Cutting edge structure, manufacturing method of cutting edge and kitchen knife

A manufacturing method and blade technology, applied in metal material coating technology, metal processing, coating, etc., can solve the problems that kitchen knives cannot have high wear resistance, high cutting performance, high toughness, and high hardness at the same time, and achieve long-lasting Maintains sharpness, high cutting performance, and improves wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

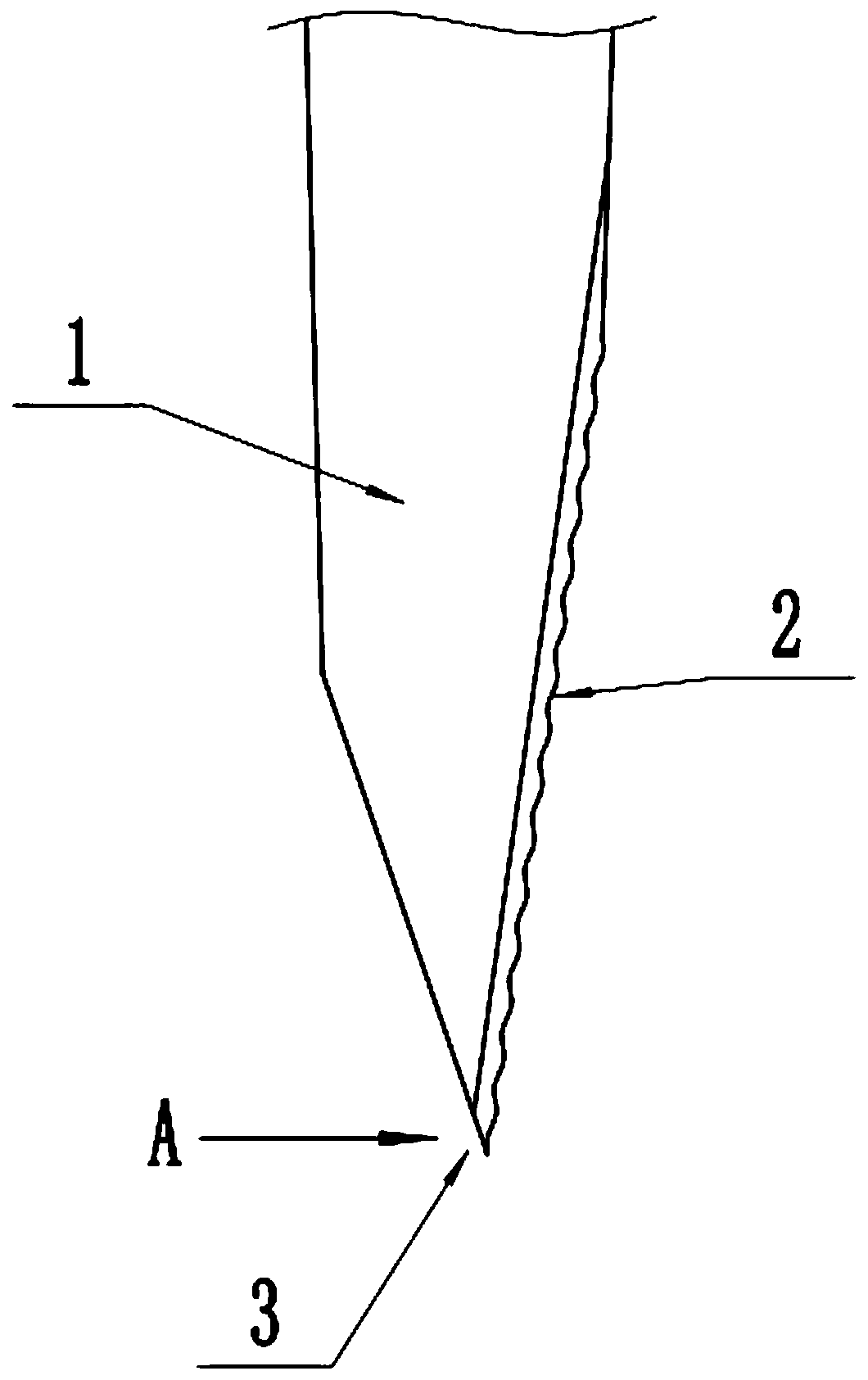

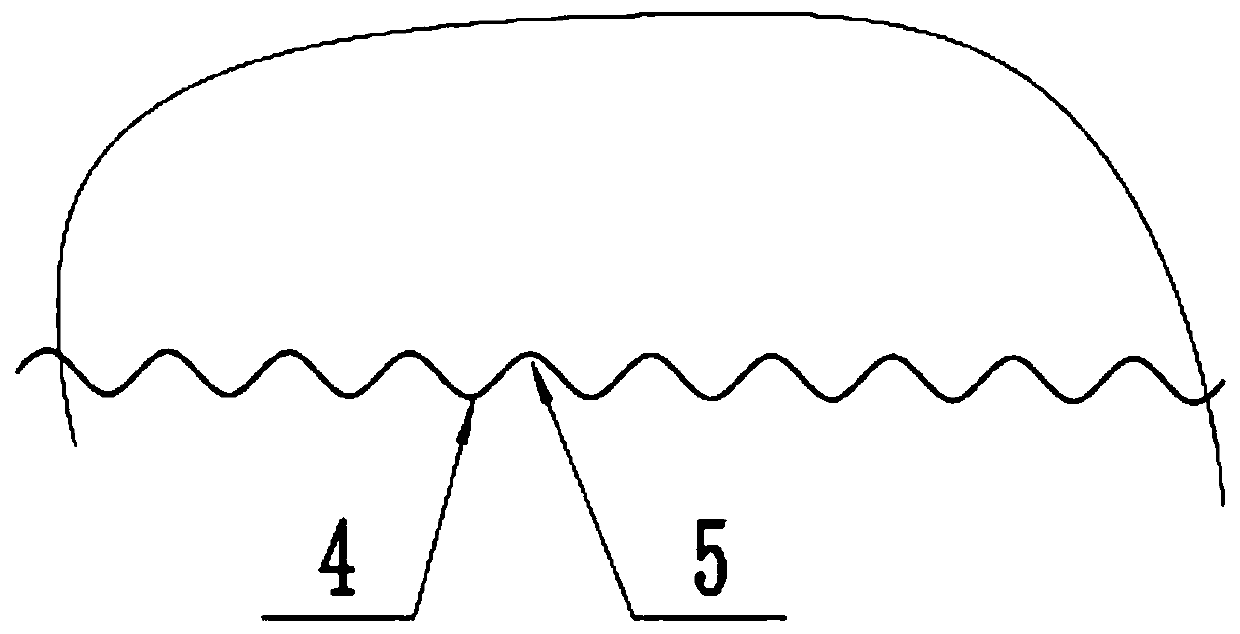

[0032] Such as figure 1 and 2 As shown, Embodiment 1 provides a blade structure, which includes a knife body 1 and a composite material layer 2, and the composite material layer 2 is arranged on one side of the knife body 1, that is, the composite material layer 2 and the knife body 1 are laminated or In the laminated structure, the composite material layer 2 and the knife body 1 form an integrated structure through three times of high-temperature fusion, the surface of the composite material layer 2 is uneven and concave-convex, and the thickness of the composite material layer 2 is 20-30 microns.

[0033] Through the composite material fusion process, the knife body 1 and the composite material layer 2 are fused together to form a very strong fusion layer. This fusion layer with composite materials has extremely high hardness and wear resistance. Due to the composite The material layer 2 is laminated with the knife body 1, and the welded layer is always at the cutting edge ...

