Rubbish barrel capable of separating rubbish bag

A garbage bag and garbage can technology, applied in the field of garbage cans, can solve problems such as trouble, loss of use value of wet garbage, and addition of fertilizer production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

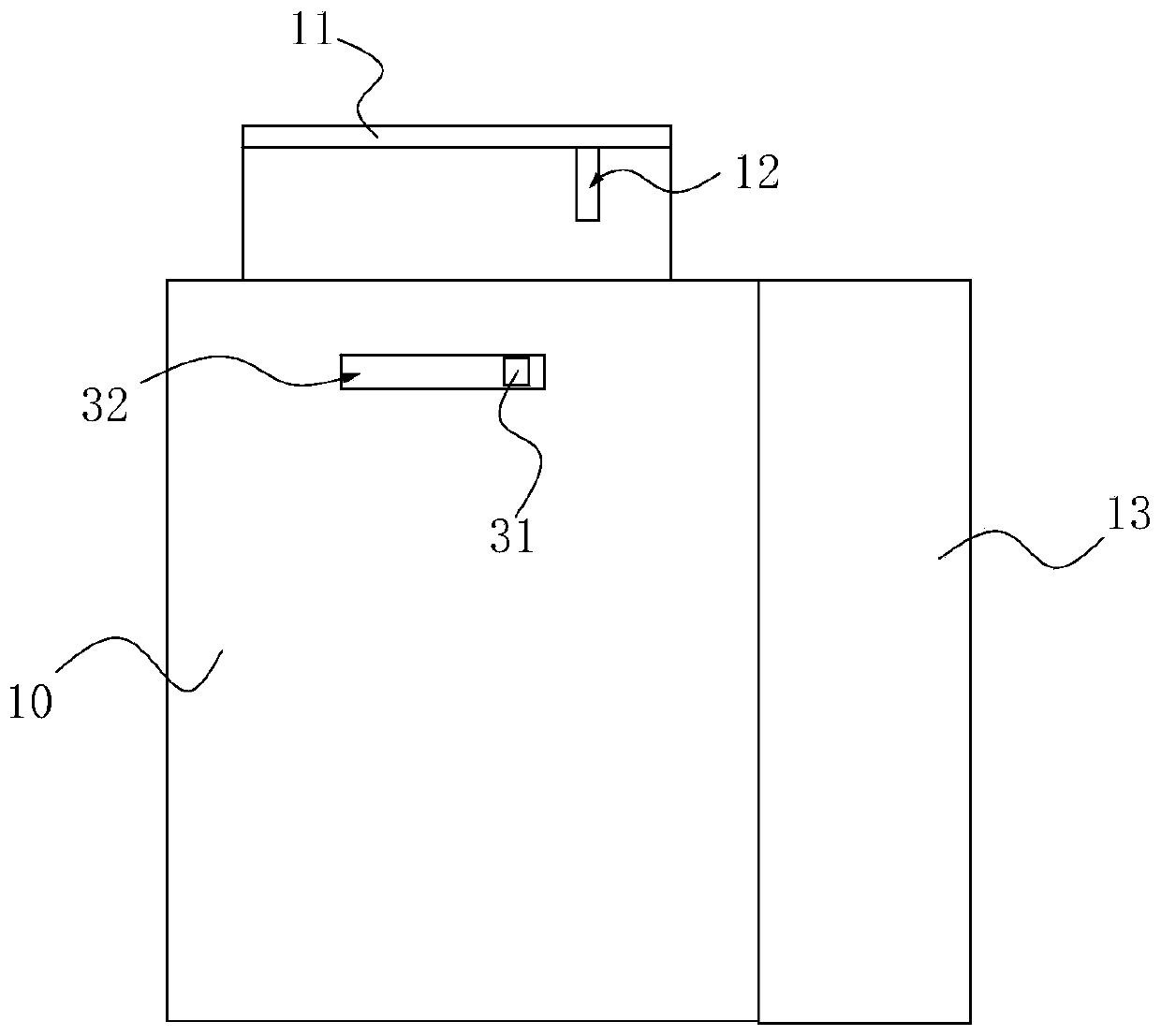

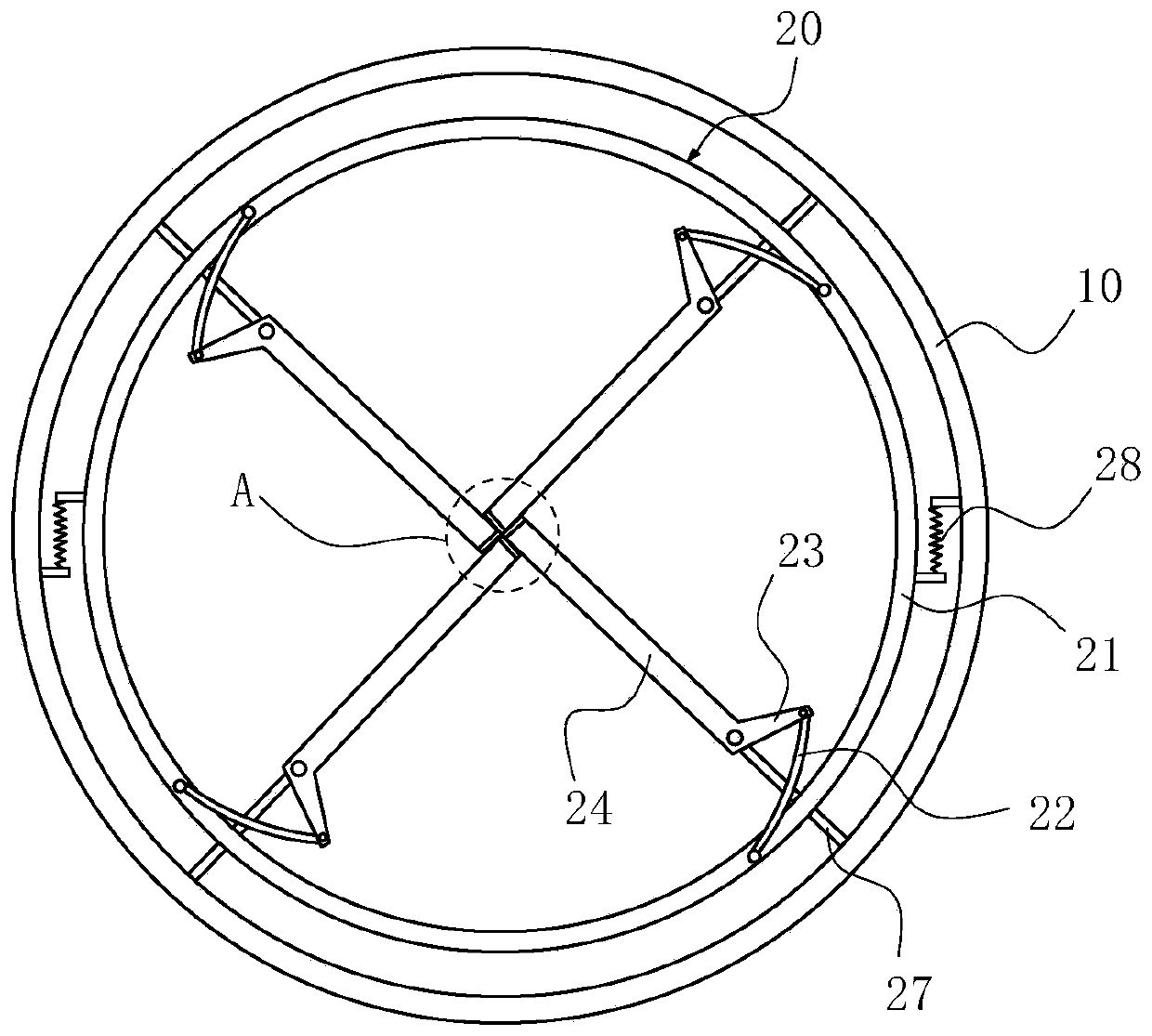

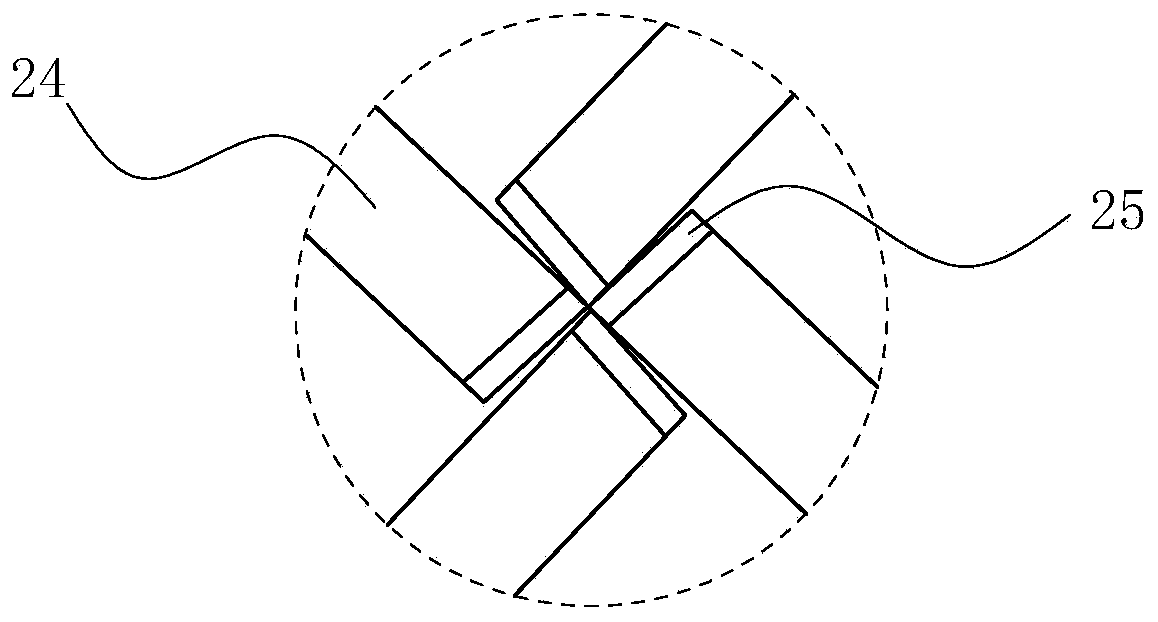

[0035] Such as figure 1 , figure 2 with image 3 As shown together, a trash can with a separable garbage bag includes a barrel body 10, the top of the barrel body 10 is provided with a discharge port, a bag cutting device 20 is provided in the barrel body 10, and the bag cutting device 20 is located below the discharge port. The bag cutting device 20 is connected with a driving mechanism for driving the bag cutting device 20 to move. The bag cutting device 20 includes a ring frame 21 connected with a driving mechanism and four swing arms that are evenly hinged on the ring frame 21. The end of