Polyformaldehyde masterbatch with double-function of toughening and coloring, and preparation method thereof

A polyoxymethylene, dual-function technology, applied in the field of polyoxymethylene masterbatch and preparation, to achieve the effects of improving notched impact strength, reducing strength and rigidity, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

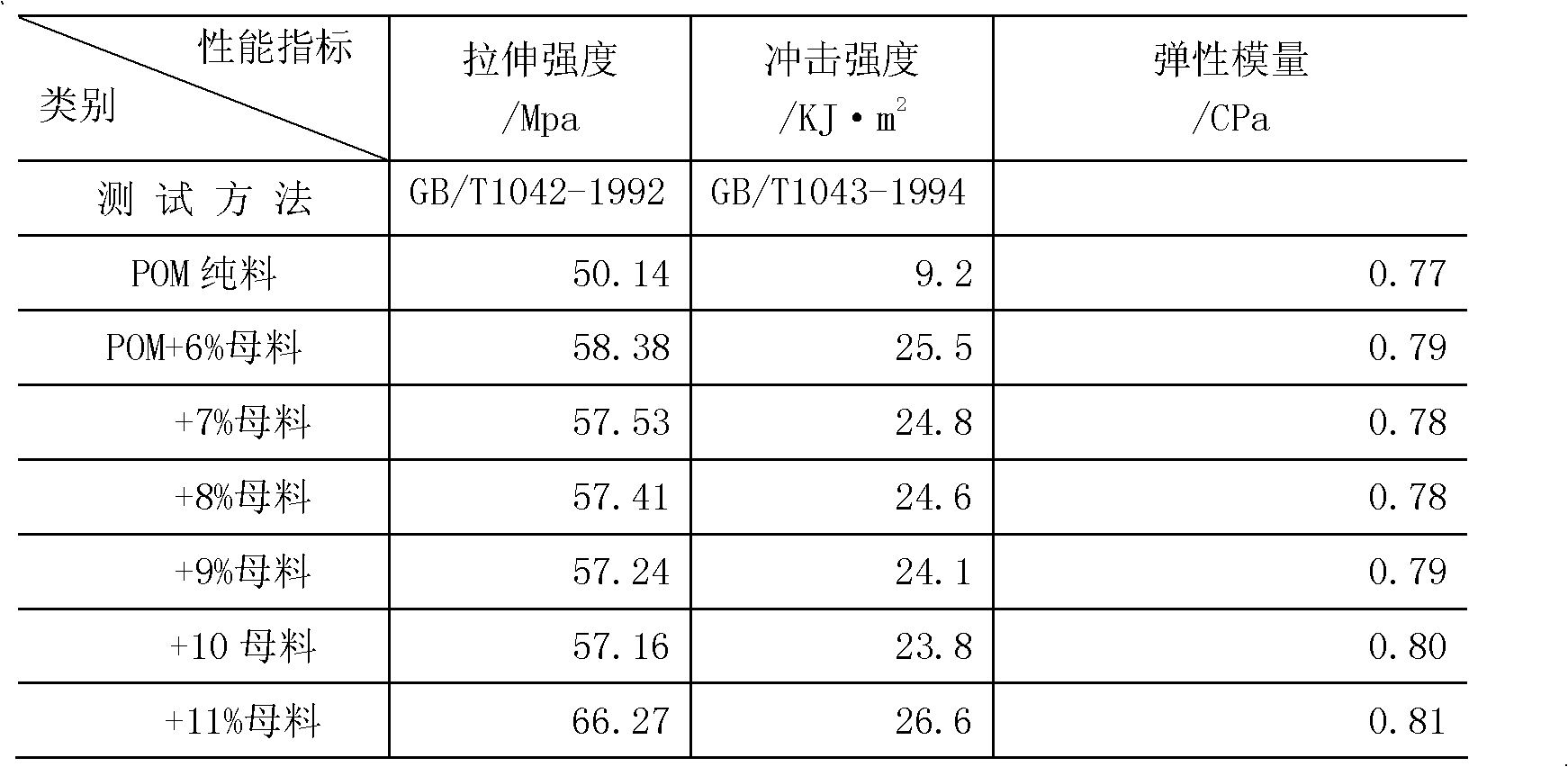

Method used

Image

Examples

Embodiment Construction

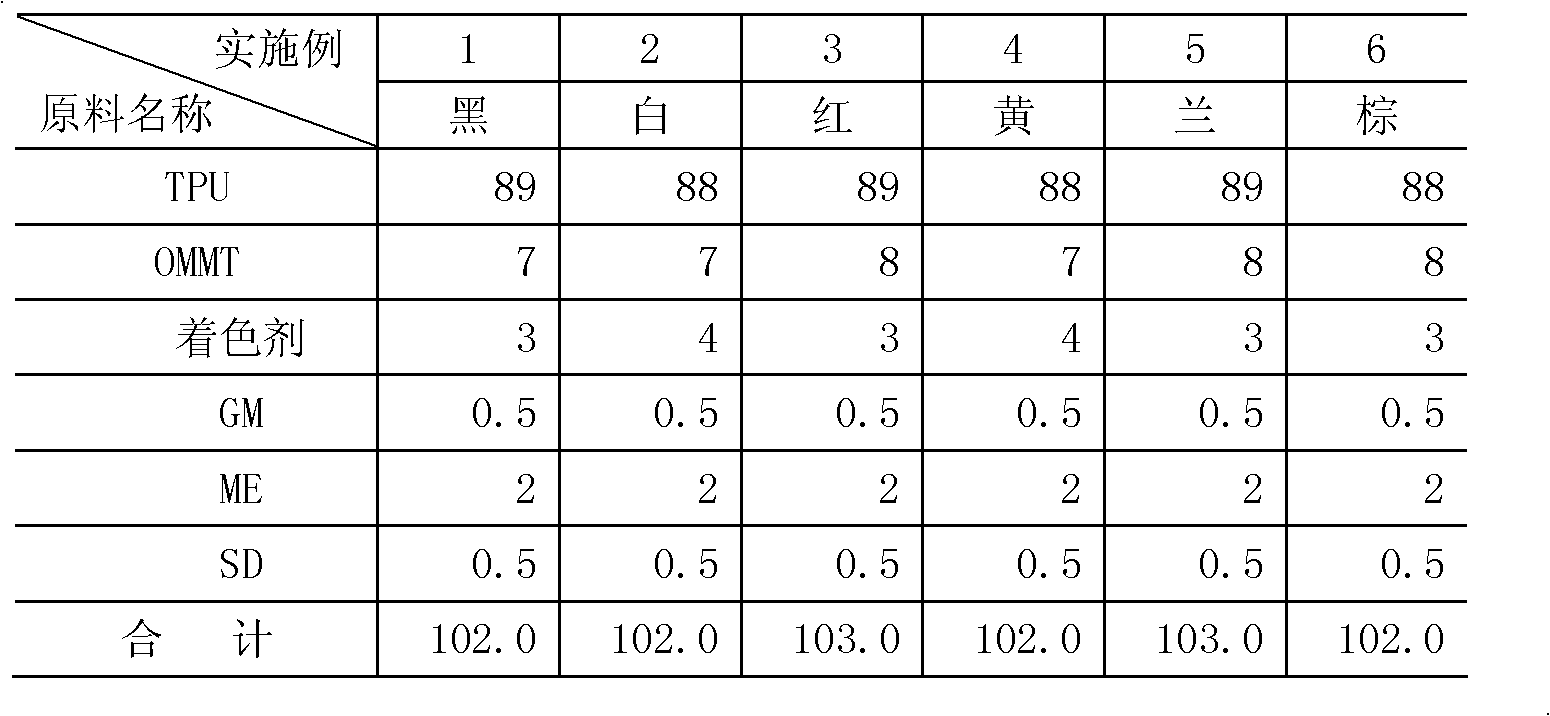

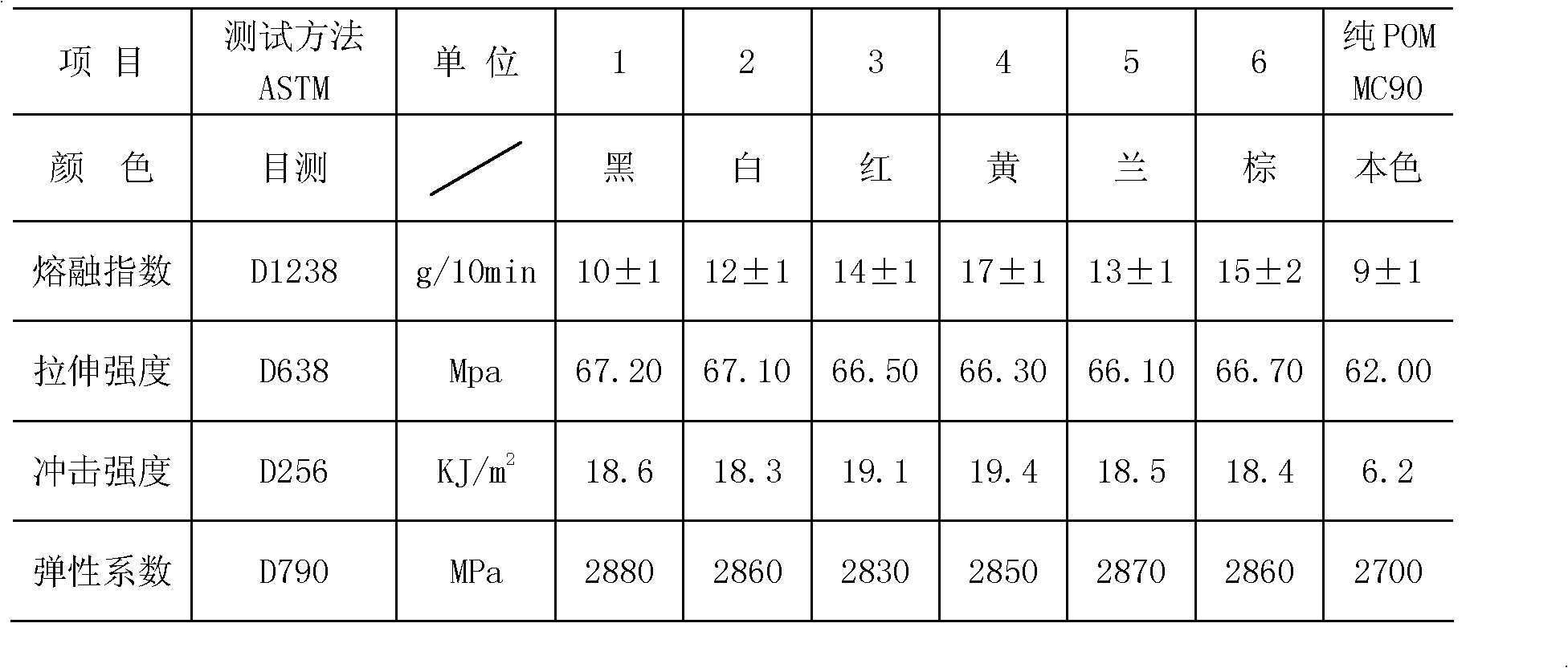

[0029] The five embodiments of the present invention described in Table 2 below use polyether polyurethane elastomer as the main toughening agent, and nano-level layered silicates and nano-level inorganic pigments are pigment carbon black (1) and rutile titanium. White powder (2), cadmium red (3), titanium yellow (4), cobalt blue (5), iron brown (6) are toughening agents and coloring agents, polysiloxane is lubricating dispersing and release agent, and melamine is absorbent Aldehydes, phenylethyl phenol and diphenyl-p-phenylenediamine are acid absorbents and heat stabilizers, but the examples should not be interpreted as limiting the scope of the present invention.

[0030] Table 2 Example formula

[0031]

[0032] The preparation steps of the foregoing embodiment are as follows:

[0033] 1. The raw materials determined in the formula of the embodiment are properly measured according to the proportion, put into a high-speed mixer, firstly mix at low speed for 5 minutes, then turn to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com