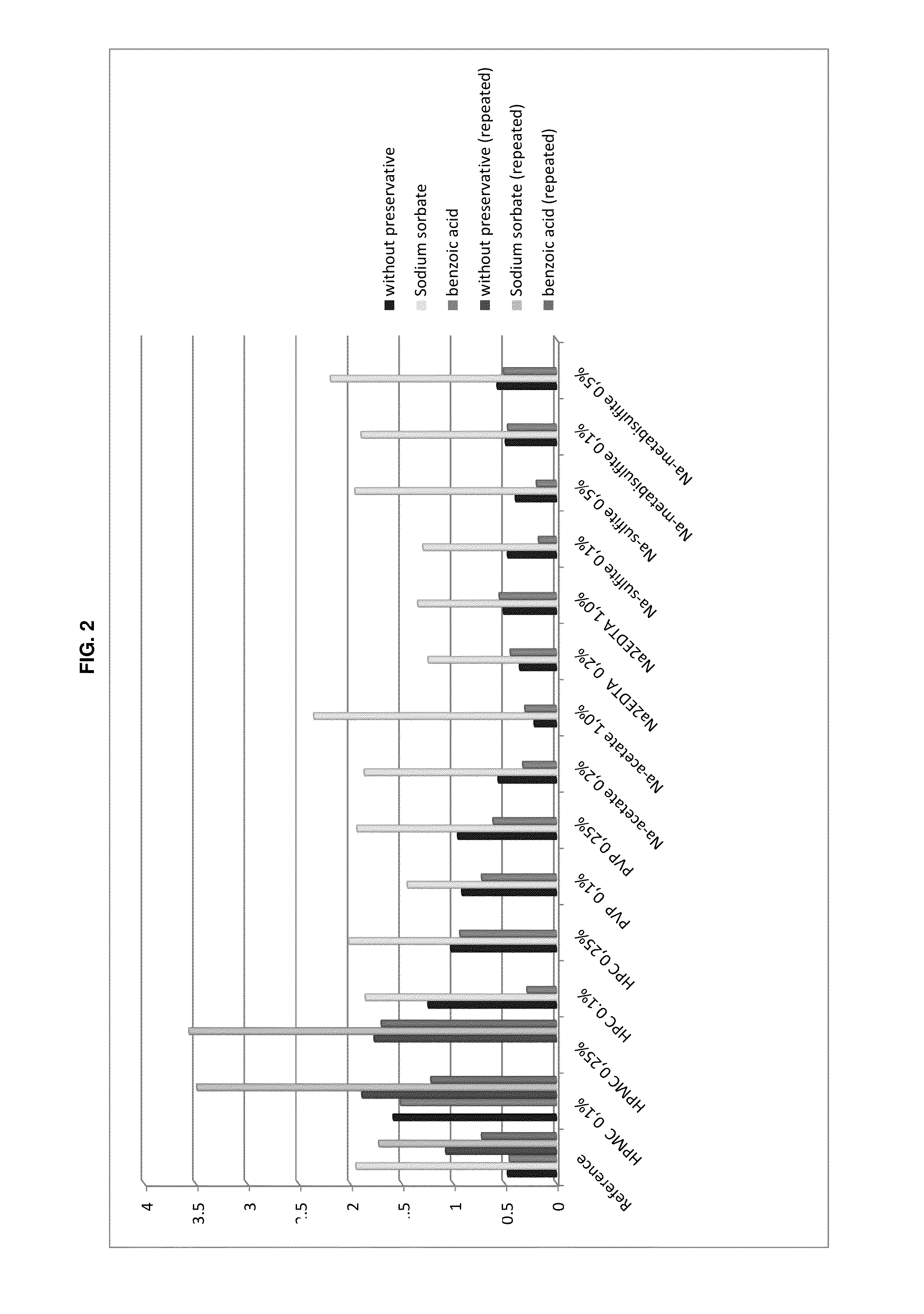

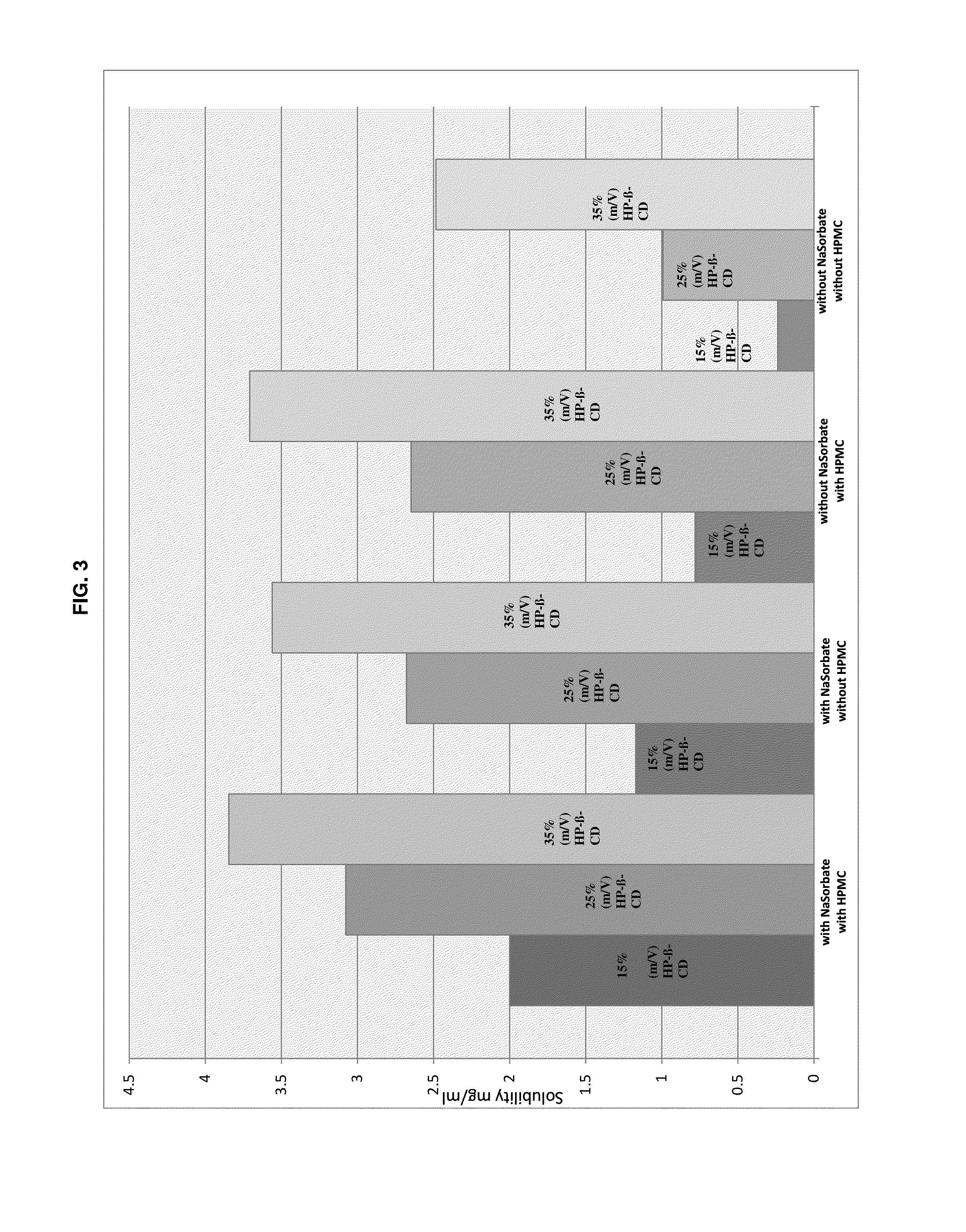

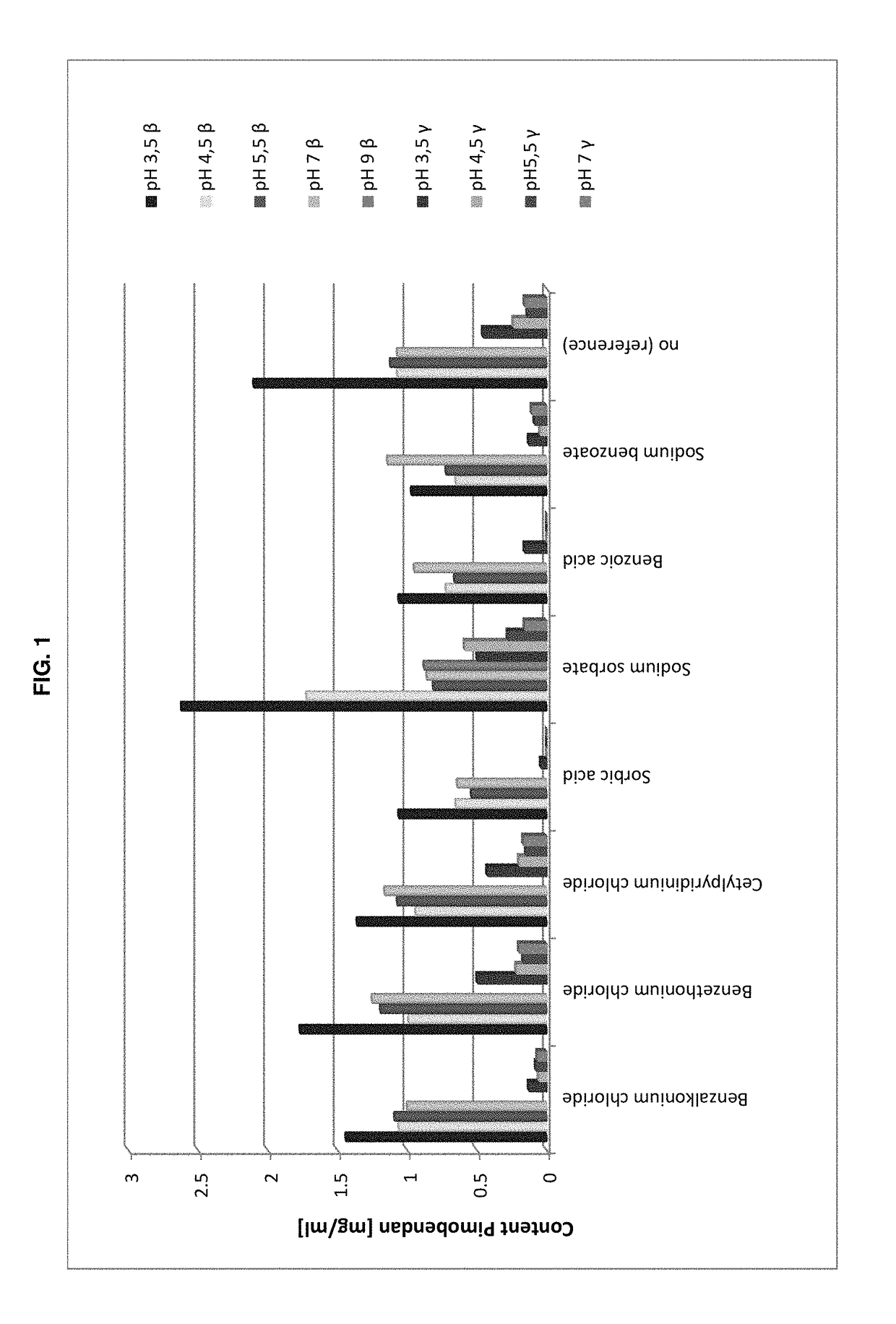

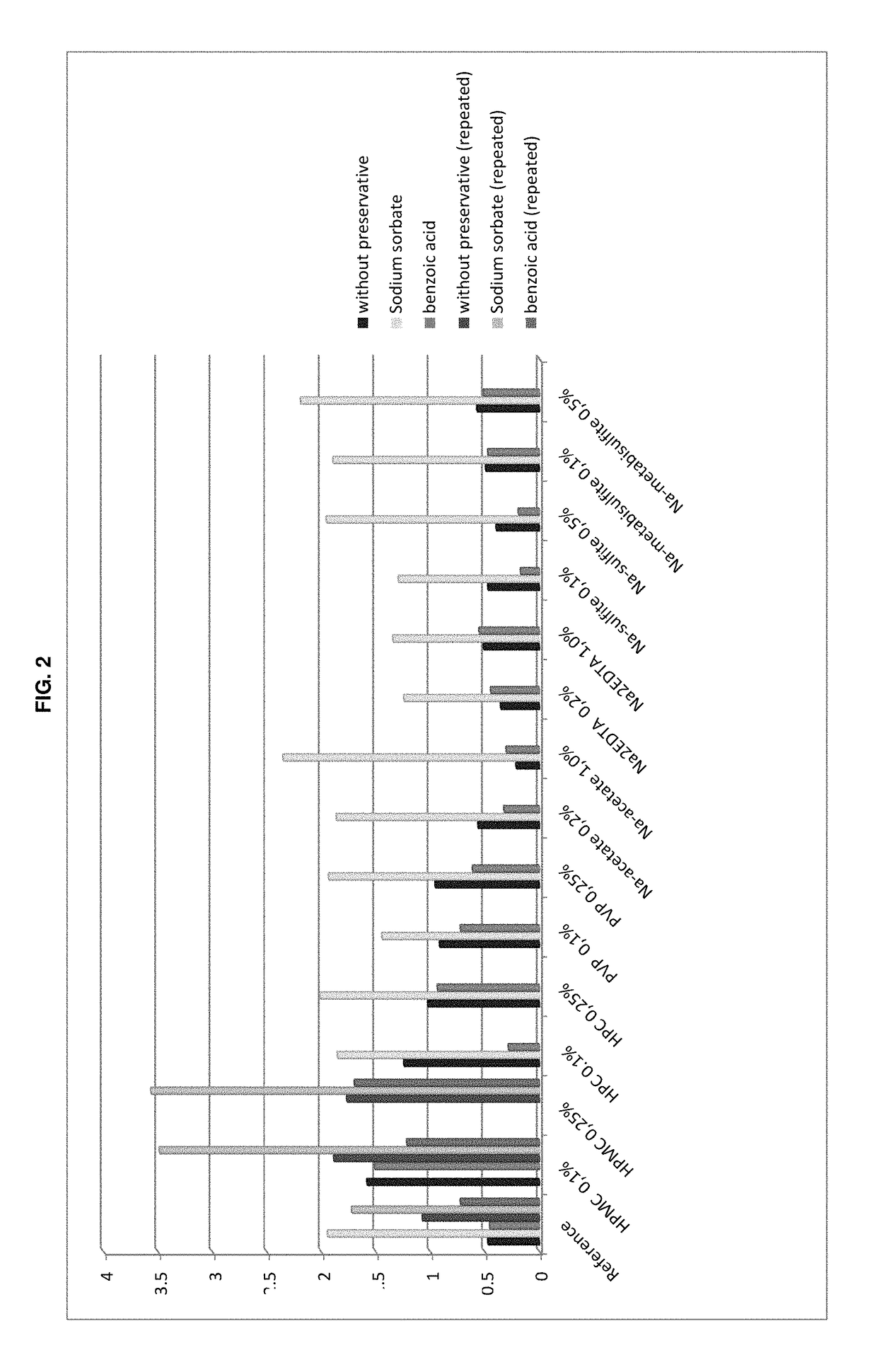

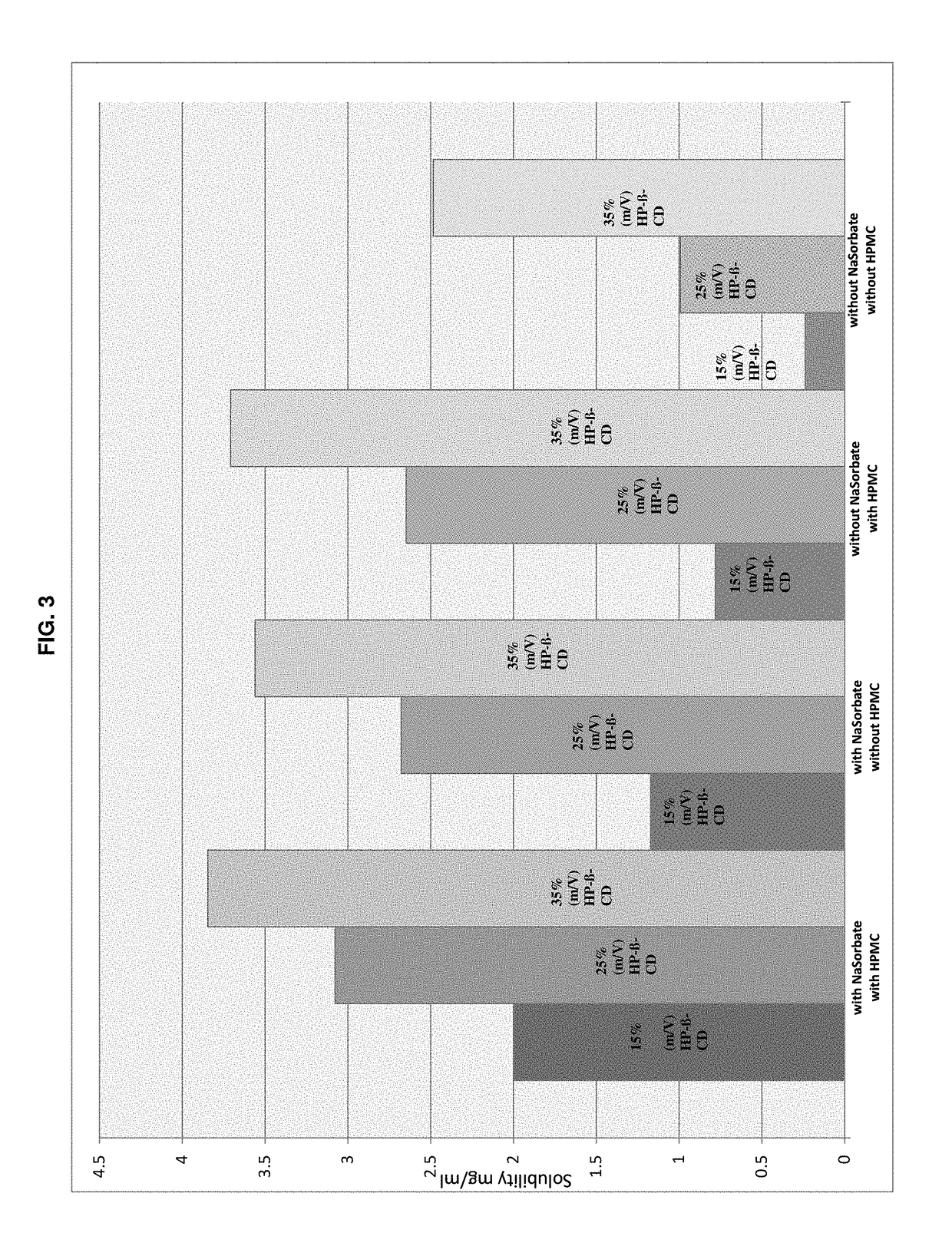

Preserved etherified cyclodextrin derivatives containing liquid aqueous pharmaceutical composition

ActiveUS20150025082A1Inhibit microbial growthRetaining its effectivenessAntibacterial agentsNervous disorderSodium acetrizoateSodium acetate

The present invention is directed to a preserved liquid aqueous pharmaceutical composition comprising one or more etherified cyclodextrin derivatives; one or more water-soluble preservatives; preferably selected from the group consisting of sorbic acid or salts thereof, preferably sodium sorbate, potassium sorbate, calcium sorbate; benzoic acid or salts thereof, preferably sodium benzoate; benzalkonium chloride; benzethonium chloride; cetylpyridinium chloride; sodium metabisulfite; sodium acetate; parabenes and salts thereof, preferably methylparabene, ethylparabene, propylparabene, butylparabene, butylparabene sodium; or combinations thereof; and at least one pharmaceutically active compound which is poorly water-soluble, very poorly water-soluble or water-insoluble. The liquid aqueous pharmaceutical composition provides an acceptable solubility of the pharmaceutically active compound, such as pimobendan, in aqueous solution whereby the water-soluble preservatives retain their effectiveness in the presence of the etherified cyclodextrin derivatives allowing the use in an oral administration form.

