Intelligent new textile material cutting-off equipment for textile

A technology of cutting equipment and new materials, applied in the textile field, can solve the problems of tearing, reduction of viscose fiber fabric strength and wear resistance, rusting of cutters, etc., and achieve the effect of improving strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

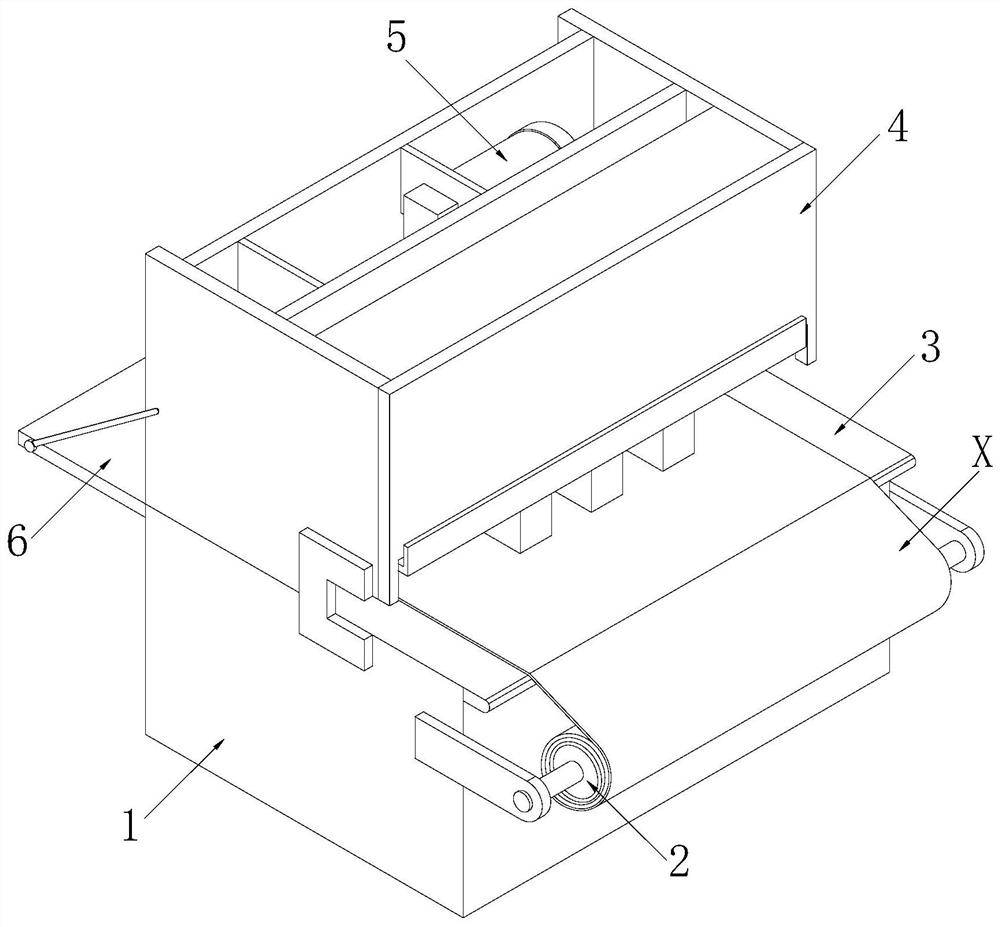

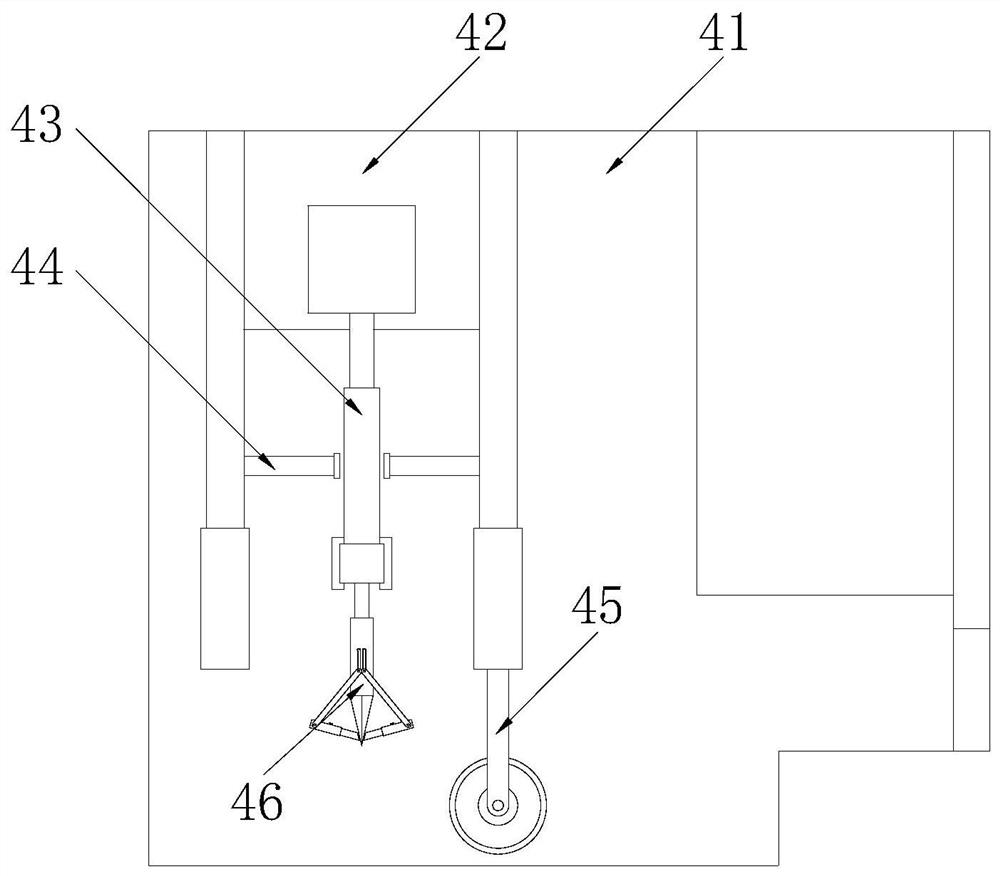

[0022] as attached figure 1 to attach Figure 4 Shown:

[0023] The present invention is an intelligent textile new material cutting device for textiles, the structure of which includes a fixed seat 1, an unwinder 2, a placement table 3, a cutting host 4, a motor 5, and a stacking table 6. The right front end of the fixed seat 1 is provided with a The unwinder 2 is installed on the upper surface of the fixed seat 1 and is located at the lower right end of the placement table 3. The upper end of the fixed seat 1 is fixed to the bottom of the cutting host 4, and the placement table 3 is located below the cutting host 4. The cutting A motor 5 is arranged inside the upper end of the main engine 4, and the stacking platform 6 is located at the left end of the fixed seat 1, and the stacking platform 6 and the placement platform 3 are located on the same water surface, and the cutting main engine 4 includes a main engine box 41, a support plate 42, a propeller 43. Auxiliary plate 4...