the swing arm at the center of the ring frame 21 is equipped with a blade 25. The driving mechanism drives the ring frame 21 to rotate. , The swing arm drives the blade 25 to move away from the center position of the ring frame 21. The first swing arm 23, the second swing arm 24 and the blade 25 are all correspondingly arranged in four, which can be cut into a cross-shaped opening at the ...

Embodiment 2

[0045] This implementation mode is basically the same as the solution of Example 1, and the difference lies in:

[0046] Such as Image 6 As shown, the driving mechanism includes a motor 33. The output end of the motor 33 is connected with a gear 34 for transmission. The outer edge of the ring frame 21 is provided with external teeth that can mesh with the gear 34. The switch of the driving motor 33 can be arranged on the outside of the barrel 10. The bag cutting device 20 can be driven by pressing the switch to drive the motor 33 to cut the garbage bag.

Embodiment 3

[0048] This implementation mode is basically the same as the solution of Example 1, and the difference lies in:

[0049] Such as Figure 7 As shown, the driving mechanism includes a first pedal 35 and a first connecting rod 36 hinged to the first pedal 35. A first fulcrum 37 is fixed at the bottom of the barrel 10, and the first pedal 35 is hinged on the first fulcrum 37. A connecting member 38 is sleeved on the first connecting rod 36, and the inner side of the connecting member 38 is provided with internal threads to connect with the first connecting rod 36, and the outer side of the connecting member 38 is provided with gear teeth and external teeth provided on the outer edge of the ring frame 21 In the engagement, by stepping on the first step rod 35 to expose one end of the barrel body 10, the first connecting rod 36 can be moved upward, so that the connecting member 38 rotates to drive the ring frame 21 to rotate. Wherein, the barrel body 10 cannot be a separate structure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com