Owner:BOEHRINGER LNGELHEIM VETMEDICA GMBH

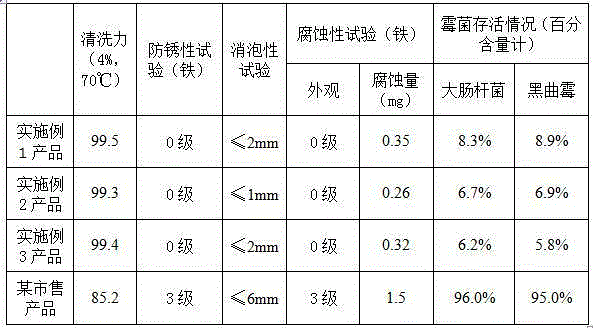

Anti-rust cleaning liquid for mechanical processing equipment

InactiveCN105296241AThe preparation process is simpleSimple processing methodSurface-active non-soap compounds and soap mixture detergentsBiotechnologyMonoglyceride

The invention relates to an anti-rust cleaning liquid for mechanical processing equipment. The anti-rust cleaning liquid consists of the following components in parts by mass: 50 to 54 parts of trisodium phosphate, 52 to 56 parts of ethoxyamine, 48 to 52 parts of octaphenyl polyoxyethyiene, 52 to 56 parts of citric acid, 48 to 52 parts of ethylene glycol butyl ether, 52 to 56 parts of benzyl triphenyl phosphorous bromide, 48 to 52 parts of malic acid, 54 to 58 parts of dichlorodifluoromethane, 48 to 52 parts of benzotriazole, 52 to 56 parts of calcium sorbate, 48 to 52 parts of caprylic / capric glycerides, 52 to 56 parts of oxalic acid, 48 to 52 parts of hard resin acid monoglyceride, 52 to 56 parts of hyclroxy acetic acid, 48 to 52 parts of biochemical fulvic acid, 48 to 52 parts of sodium nitrite, 52 to 56 parts of epoxy acid zinc, 48 to 52 parts of morpholine, 52 to 56 parts of petroleum mahogany sulfonate, 48 to 52 parts of chlorothalonil, and 1000 to 2000 parts of water. The anti-rust cleaning liquid has the advantages that the cleaning capability is better, the anti-rust and non-corrosive effects are realized, and the anti-bacteria and mildew-proof effects are realized.

Owner:龚灿锋

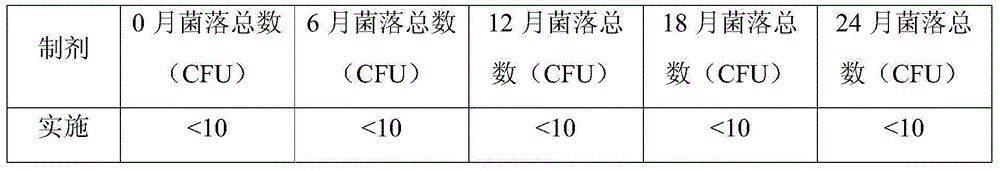

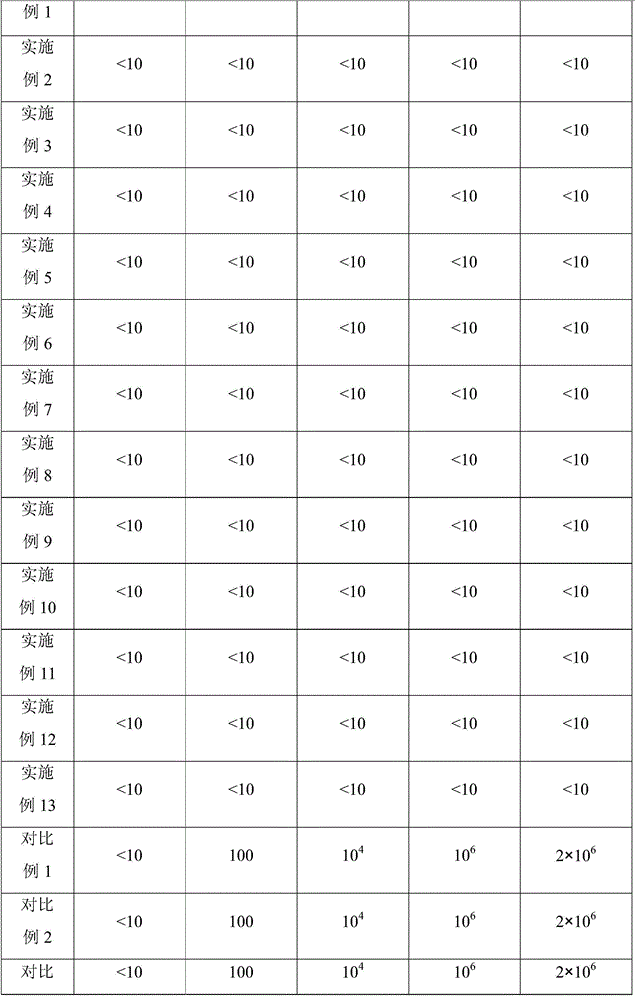

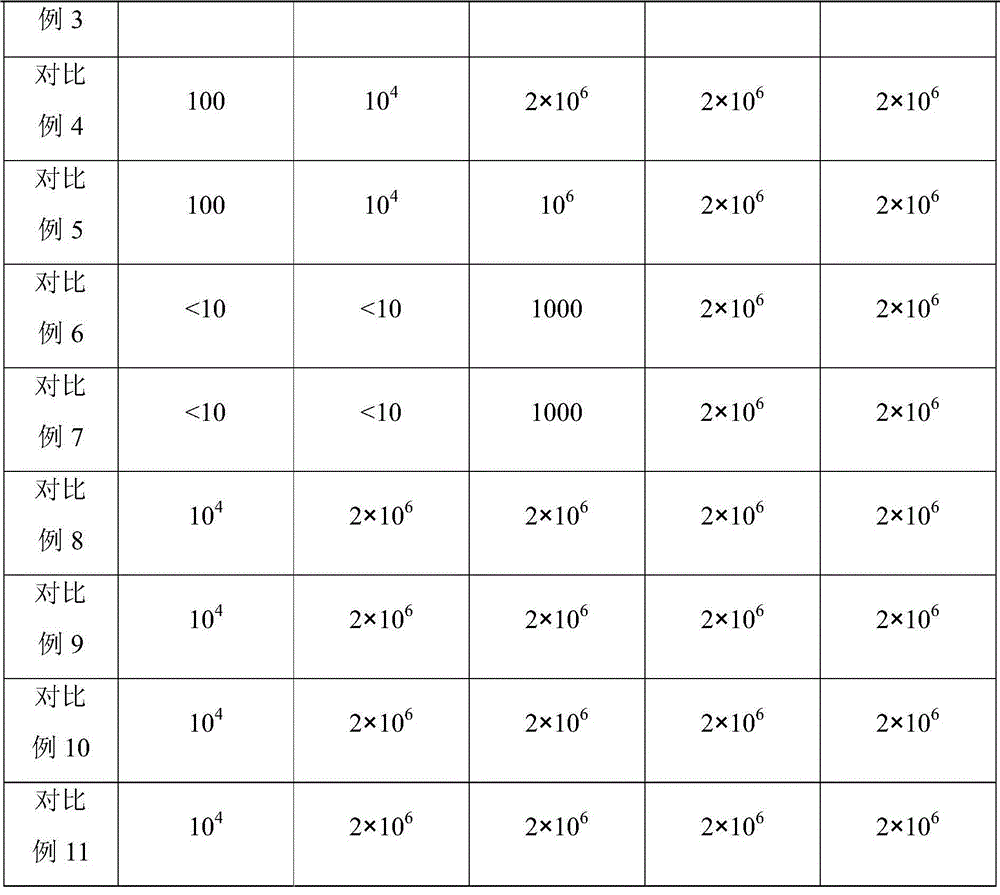

Pesticide composition, spoilage and mildew prevention composition, and spoilage and mildew prevention method

InactiveCN104365594AImprove anti-corrosion performanceLow costBiocideFungicidesBenzoic acidIsothiazolinone

The invention relates to a pesticide composition, a spoilage and mildew prevention composition, and a spoilage and mildew prevention method. The spoilage and mildew prevention composition comprises a component (I) and a component (II) according to a mass ratio of 0.05-20:1, and the component (I) is one or more selected from benzoic acid, sodium benzoate, sorbic acid, calcium sorbate, potassium sorbate and methylparaben; and the component (II) is one or two selected from isothiazolinone A and isothiazolinone B. The spoilage and mildew prevention composition can significantly improve the spoilage resistance of a preparation and reduce the cost, and can solve the problems of layering, qi distention and stink caused by spoilage and mildew of the above pesticide preparation. The composition has the advantages of mature component and technology, low price, easy obtaining, simple operation, and can effective guarantee of mildew and bacterium prevention for 2 years.

Owner:JIANGSU SEVENCONTINENT GREEN CHEM CO LTD

Cleaning agent of printing ink and preparation method thereof

ActiveCN103525168AImprove craftsmanshipReduce pollutionChemical paints/ink removersSide effectPolyethylene glycol

The invention discloses a cleaning agent of printing ink. The cleaning agent is characterized by comprising the following materials in parts by weight: 1-3 parts of diethanol amine, 1-2 parts of oxalic acid, 5-10 parts of sodium benzoate, 9-12 parts of propylene glycol, 13-15 parts of alcohol, 6-8 parts of polyethylene glycol, 1-2 parts of coconut fatty acid alkanolamide, 3-5 parts of polysorbate 80, 2-3 parts of calcium sorbate, 1-2 parts of sodium hypochlorite, 10-12 parts of dipropylene glycol mono butyl ether, 4-5 parts of additives and 100-110 parts of water. The cleaning agent disclosed by the invention has the advantages that due to addition of the additives, the processing property of the cleaning agent is improved, and the toxic and side effects and the pollution to environment of the cleaning agent are alleviated; the ink dissolving and diluting capabilities of the cleaning agent are excellent, no toxicity and pollution are caused, the cleaning agent is not flammable and combustible, the damage on rubber rollers of a printing machine is low, the use is convenient and the cost is low.

Owner:HEFEI ALL ROUND POLYMER MATERIAL FACTORY

A flocculating agent for treating domestic sewage

InactiveCN106241982ANothing producedNo corrosionWater/sewage treatment by flocculation/precipitationSodium bicarbonateIsooctyl acrylate

The invention relates to a flocculating agent for treating domestic sewage. The flocculating agent comprises polyol phosphate, alkylamine polyoxyethylene ether oxide, etidronic acid, polyamino polyether methylene phosphonate, calcium sorbate, methoxybenzoic acid, hydroxyquinoline, methylene dithiocyanate, potassium peroxydisulfate, nanometer titanium dioxide, wollastonite powder, sodium thiosulfate powder, sodium bicarbonate, nanometer zinc oxide, sodium dodecyl sulfate, sodium dodecylbenzenesulfonate, magnesium stearate, a quaternary ammonium salt, coal tar, N-ethylmorpholine, carbon tetrachloride, pentadecanol, starch phosphate, 2-ethylhexyl acrylate, butylated hydroxyanisole, dimethyl diallyl ammonium chloride, aniline, tryptophan, threonine, polycarbosilane and deionized water. The flocculating agent is high in reaction speed, and free of generation of toxic and harmful gas in a process. A product after the reaction is stable and does not decompose into toxic compounds. The flocculating agent is efficient, nontoxic, safe to human bodies before and after the reaction and high in sewage treating efficiency.

