Anti-rust cleaning liquid for mechanical processing equipment

A technology of mechanical processing and cleaning liquid, applied in detergent compositions, soap detergent compositions, surface active non-soap compounds and cleaning compositions, etc., can solve the problems of unfavorable production and single performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

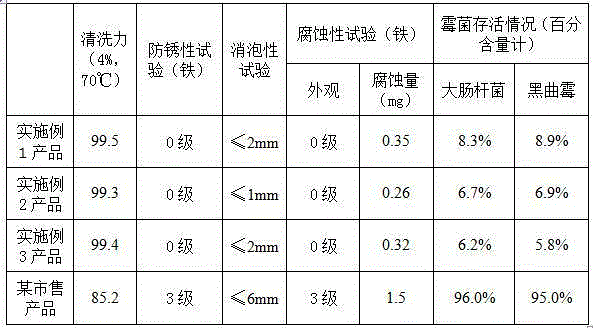

Examples

Embodiment 1

[0040] The antirust cleaning solution for mechanical processing equipment in this embodiment is composed of the following components in parts by mass: 50 parts of trisodium phosphate, 52 parts of ethoxylated amine, 48 parts of octylphenol polyoxyethylene ether, and 52 parts of citric acid , 48 parts of ethylene glycol butyl ether, 52 parts of benzyltriphenylphosphine bromide, 48 parts of malic acid, 54 parts of difluorodichloromethane, 48 parts of benzotriazole, 52 parts of calcium sorbate, caprylic acid 48 parts of glycerides, 52 parts of oxalic acid, 48 parts of hard resin monoglyceride, 52 parts of carboxyacetic acid, 48 parts of biochemical fulvic acid, 52 parts of sodium molybdate, 48 parts of tricresyl phosphate, 52 parts of sodium tripolyphosphate, 48 parts of sodium nitrite, 52 parts of zinc epoxy acid, 48 parts of morpholine, 52 parts of petroleum sulfonate, 48 parts of chlorothalonil, and 1000 parts of water.

[0041] The steps of the preparation method of the above-...

Embodiment 2

[0046] The antirust cleaning solution for mechanical processing equipment in this embodiment is composed of the following components in parts by mass: 52 parts of trisodium phosphate, 54 parts of ethoxylated amine, 50 parts of octylphenol polyoxyethylene ether, and 54 parts of citric acid , 50 parts of ethylene glycol butyl ether, 54 parts of benzyl triphenylphosphine bromide, 50 parts of malic acid, 56 parts of difluorodichloromethane, 50 parts of benzotriazole, 54 parts of calcium sorbate, caprylic acid 50 parts of glycerides, 54 parts of oxalic acid, 50 parts of stearic acid monoglyceride, 54 parts of carboxyacetic acid, 50 parts of biochemical fulvic acid, 54 parts of sodium molybdate, 50 parts of tricresyl phosphate, 54 parts of sodium tripolyphosphate, 50 parts of sodium nitrite, 54 parts of zinc epoxy acid, 50 parts of morpholine, 54 parts of petroleum sulfonate, 50 parts of chlorothalonil, and 1500 parts of water.

[0047] The steps of the preparation method of the abo...

Embodiment 3

[0052] The antirust cleaning solution for mechanical processing equipment in this embodiment is composed of the following components in parts by mass: 54 parts of trisodium phosphate, 56 parts of ethoxylated amine, 52 parts of octylphenol polyoxyethylene ether, and 56 parts of citric acid , 52 parts of ethylene glycol butyl ether, 56 parts of benzyltriphenylphosphine bromide, 52 parts of malic acid, 58 parts of difluorodichloromethane, 52 parts of benzotriazole, 56 parts of calcium sorbate, caprylic acid 52 parts of glycerides, 56 parts of oxalic acid, 52 parts of stearic acid monoglyceride, 56 parts of carboxyacetic acid, 52 parts of biochemical fulvic acid, 56 parts of sodium molybdate, 52 parts of tricresyl phosphate, 56 parts of sodium tripolyphosphate, 52 parts of sodium nitrite, 56 parts of zinc epoxy acid, 52 parts of morpholine, 56 parts of petroleum sulfonate, 52 parts of chlorothalonil, and 2000 parts of water.

[0053] The steps of the preparation method of the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com