Light and small elevating quick assembling and disassembling rice and wheat harvester

A wheat harvester, light and small technology, applied in the field of wheat harvester and light rice, can solve the problems of stuck cutting surface, easy to enter the moving blade, small size, etc., to prevent machine damage accidents, high work efficiency, easy to use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

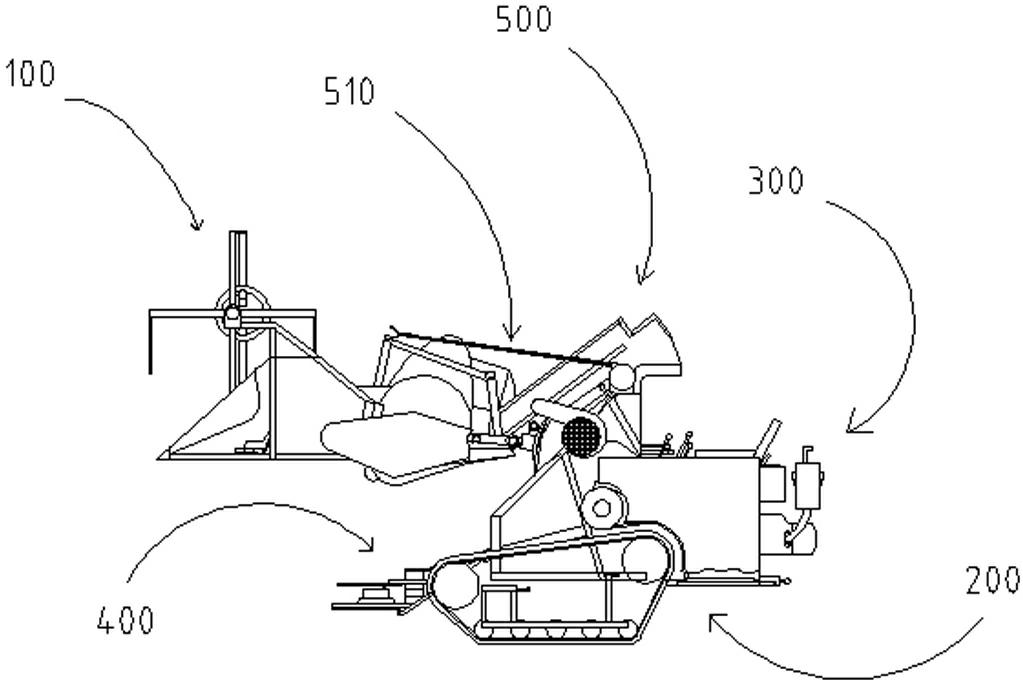

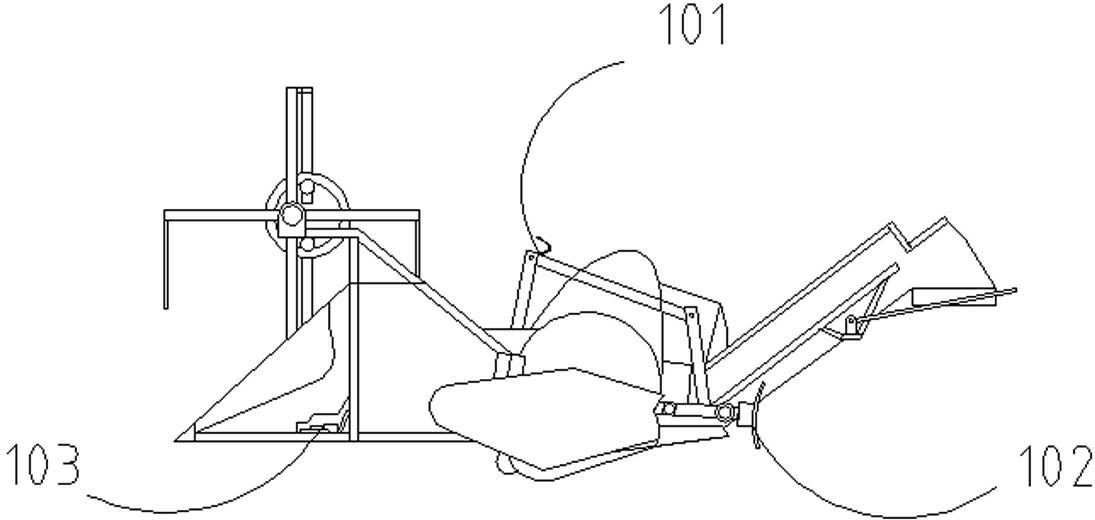

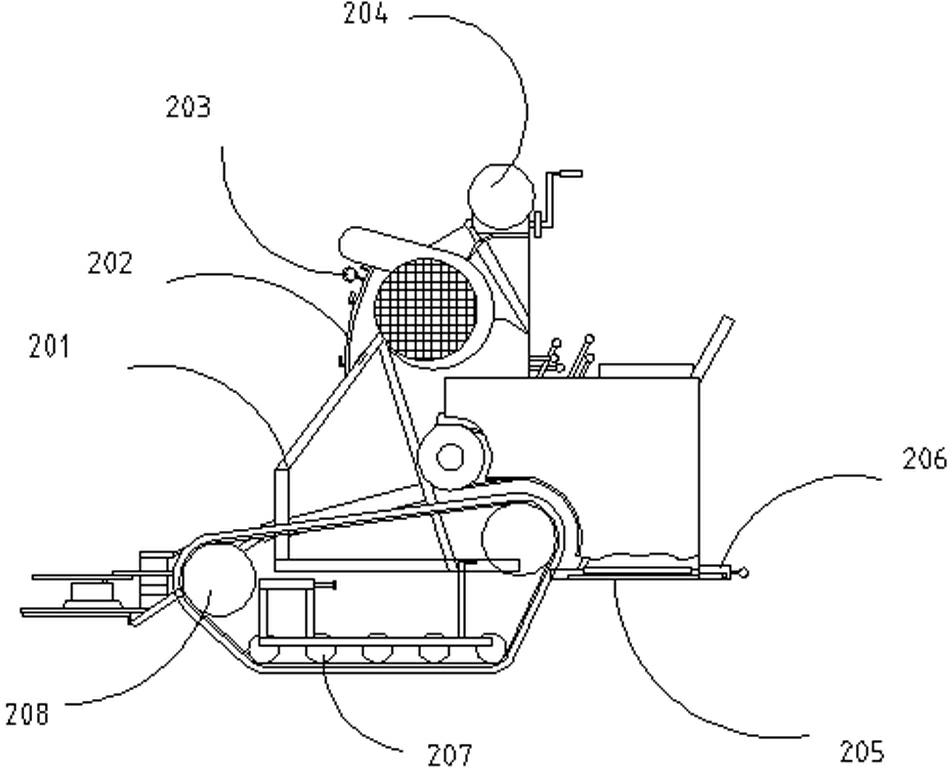

[0019] Specific implementation methods: 1. See figure 1 , figure 2 , as a preferred embodiment of the present invention, a light and small quick disassembly, loadable light and small rice and wheat rice harvester consists of a harvesting assembly 100, a chassis assembly 200, a power assembly 300, and a cutting knife The row assembly 400 and the blower assembly 500 are composed. The ear outlet of the cutting platform is directly connected with the ear inlet of the threshing barrel to form an overall harvesting assembly 100; the orange bar knife row assembly 400 is located at the front end of the chassis assembly 200; The front upper end of the chassis assembly 200 is provided with an embedded socket assembly 202; the rear lower part of the frame of the chassis assembly 200 is provided with a slot and a tensioner 206; the top of the chassis assembly 200 is provided with a pull rope 204; the lower part of the power assembly 300 is provided with a flashboard 302; the moving kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com