Owner:权周越

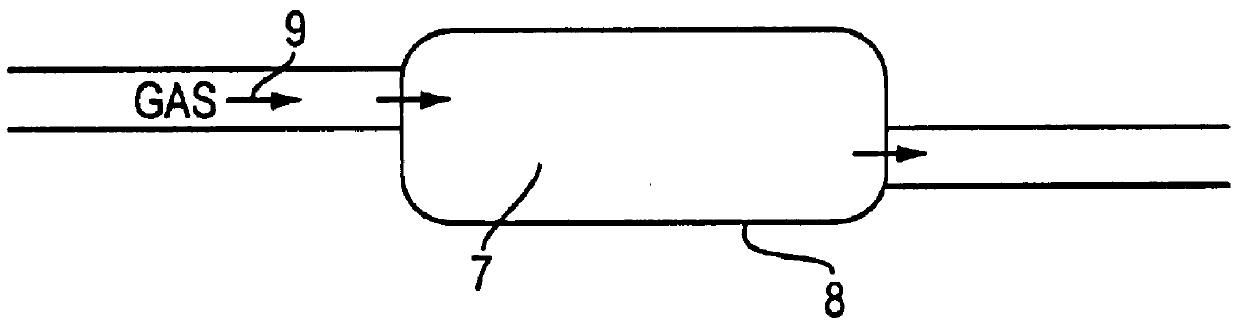

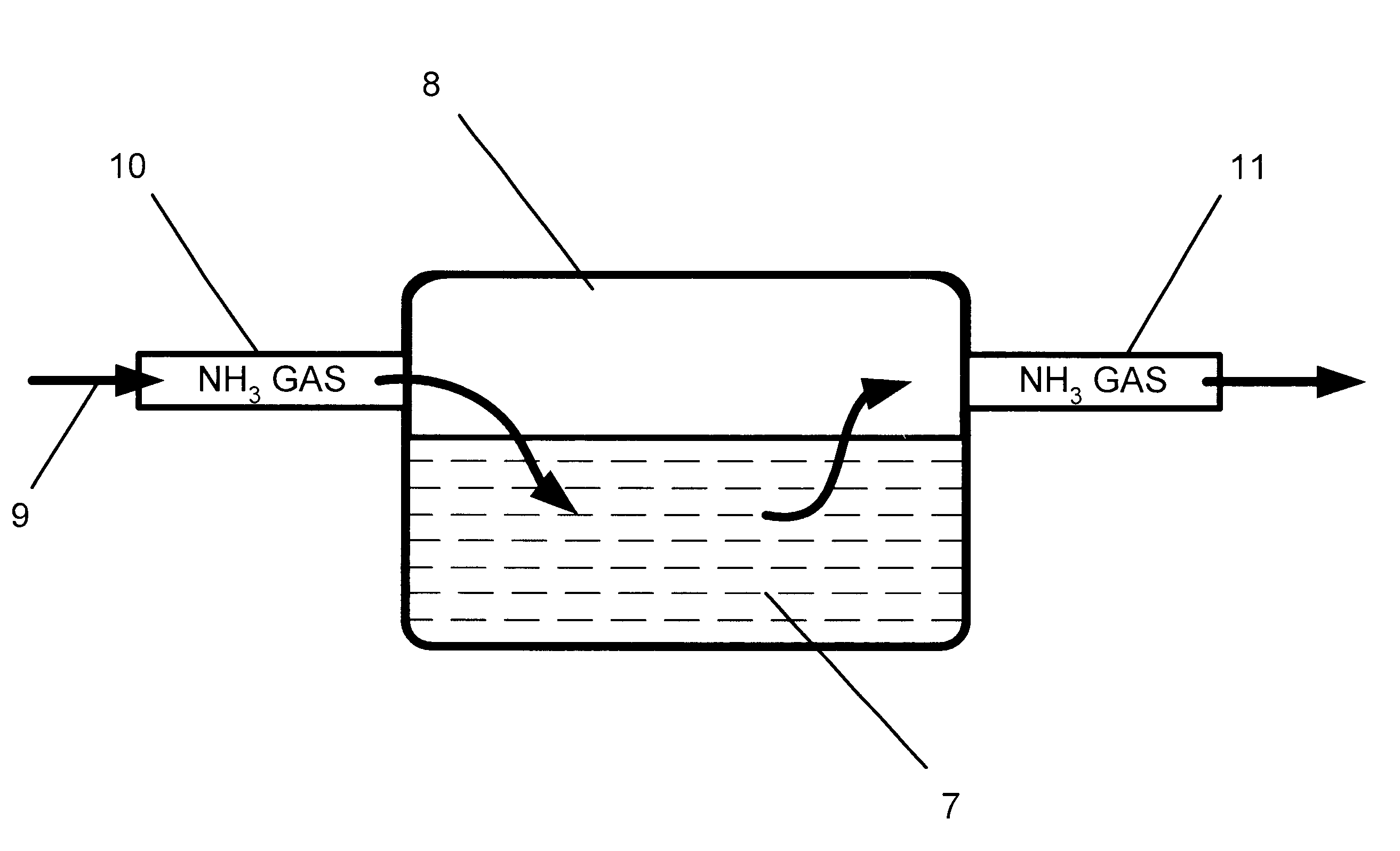

Method of treating commercial grade products to remove undesirable odors and flavors

A method of treating antimicrobial products, dairy products, pharmaceutical products and other products having offensive tastes or odors to remove the off-odors and off-tastes from the products. The method involves exposing a selected commercial grade product that contains a small amount of free acid impurities to an ammonia gas. The ammonia gas reacts with the free acid impurities to convert the free acids into ammonium salts, thereby reducing or eliminating the off-flavor and off-odor of the product. The products to be treated include antimicrobial products selected from the group consisting of sodium benzoate, calcium benzoate, potassium benzoate, sodium diacetate, paraben, niacin, calcium acetate, calcium diacetate, sodium sorbate, calcium sorbate, potassium sorbate, sodium propionate, calcium propionate, potassium propionate and mixtures thereof; dairy products selected from the group consisting of casein, whey, skim milk powder, and calostrum; pharmaceutical products selected from the group consisting of acetaminiphen, aspirin, ibuprophen, dextromethorphan hydrobromide, guaejenesin, paracetamol, and sodium erythorbate; and various other products selected from the group consisting of butylate hydroxy tolulene, polydextrose powder, sodium acid sulfate, and sodium diacetate. The common characteristic of the commercial grades of each of these products is that they contain a small amount of free acid impurities that react favorably with ammonia gas.

Owner:TILLIN

Bacteria-removal environment-friendly laundry detergent

InactiveCN106350247ALow costReduce manufacturing costNon-ionic surface-active compoundsDetergent perfumesBacteria removalStain

The invention relates to a bacteria-removal environment-friendly laundry detergent. The laundry detergent comprises the following components in parts by weight: 1.3-2.5 parts of an essence, 2-3 parts of alkyl polyglucosides, 1.4-2 parts of sodium citrate, 1.5-1.8 parts of calcium sorbate, 1-2 parts of an orange peel extracting solution, 3-5.6 parts of a folium artemisiae argyi extracting solution, 2-2.7 parts of a garlic extracting solution and 30-34 parts of water. According to the laundry detergent, water is general tap water, so that compared with pure water, the cost is greatly lowered; different formulae are formulated according to the characteristics of different blots, so that the production cost is lowered, the blots can be removed in a targeted manner, and the environmental protection is realized during the removal of bacteria.