Embodiment 2

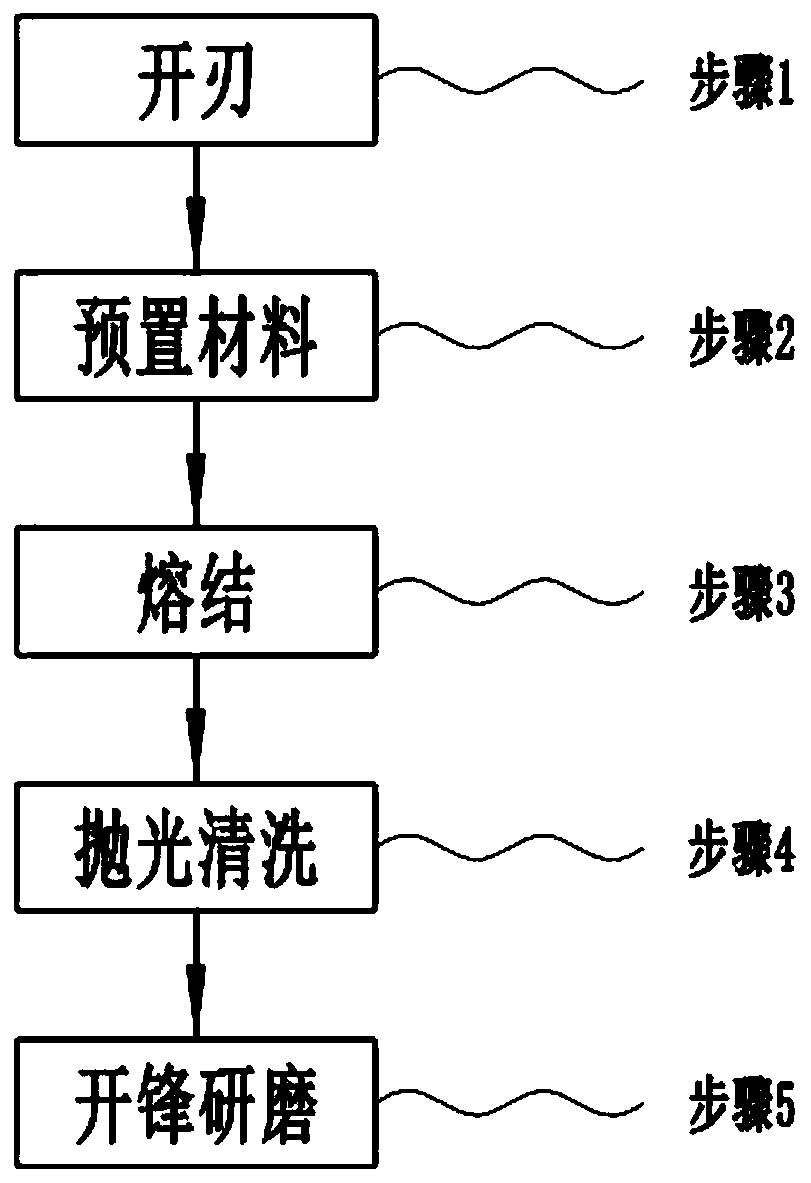

[0040] Such as image 3 As shown, Embodiment 2 provides a method for manufacturing the blade structure, which is used to manufacture the blade structure in Embodiment 1. The method includes the following five steps.

[0041] Step 1. Sharpen the blade. For the knife body that has been heat-treated and tempered, a beveled edge with an edge angle of 10-15° is formed on one side of the knife body, so that the beveled edge is 3-5mm, and the beveled edge is used as a fusion surface, and the other side is It can be sharpened according to the conventional cutting method.

[0042] Step 2. Preset materials. A layer of composite material particles is preset on the slope of the cutting edge, and the thickness of the preset composite material particles is 80-120 microns.

[0043] Step 3, sintering. Use the sintering equipment to sinter the bevel of the cutting edge pre-prepared with composite material particles for three times, which can make the bevel of the cutting edge and the compo...

Embodiment 3

[0050] Embodiment 3 provides a kitchen knife, including a knife body and a knife handle fixed to the knife body, characterized in that a composite material layer is provided on one side of the knife body, and the composite material layer and the knife body are integrated by three times of high-temperature sintering structure, the surface of the composite material layer is uneven and concave-convex, and the thickness of the composite material layer is 20-30 microns.

[0051] Through the composite material fusion process, the knife body and the composite material layer are fused together to form a very strong fusion layer. This fusion layer with composite material has extremely high hardness and wear resistance. Due to the composite material layer It is laminated with the knife body, and the welding layer is always on the cutting edge, so that one side of the knife body at the cutting edge is protected by a composite material layer, which improves the wear resistance of the cutti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com