Embodiment 2

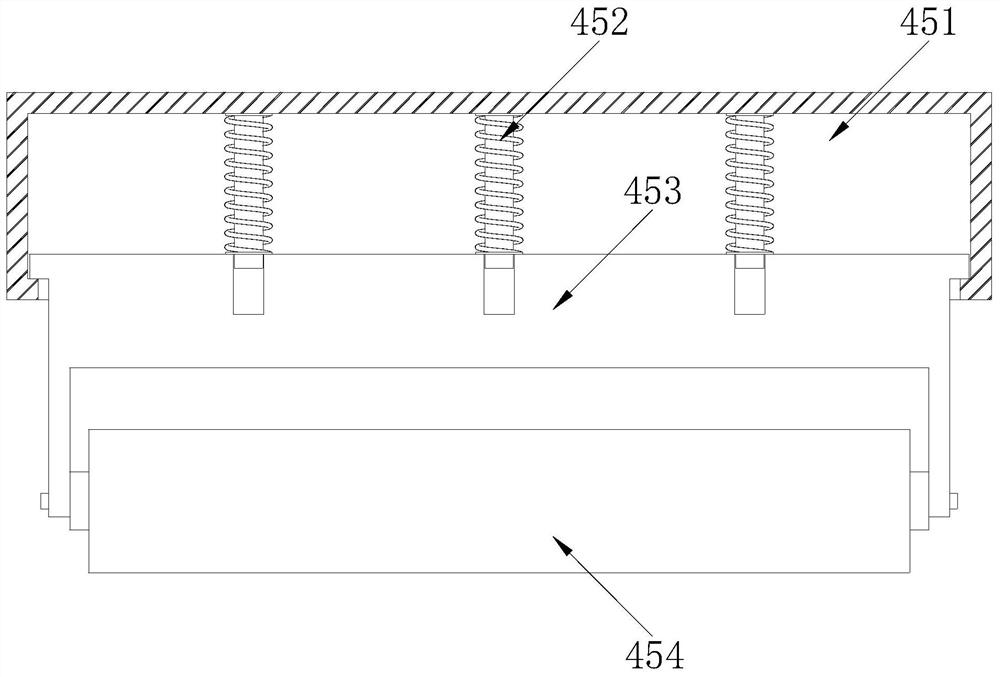

[0029] as attached Figure 5 To attach Figure 7 Shown:

[0030] Wherein, the cutter mechanism 46 includes a support rod 461, a slide rail 462, a flattening mechanism 463, and a cutter 464. The top of the support rod 461 is fixed to the bottom of the propeller 43, and the outer surface of the support rod 461 is embedded with a slide rail 462, and the upper end of the flattening mechanism 463 is slidably installed inside the slide rail 462, the flattening mechanism 463 is located outside the cutter 464, and the top of the cutter 464 is fixed to the bottom of the support rod 461, and the slide rail 462 is provided with Four, and two as a group, are respectively arranged on the front and rear sides of the support rod 461, and two flattening mechanisms 463 are provided, respectively connected with four slide rails 462, to ensure that the two flattening mechanisms 463 The front and rear ends of the four slide rails 462 are smoothly linked, so that the inclined flattening mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com