Owner:曹平

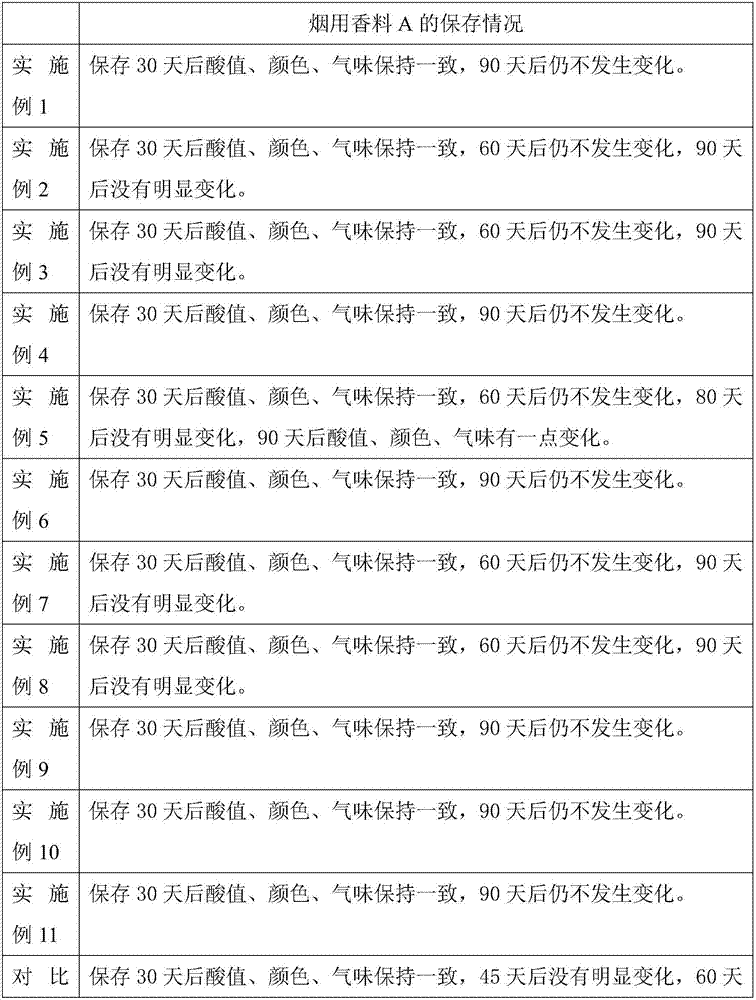

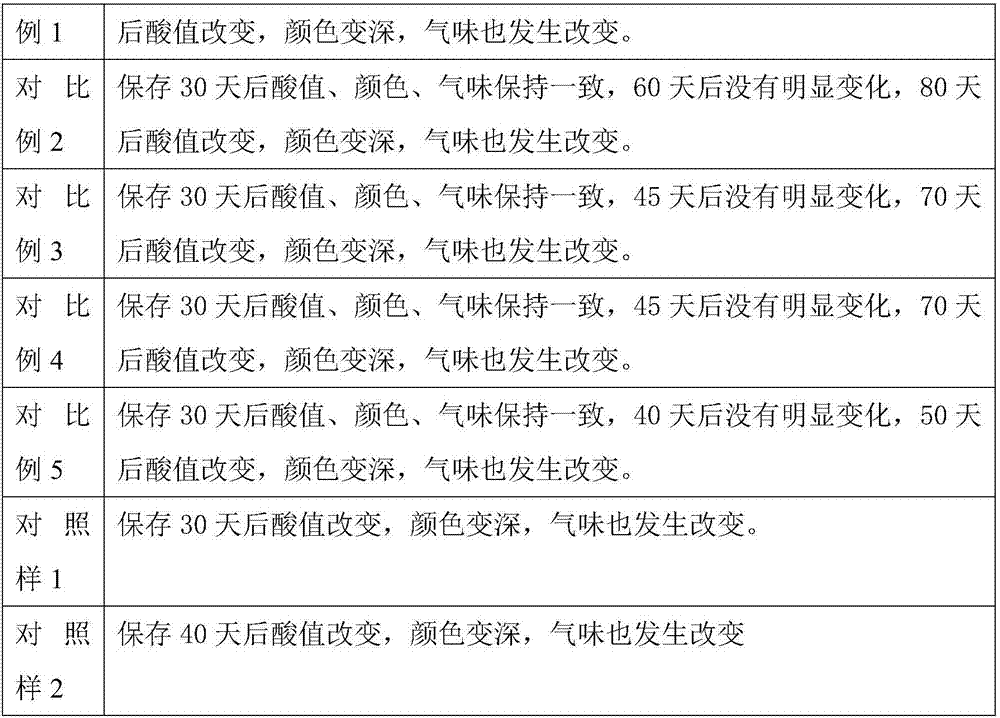

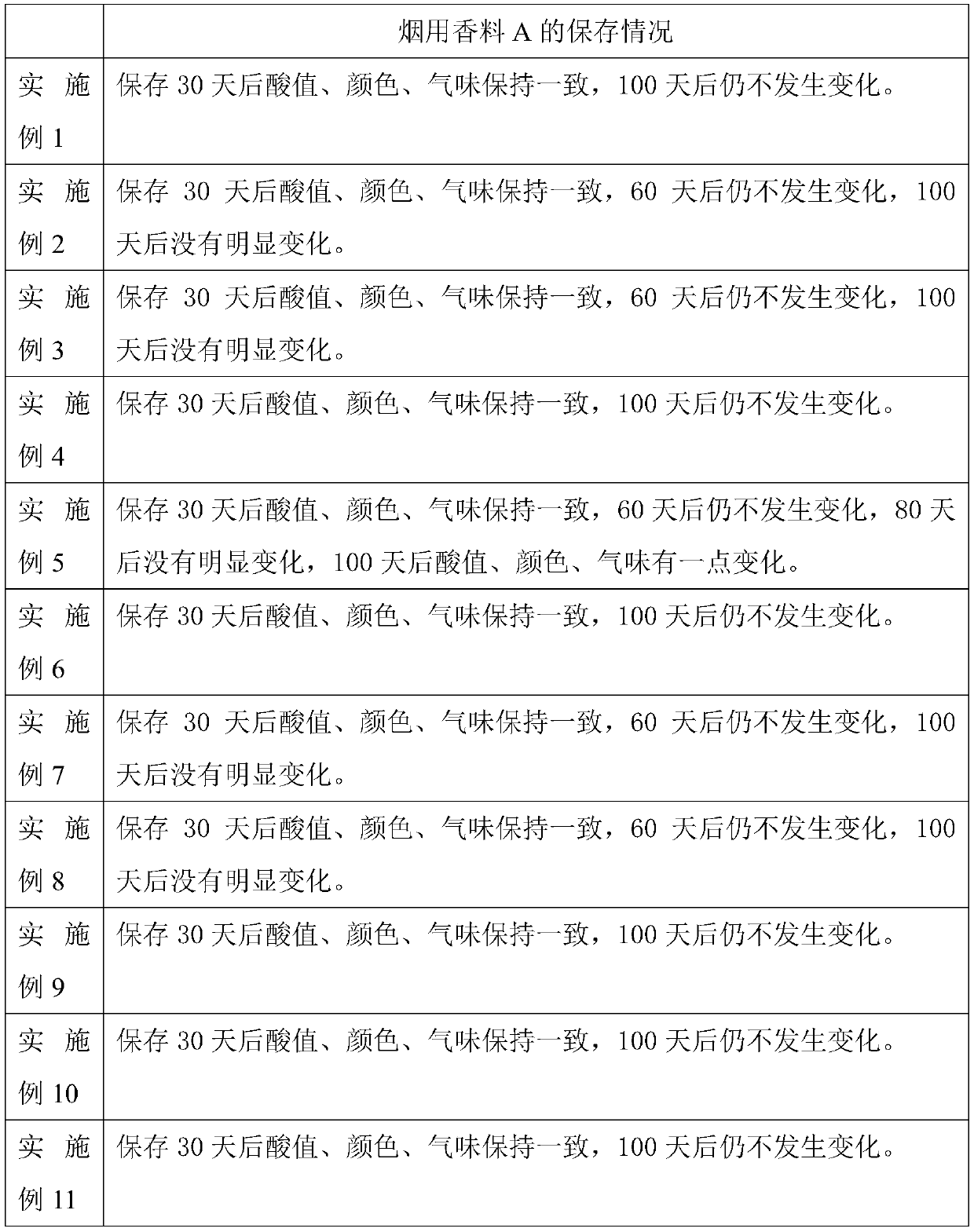

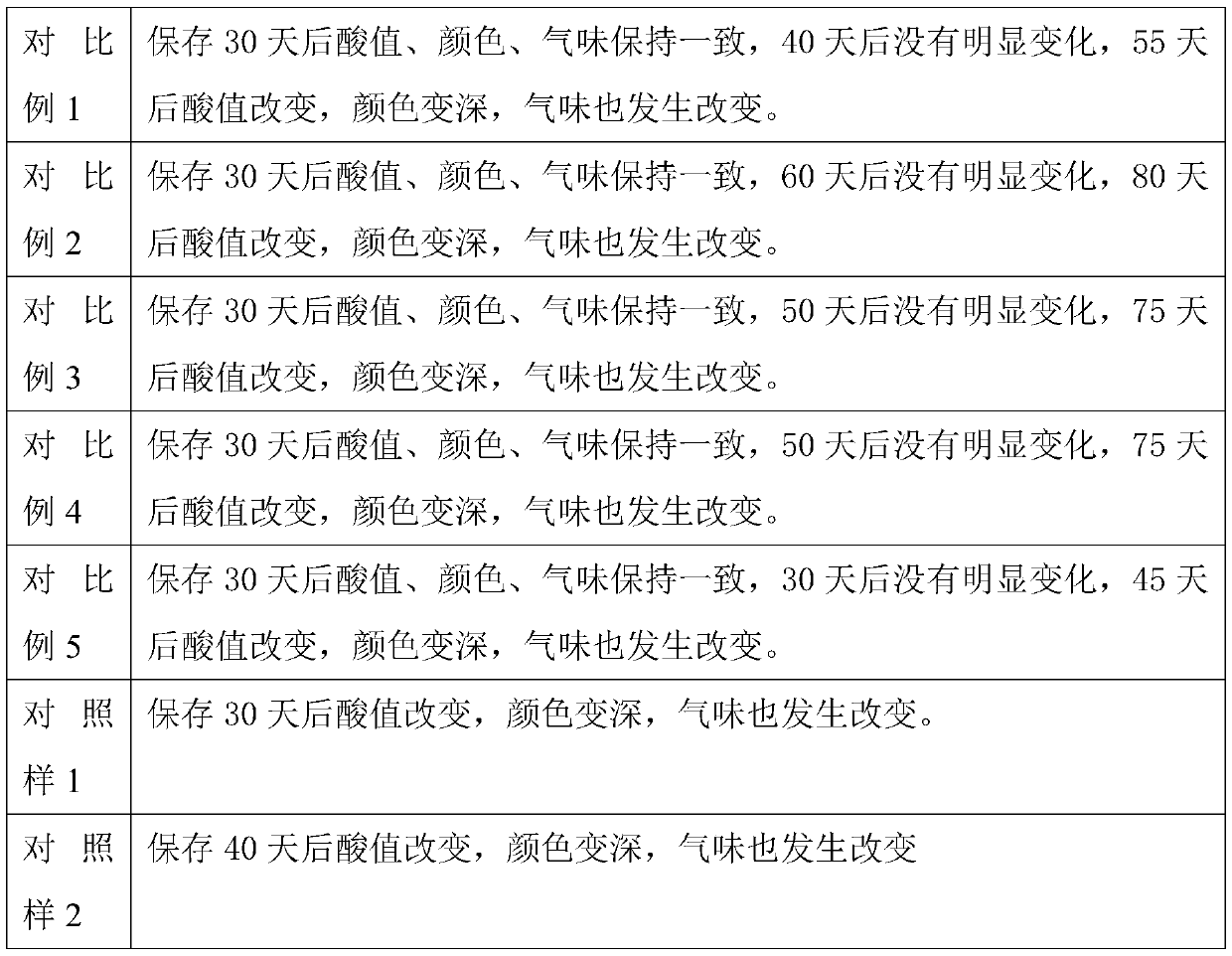

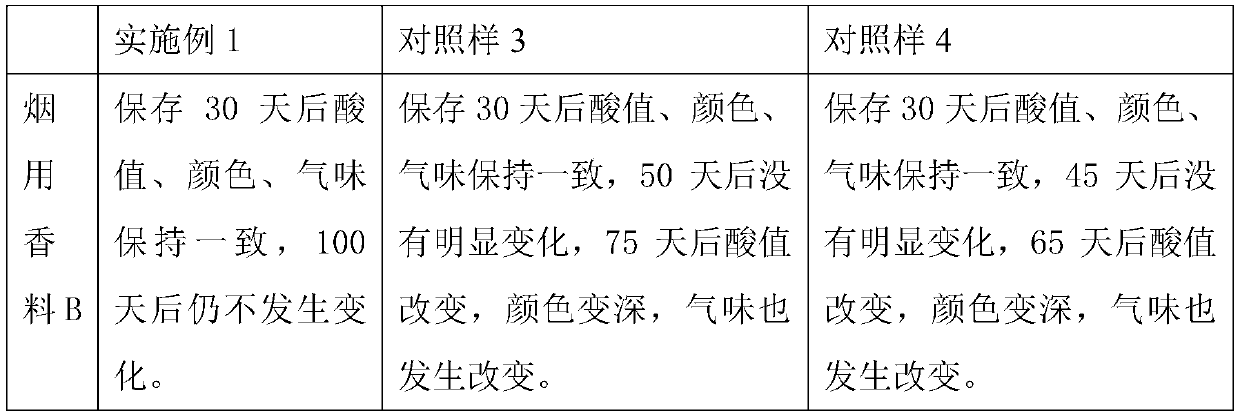

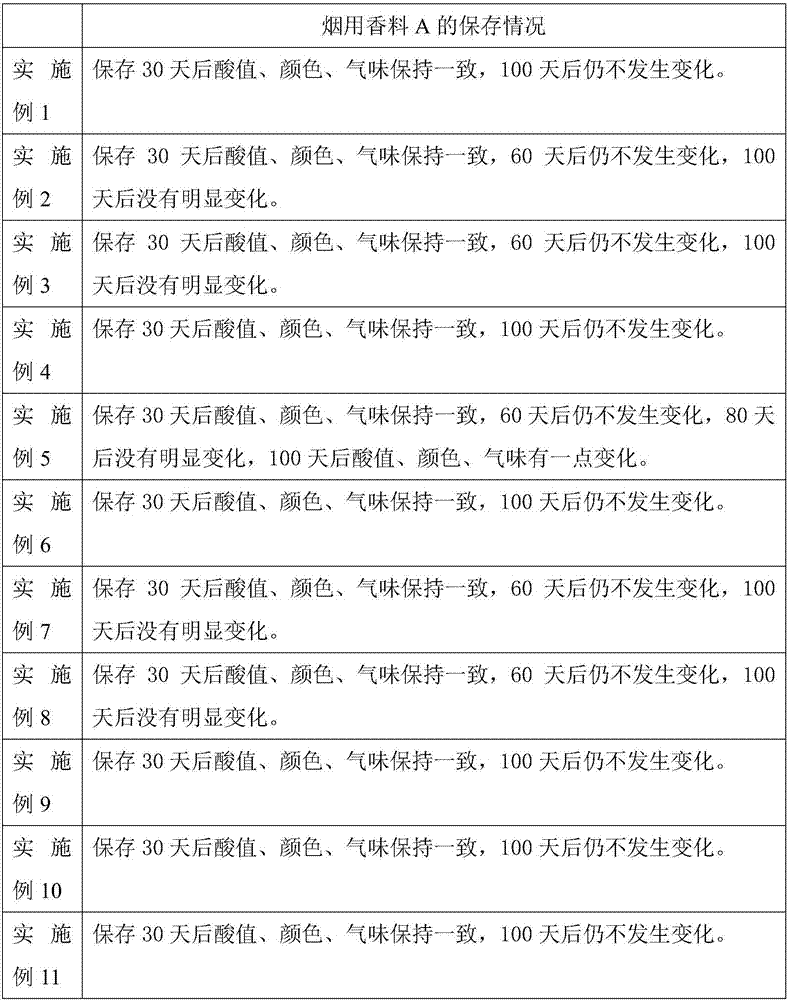

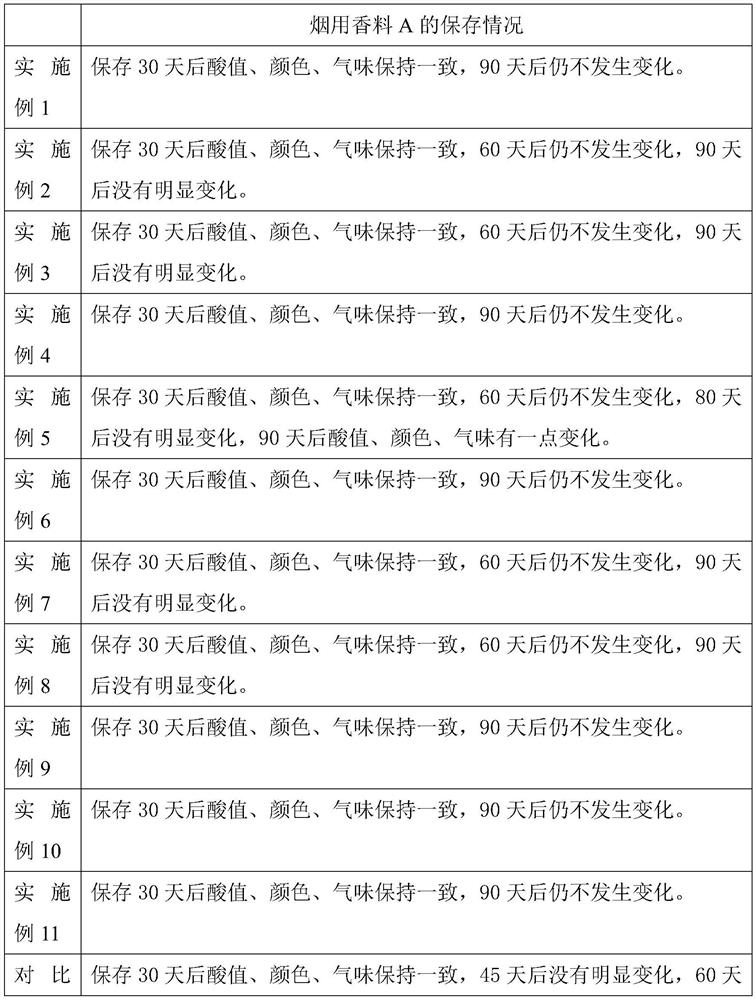

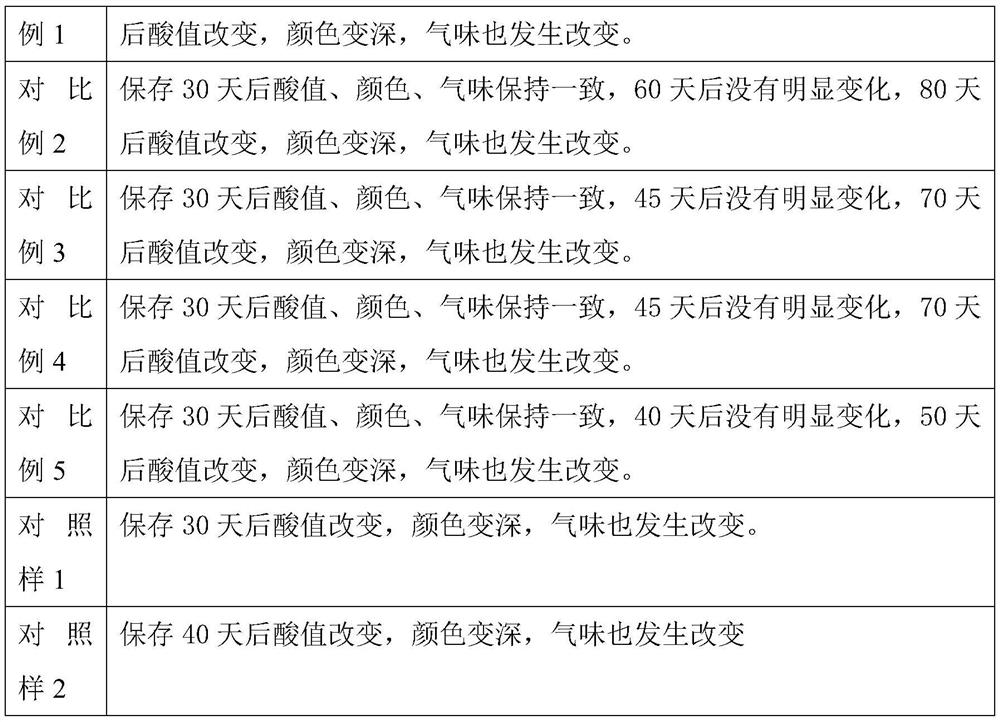

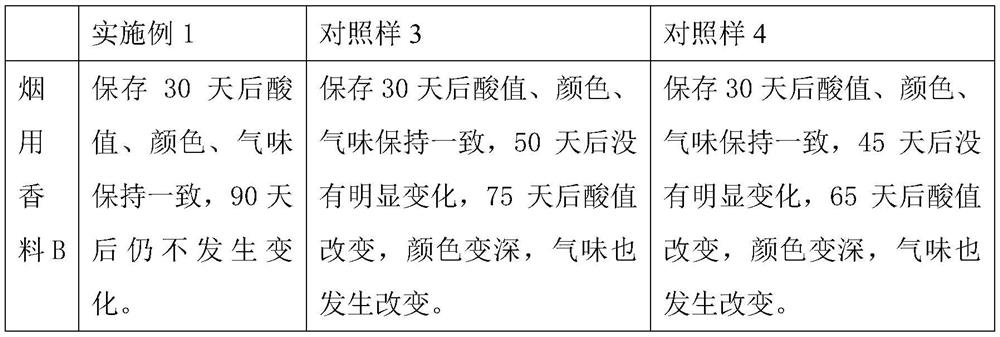

Additive for prolonging shelf life of tobacco flavor

ActiveCN107365627AGrowth inhibitionExtended shelf lifeTobacco preparationEssential-oils/perfumesMicroorganismFlavor

The invention provides an additive for prolonging the shelf life of a tobacco flavor. The additive contains the following components in percentage by mass: 3-5% of sorbic acid, 3-5% of potassium sorbate, 3-5% of calcium sorbate and 0.1-1% of nicotine; and a solvent for the additive is a composition of water and an organic solvent. The additive provided by the invention can effectively inhibit the growth of microorganisms, prolong the shelf life of the tobacco flavor and improve the stability of the components of the tobacco flavor. Besides, the additive provided by the invention does not influence the original fragrance or scent of the tobacco flavor.

Owner:CHINA TOBACCO GUANGDONG IND

Trace hydrogen sulfide detection reagent and preparation method thereof

InactiveCN104391080ASensitive detectionReasonable formulaMaterial analysisEthylic acidCopper sulfate

The invention relates to a trace hydrogen sulfide detection reagent and a preparation method thereof, belonging to the field of detection reagents. The trace hydrogen sulfide detection reagent is prepared from the following raw materials in parts by weight: 14-26 parts of copper sulfate pentahydrate, 10-18 parts of butyl acetate, 1-5 parts of zinc sulfate, 4-12 parts of sulfamic acid, 8-24 parts of sodium citrate, 5-12 parts of calcium sorbate, 3-12 parts of citric acid, 3-10 parts of dodecyl alcohol and 32-42 parts of water. The trace hydrogen sulfide detection reagent has a reasonable formula, is extremely sensitive to the detection of hydrogen sulfide, and can be used for detecting trace hydrogen sulfide; and the lowest detection amount of hydrogen sulfide can be 0.01mg / L, the detection time is short and the detection efficiency is high.

