Multi-dimensional ultrasonic ELID grinding machining device for inner raceway of bearing

A technology of grinding and inner raceway, which is applied in the direction of grinding workpiece support, abrasive surface adjustment device, metal processing equipment, etc., can solve the problem of inability to realize the enhanced fatigue life of bearing inner and outer ring raceways, reduce the manufacturing cost of high-precision bearings, The strengthening layer loses its strengthening effect and other problems, and achieves the effects of saving machining tool change time, improving machining accuracy and machining quality, and improving machining efficiency and machining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

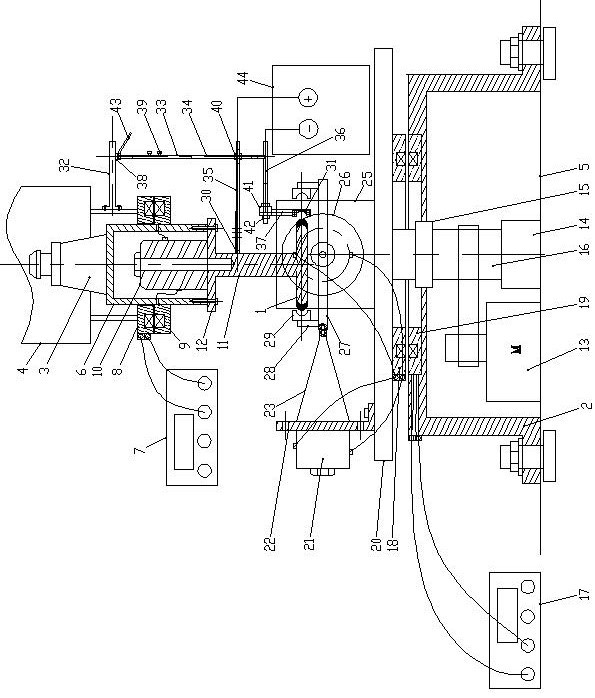

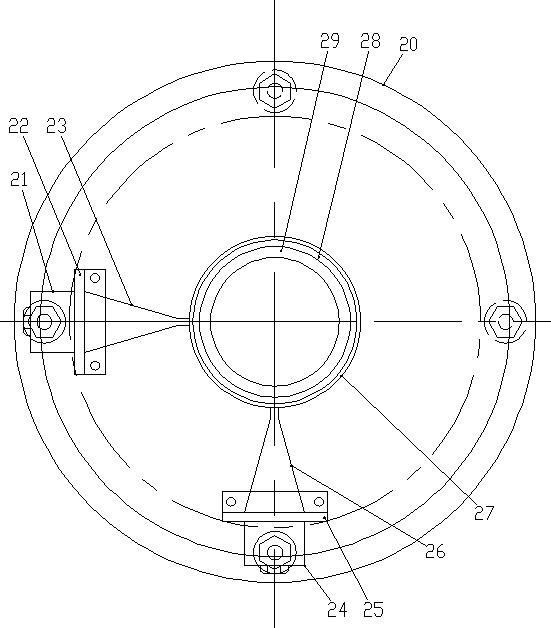

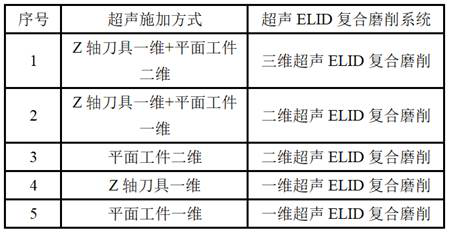

[0024] like figure 1 and figure 2 As shown, a multi-dimensional ultrasonic ELID grinding bearing inner raceway device of the present invention includes a tool ultrasonic part, an ELID trimming part, a workpiece ultrasonic part, a workpiece clamping part and a forming grinding wheel 1; The machine tool spindle 4 is connected, the machine tool spindle 4 is arranged vertically downward, and the forming grinding wheel 1 is fixed at the lower end of the ultrasonic part of the tool to realize additional ultrasonic vibration on the forming grinding wheel 1; the two electrodes of the ELID dressing part are respectively connected with the center of the forming grinding wheel 1 and The circumferential edge is electrically connected to realize the on-line electrolytic dressing of the forming grinding wheel 1; the ultrasonic part of the workpiece is fixed on the machine table 5, and the workpiece clamping part is arranged on the ultrasonic part of the workpiece to realize the addition of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com