Additive for prolonging shelf life of tobacco flavor

A technology of tobacco spices and additives, which is applied in the direction of essential oils/flavors, tobacco, applications, etc., can solve the problems of long transportation time, short shelf life of tobacco flavors, and deterioration of tobacco flavors, so as to extend the shelf life, inhibit microbial growth, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

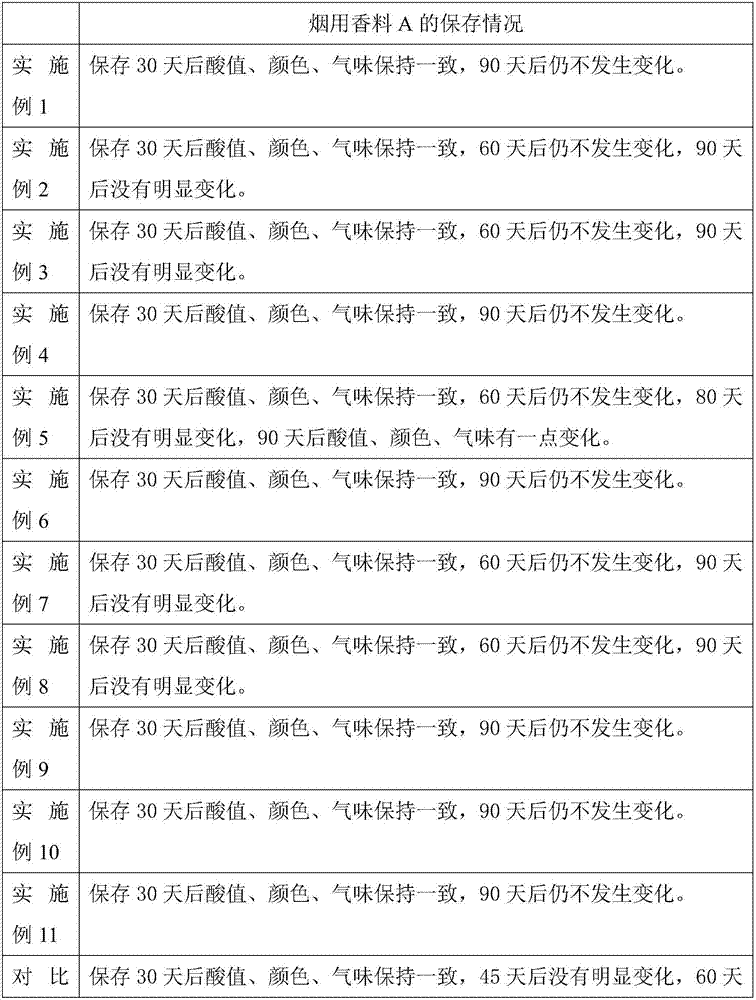

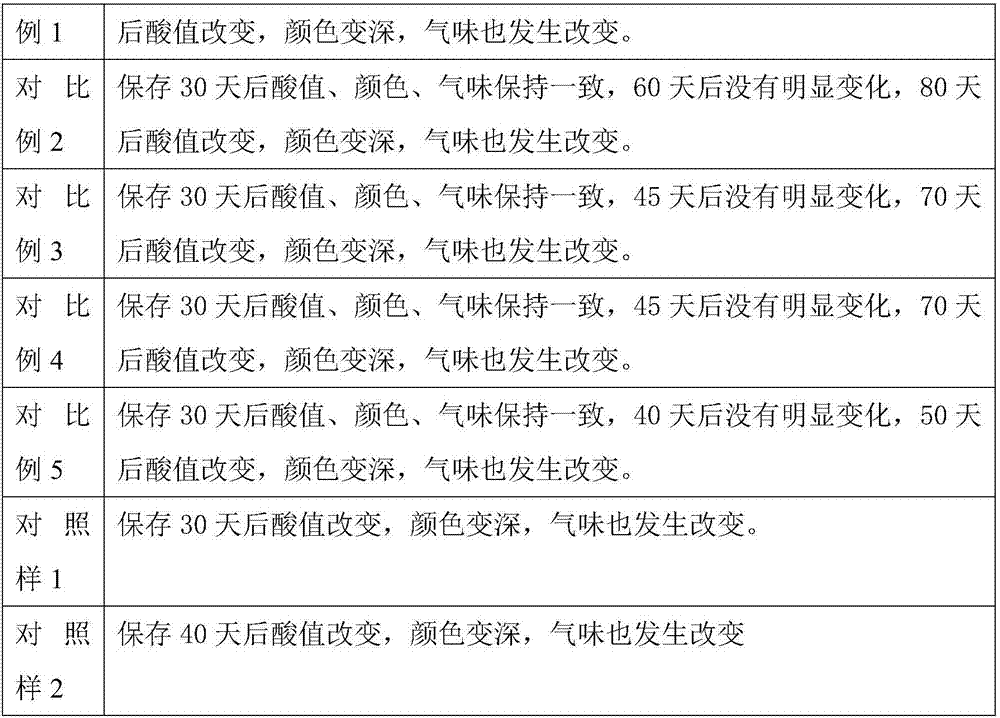

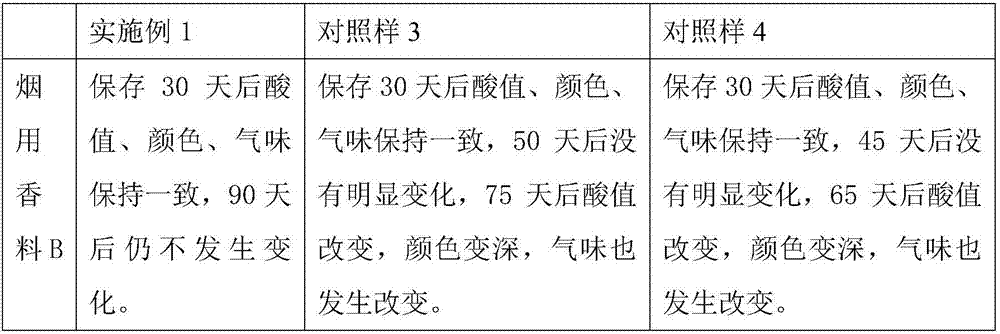

Examples

Embodiment 1

[0021] An additive for prolonging the shelf life of tobacco spices, the additive contains 4% sorbic acid, 4% potassium sorbate, 4% calcium sorbate, and 0.8% nicotine in a mass percentage, and the solvent of the additive is water and ethanol The combination of the mass dosage of ethanol and the mass dosage ratio of water is 0.3:1.

[0022] The ratio of the sum of the mass of potassium sorbate and calcium sorbate to the mass of sorbic acid is 2:1.

Embodiment 2

[0024] An additive for prolonging the shelf life of tobacco spices. The additive contains 4% by mass of sorbic acid, 3% of potassium sorbate, 5% of calcium sorbate, and 0.8% of nicotine. The solvent of the additive is water and ethanol The combination of the mass dosage of ethanol and the mass dosage ratio of water is 0.3:1.

[0025] The ratio of the sum of the mass of potassium sorbate and calcium sorbate to the mass of sorbic acid is 2:1.

Embodiment 3

[0027] An additive for prolonging the shelf life of tobacco spices, the additive contains 5% by mass of sorbic acid, 5% of potassium sorbate, 3% of calcium sorbate, and 0.8% of nicotine, and the solvent of the additive is water and ethanol The combination of the mass dosage of ethanol and the mass dosage ratio of water is 0.3:1.

[0028] The ratio of the mass sum of potassium sorbate and calcium sorbate to the mass of sorbic acid is 1.6:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com