Owner:DONGCHEN LEADER TESTING

Food cleaning agent

InactiveCN102676316AGood decontamination and sterilization abilityEasily biodegradableNon-ionic surface-active compoundsDetergent compounding agentsSucroseCleansing Agents

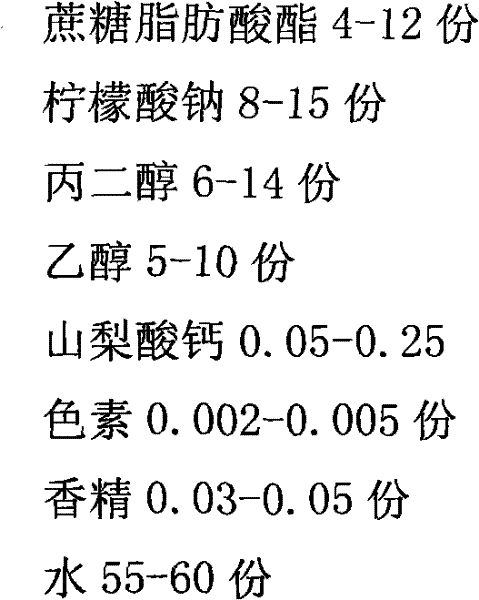

The invention discloses a food cleaning agent, which is prepared from the following components in parts by weight: 4-12 parts of sucrose fatty acid ester, 8-15 parts of sodium citrate, 6-14 parts of propylene glycol, 5-10 parts of ethanol, 0.05-0.25 part of calcium sorbate, 0.002-0.005 part of pigment, 0.03-0.05 part of essence and 55-60 parts of water. The food cleaning agent disclosed by the invention is a concentrated formula, has good decontaminating and degerming abilities, is safe and environment-friendly, and is easy to biodegrade without polluting the environment.

Owner:周维新

Automobile ornament cleaning agent

InactiveCN106590957ANo damageImprove decontamination abilityOrganic detergent compounding agentsSurface-active detergent compositionsCleansing AgentsTert butyl

The invention relates to an automobile ornament cleaning agent. The automobile ornament cleaning agent is prepared from, by mass, 5-15 parts of ethoxyamine, 4-10 parts of primary alcohol ethoxylate, 5-12 parts of benzyl triphenylphosphonium bromide, 1-6 parts of calcium sorbate, 0.1-0.7 part of propylene glycol, 4-16 parts of camphor oil, 2-10 parts of dodecyl alcohol, 2-6 parts of sodium benzoate, 3-8 parts of turpentine oil, 3-8 parts of menthol, 4-14 parts of sodium citrate, 25-50 parts of starch, 3-9 parts of butyl cellosolve, 10-30 parts of tert-butyl-4-hydroxyanisole and 100-600 parts of deionized water. The cleaning agent has the high decontamination effect, can have the high cleaning effect on oil stained substances and some contaminants not likely to be removed, the maintenance effect is achieved, automobile ornaments with some special functions will not be damaged after being cleaned, and human damage caused by cleaning agent residues is avoided.

Owner:CHONGQING ZHANSHI MACHINERY MFG CO LTD

Automobile engine detergent

InactiveCN106995754ARaise the ratioSimple production processInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSucroseLinear alkylbenzene

The application discloses a car engine cleaning agent, which comprises, in parts by weight, 55 parts of octylphenol polyoxyethylene ether, 62 parts of calcium sorbate, 44 parts of dichloromethane, 73 parts of linear alkylbenzene sulfonic acid, ethanol 23 parts, 33 parts of river sand, 21 parts of sucrose fatty acid ester, 34 parts of hydrogen chloride, 20 parts of trichlorethylene, 27 parts of borax, 32 parts of sodium alkylbenzene sulfonate. Therefore, the proportion of cleaning agent is simple, the production process is simple, the cleaning effect is good, the glossiness after cleaning is high, and the production cost is low.

Owner:孙霞

Corrosion-resistant and waterproof water-based paint

InactiveCN107325695ANot easy to ageProtection strengthFireproof paintsAntifouling/underwater paintsWater basedFiber

The invention discloses corrosion-resistant and waterproof water-based paint which is prepared from the raw materials in parts by weight: 20 to 30 parts of epoxy resin, 60 to 80 parts of saturated linear polyester resin, 1 to 2 parts of pine tar, 15 to 25 parts of polyethylene wax, 1.2 to 2 parts of sodium dodecyl benzene sulfonate, 10 to 15 parts of glycol, 0.8 to 1.4 parts of calcium sorbate, 1 to 2 parts of rosin resin, 2 to 4 parts of thickener, 2 to 4 parts of cross-linking agent, 2 to 4 parts of pigment, 70 to 80 parts of filler and 40 to 60 parts of water. A wood fiber compound is prepared by the following technologies of adding water into soya flour; performing glue milling treatment; adding the polyethylene wax; warming and stirring; adding wood fiber, tung maleic anhydride methyl ester and dimethyl formamide and mixing; warming under a stirring state; continuing stirring; cooling to room temperature; filtering; washing solid by acetone; drying and smashing to obtain the wood fiber compound.

Owner:TIANCHANG JULONG TRAVEL PAINT

Food detergent

InactiveCN102492578AEffective flushingPrevent hard retentionOrganic non-surface-active detergent compositionsSodium acetateFlavor

The invention relates to a food detergent, which is composed of the following components and parts by weight: 5 of the soy extract, carboxymethyl cellulose, polyving akohol, sodium acetate, calcium sorbate, coloring matters, spice and water. The soy extract is clear and transparent solution prepared by enabling soy to be suspended through salt or sodium sulfate solution after being dried, then centrifugally separated, precipitated, filtered and carried out other process. The detergent is made by the following steps: S1 enabling the water and the polyethylene to be added in a dissolving tank, temperature rises and the polyving akohol solution to be dissolved by continuously mixing; and S2 enabling the dissolved polyving akohol solution to be cooled, and enabling the carboxymethyl cellulose, the sodium acetate, the calcium sorbate and the soy extract to be added in order and completely dissolved by continuously mixing. The food detergent can effectively wash residues on foods, soften water simultaneously by adding metal chelant, prevent stereoplasm compositions in the water from remaining on foods.

Owner:汕头市乾力知识产权代理有限公司

Preparation method of chopped pepper preservative

InactiveCN107080143ALong-term hotnessLong-term color retentionClimate change adaptationFood preservationAdditive ingredientNervonic acid

A technical scheme is realized as follows: a product is prepared by organically mixing plant essential oil, nisin, an extract product of Silybum marianum, carboxymethyl chitosan, reuterin, zeaxanthin, calcium sorbate, calcium acetate, nervonic acid, chitin, butyric acid, potassium sorbate, and water with scientific compatibility; the product is especially researched for fresh-keeping of chopped peppers, and is compounded by a plurality of salt-tolerant lactic acid bacteria, and lactic acid bacteria are fermented and produce acid for inhibiting competitors and spoilage bacteria, so that a preparation method of a chopped pepper preservative for long-term keeping of pungency degree, color, local flavor and nutritional components of the chopped peppers is provided.

Owner:HUNAN YIKE BIOLOGICAL ENG CO LTD

Antibacterial food packaging material having large toughness and preparation method thereof

The invention discloses an antibacterial food packaging material having large toughness. The antibacterial food packaging material is prepared from, by weight, 100 parts of low-density polyethylene, 2.3-2.6 parts of nano zinc oxide, 5.6-6.2 parts of oregano vulgare essential oil, 1-3 parts of attapulgite, 12-14 parts of Java cotton, 2-4 parts of maltitol, 5.7-5.9 parts of 3-amino propyl triethoxy silane, 0.7-0.9 part of calcium sorbate, 1.1-1.4 parts of barium sulfate, 0.4-0.6 part of sodium citrate and a proper amount of water. The antibacterial food packaging material uses the low-density polyethylene as a basic material, uses the nano zinc oxide subjected to silane coupling agent activating treatment as a photocatalytic antibacterial agent, and the oregano vulgare essential oil is compounded. Even under the nonluminous condition, the antibacterial food packaging material still has stronger antibacterial properties and wide antibacterial spectrum. In addition, the added modified attapulgite serves as a packing, the adsorbability is strong, the prepared antibacterial food packaging material has large toughness, the antibacterial substances have a certain volatility, and the expiration date and shelf life of foods can be prolonged.

Owner:FUYANG XINRONG FOOD CO LTD

Anticrack adhesive mortar

The invention relates to anticrack adhesive mortar. The mortar is characterized in that the mortar is prepared by mixing, by weight, 18-26 parts of hydrophobic fumed silica, 10-15 parts of zeolite powder, 6-12 parts of ore slag micropowder, 4.5-6.5 parts of 2-phosphonobutane-1,2,4-tricarboxylic acid, 9-18 parts of zinc oxide powder, 20-30 parts of an AF-2 type high-efficiency water reducer, 5-10 parts of a material named as Chinese characters 'Heyesu' by the inventor, 10-15 parts of aluminum potassium sulfate, 5-10 parts of tall oil-pitch sodium sulfonate, 8-16 parts of poly(methyltriethoxysilane), 3-5 parts of calcium sorbate, 2.5-4.5 parts of dicyclohexylammonium nitrite, 3-5 parts of ethoxylated wool fat and 4-7 parts of an auxiliary agent; freezing resistance, carbonization resistanceand wear resistance of the mortar are superior to those of other cement; compared with present formulae, the zinc oxide powder is added into the formula and neutralizes with water, acid and alkali compounds in an initial set process of the adhesive mortar, hydrogen and oxygen are gradually separated, and form a gas; the gas is discharged from the mortar and takes away a part of heat of hydration;and shrinkage cracks caused by temperature changes are reduced.

Owner:不二新材料科技有限公司

Method for preparing D-calcium erythorbate

InactiveCN102372686AQuality improvementMild reaction conditionsOrganic chemistrySlurryAraboascorbic Acid

The invention discloses a method for preparing D-calcium erythorbate by taking D-erythorbic acid as a raw material. The method comprises the following steps of: dissolving D-erythorbic acid into water, and neutralizing D-erythorbic acid by adopting CaCO3, CaO or Ca(OH)2 which is 0.4-0.5 time the molar weight of the D-erythorbic acid, wherein the reacting temperature is at 5-6 DEG C; filtering and removing insoluble impurities from a neutralizing liquid, and concentrating a filtrate to slurry state under reduced pressure; and adding absolute methanol or absolute ethanol into slurry till the volume of the absolute methanol or absolute ethanol accounts for over 90 percent of the total volume of the mixed solution, slowly stirring till crystals are separated out, filtering to obtain wet D-calcium erythorbate, and drying to obtain finished D-calcium erythorbate. The yield of the D-calcium erythorbate prepared with the method is over 83 percent, and the purity is over 98 percent.

Owner:江西省德兴市百勤异VC钠有限公司 +1

Industrial salt

Owner:孙福春

Akebia trifoliata pressed candy and preparation method thereof

PendingCN107156407ASoothing the liver and invigorating the spleenHas stomach smoothnessConfectionerySweetmeatsCross-linkDocosahexaenoic acid

The invention belongs to the technical field of food, and particularly relates to an akebia trifoliata pressed candy and a preparation method thereof. The akebia trifoliata pressed candy comprises akebia trifoliata hydrolysate, D-calcium pantothenate, beta-carotene, seaweed meal, docosahexaenoic acid, calcium saccharin, rose crimson glory flower concrete, calcium sorbate, rutin, pregelatinized starch, hydroxypropyl methylcellulose, cross-linked polyvinylpyrrolidone, magnesium stearate, purified water and ethyl alcohol. Molecular proteins in akebia trifoliata pulps are decomposed into micro-molecular amino acid in the hydrolyzing process of akebia trifoliata, absorption of human bodies is facilitated, components harmful to the human bodies are not introduced in the hydrolyzing process of the akebia trifoliata, spray drying of hydrolysate is directly performed, and beneficial components in the akebia trifoliata pulps are furthest retained.

Owner:HUNAN UNIV OF ARTS & SCI

Coupling agent

InactiveCN108610649AStable chemical propertiesNot easy to decomposeOther chemical processesVinyl etherCarboxylic acid

A coupling agent comprises the following components: 12-34% of acrylic acid ammonia, 12-16% of acrylic acid, 8-10% of ethanol, 3-6% of aluminum oxide, 1.8-2.3% of triethanolamine salt of pyrrolidone carboxylic acid, 3-9% of sodium benzoate, 0.9-1.6% of chondroitin sulfate, 30-32% of mineral water, 5-8% of pigskin, 3-8% of poria cocos powder, 5-14% of seven-up, 6-10% of lotus leaves. 18-22% of starch, 0.7-3.8% of collagen hydrolysate, 7-21% of choline, 1-4% of graphite, 2-9% of castor oil, 8-12% of peanut oil, 2-4% of calcium sorbate, 4-7% of sunflower seeds, 7-21% of triethanol, 8-21% of ethylvinyl ether, 3-10% of 1, 5, 6-tetrahydrobenzyl alcohol, 12-29% of elderberry, 3-8% of iodized salt, 1-7% of acid latex paint and 4-11% of vanillin. The coupling agent has stable chemical property, and is not easy to decompose under high-temperature and high-pressure environments.

Owner:周宁

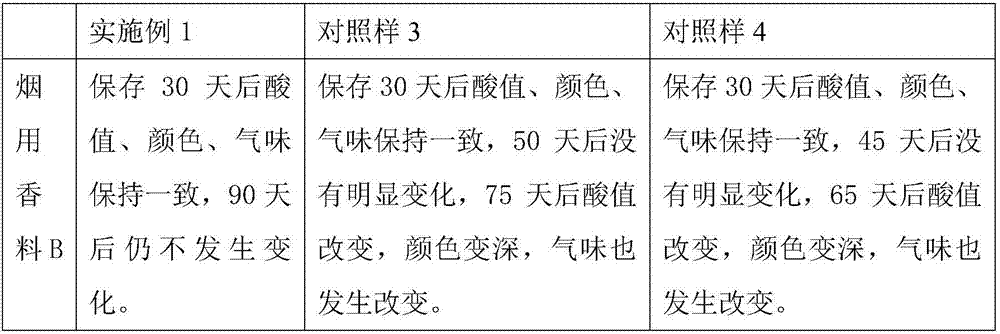

An additive capable of prolonging the shelf life of tobacco flavorings

ActiveCN107455788BGrowth inhibitionExtended shelf lifeTobacco preparationTobacco treatmentFlavorOrganic solvent

The invention provides an additive capable of prolonging the shelf life of tobacco perfumes. The additive contains, by mass, 1-3% of sorbic acid, 3-4% of potassium sorbate, 2-4% of calcium sorbate and 3-8% of squalane, and the solvent of the additive is formed by the combination of water and an organic solvent. By means of the additive, the growth of microorganisms can be effectively inhibited, the shelf life of the tobacco perfumes can be prolonged, the stability of all components in the tobacco perfumes can be improved, and the original fragrance or flavor of the tobacco perfumes is not affected.

Owner:CHINA TOBACCO GUANGDONG IND

Preserved etherified cyclodextrin derivatives containing liquid aqueous pharmaceutical composition

ActiveUS10071162B2Improve solubilityInhibit microbial growthAntibacterial agentsNervous disorderSodium acetateBenzoic acid

Owner:BOEHRINGER LNGELHEIM VETMEDICA GMBH

Additive capable of prolonging shelf life of tobacco perfumes

ActiveCN107455788AGrowth inhibitionExtended shelf lifeTobacco preparationTobacco treatmentFlavorOrganic solvent

The invention provides an additive capable of prolonging the shelf life of tobacco perfumes. The additive contains, by mass, 1-3% of sorbic acid, 3-4% of potassium sorbate, 2-4% of calcium sorbate and 3-8% of squalane, and the solvent of the additive is formed by the combination of water and an organic solvent. By means of the additive, the growth of microorganisms can be effectively inhibited, the shelf life of the tobacco perfumes can be prolonged, the stability of all components in the tobacco perfumes can be improved, and the original fragrance or flavor of the tobacco perfumes is not affected.

Owner:CHINA TOBACCO GUANGDONG IND

An additive for prolonging the shelf life of tobacco flavorings

ActiveCN107365627BGrowth inhibitionExtended shelf lifeTobacco preparationEssential-oils/perfumesBiotechnologyOrganic solvent

The invention provides an additive for prolonging the shelf life of a tobacco flavor. The additive contains the following components in percentage by mass: 3-5% of sorbic acid, 3-5% of potassium sorbate, 3-5% of calcium sorbate and 0.1-1% of nicotine; and a solvent for the additive is a composition of water and an organic solvent. The additive provided by the invention can effectively inhibit the growth of microorganisms, prolong the shelf life of the tobacco flavor and improve the stability of the components of the tobacco flavor. Besides, the additive provided by the invention does not influence the original fragrance or scent of the tobacco flavor.

Owner:CHINA TOBACCO GUANGDONG IND

Low-temperature-brittleness modified acrylonitrile-butadiene-styrene copolymer

The invention discloses a low-temperature-brittleness modified acrylonitrile-butadiene-styrene copolymer. The low-temperature-brittleness modified acrylonitrile-butadiene-styrene copolymer is preparedfrom the raw materials of, in parts by weight, 100-140 parts of acrylonitrile-butadiene-styrene copolymers, 40-60 parts of polytetrafluoroethylene, 4-6 parts of di-tert-butyl hydrogen peroxide, 1-2 parts of 2,4,6-tri(dimethylamine)phenol, 2.5-4.5 parts of silane coupling agents KH-570, 15-25 parts of hollow glass beads, 10-18 parts of vermiculite powder, 6-12 parts of mica powder, 12-20 parts ofprecipitated barium sulphate, 10-18 parts of polyurethane rubber, 4-8 parts of calcium sorbate and 4-8 parts of sodium dodecyl benzene sulfonate. The low-temperature-brittleness modified acrylonitrile-butadiene-styrene copolymer is good in low temperature brittleness, good in anti-aging effect, high in structural strength and high in anti-impact strength, and is suitable for parts in the field ofautomobiles.

Owner:QUANJIAO XIANGRUI PLASTIC

Printing ink cleaning agent and preparation method thereof

ActiveCN103525168BImprove craftsmanshipReduce pollutionChemical paints/ink removersSide effectPolyethylene glycol

The invention discloses a cleaning agent of printing ink. The cleaning agent is characterized by comprising the following materials in parts by weight: 1-3 parts of diethanol amine, 1-2 parts of oxalic acid, 5-10 parts of sodium benzoate, 9-12 parts of propylene glycol, 13-15 parts of alcohol, 6-8 parts of polyethylene glycol, 1-2 parts of coconut fatty acid alkanolamide, 3-5 parts of polysorbate 80, 2-3 parts of calcium sorbate, 1-2 parts of sodium hypochlorite, 10-12 parts of dipropylene glycol mono butyl ether, 4-5 parts of additives and 100-110 parts of water. The cleaning agent disclosed by the invention has the advantages that due to addition of the additives, the processing property of the cleaning agent is improved, and the toxic and side effects and the pollution to environment of the cleaning agent are alleviated; the ink dissolving and diluting capabilities of the cleaning agent are excellent, no toxicity and pollution are caused, the cleaning agent is not flammable and combustible, the damage on rubber rollers of a printing machine is low, the use is convenient and the cost is low.

Owner:HEFEI ALL ROUND POLYMER MATERIAL FACTORY

Waterproof bonding mortar

The invention relates to a waterproof bonding mortar. The waterproof bonding mortar is characterized by being prepared from the following raw materials by weight through mixing: 18 to 26 parts of hydrophobic fumed silica, 10 to 15 parts of calcium stearate, 6 to 12 parts of slag micropowder, 4.5 to 6.6 parts of 2-phosphonobutane-1,2,4-tricarboxylic acid, 9 to 18 parts of zinc oxide powder, 20 to 30 parts of an AF-2 type superplasticizer, 5 to 10 parts of glass fibers, 10 to 15 parts of aluminum potassium sulfate, 5 to 10 parts of tallol oil-asphalt sodium sulfonate, 8 to 16 parts of polymethyltriethoxysilane, 3 to 5 parts of calcium sorbate, 2.5 to 4.5 parts of dicyclohexyl amine nitrite, 3 to 5 parts of ethoxylated lanolin and 4 to 7 parts of an auxiliary agent. The waterproof bonding mortar provided by the invention has better frost resistance, carbonization resistance and wear resistance than other cement. Compared with traditional formulas, zinc oxide powder is added in the formulafor the waterproof bonding mortar; and during initial setting, the bonding mortar is neutralized by water and acidic and alkaline substances, so hydrogen and oxygen are gradually separated and becomegases that are discharged from the bonding mortar, and at the same time, a part of hydration heat is taken away, thereby reducing shrinkage cracks caused by temperature changes.

Owner:不二新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com