Rotary turning blade

A technology of turning and inserts, which is applied in the field of indexable turning inserts, can solve the problems of scratches, affecting the surface quality of workpieces, and cannot be applied at the same time, so as to achieve the effect of good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

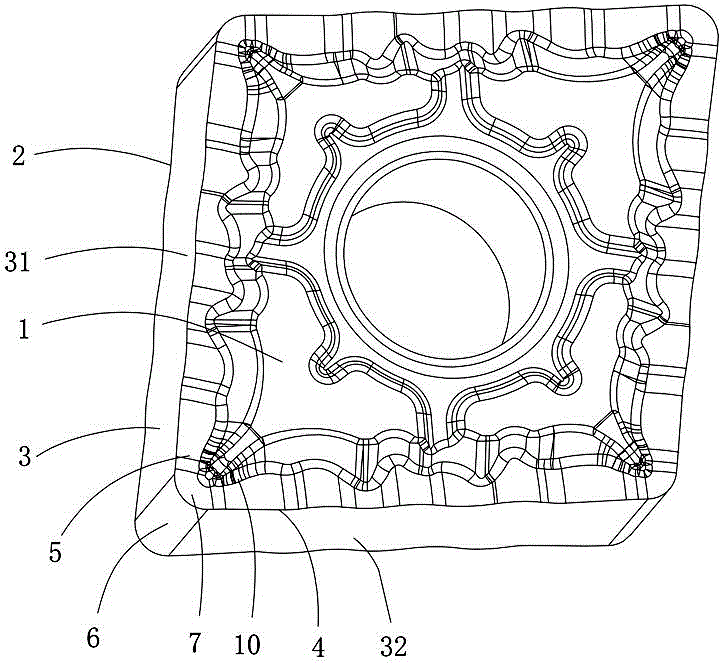

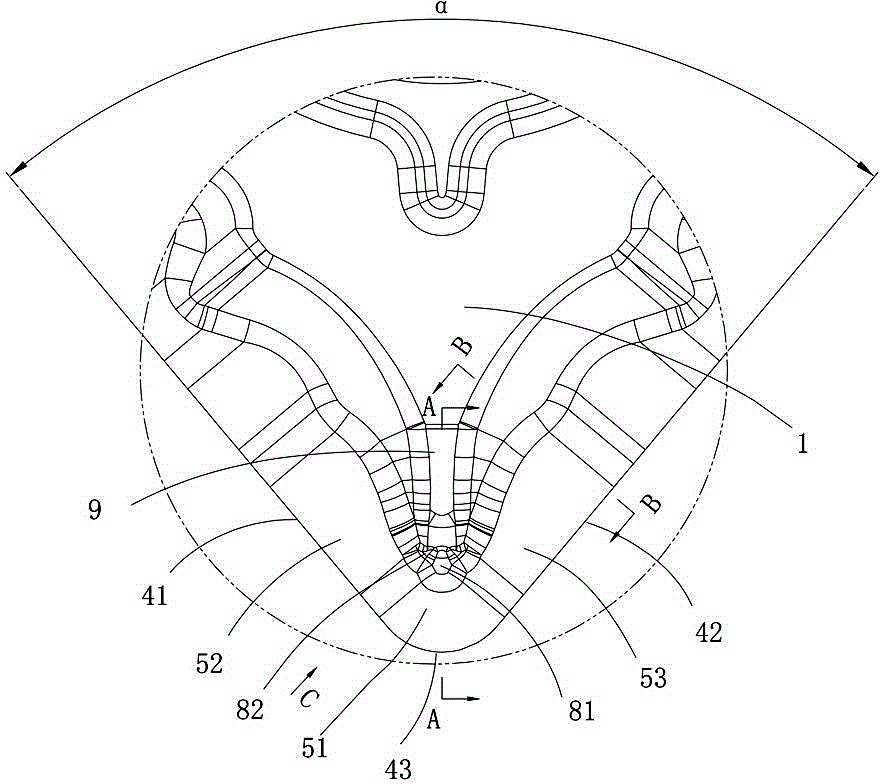

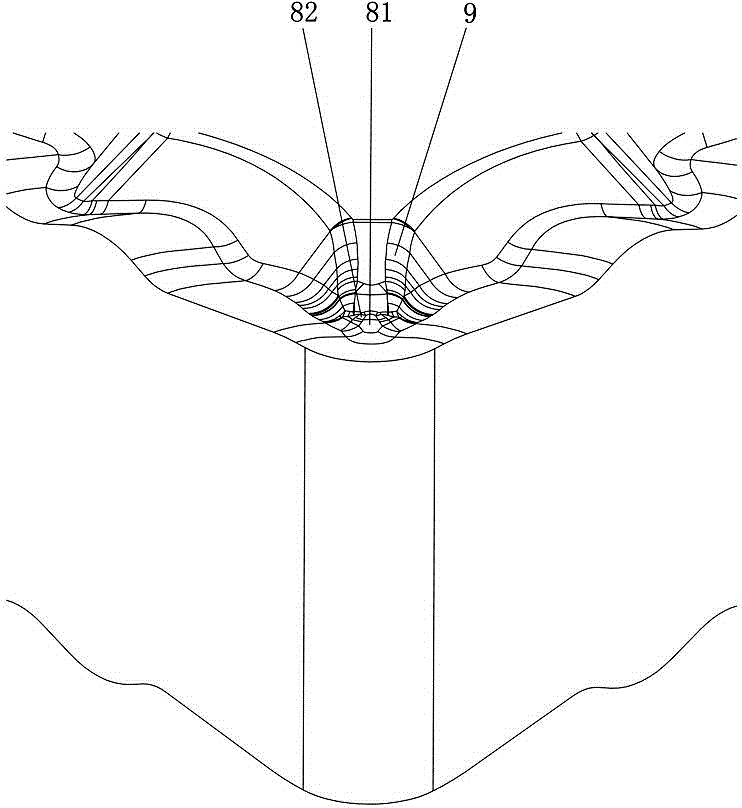

[0027] Figure 1 to Figure 6 An embodiment of the indexable turning insert of the present invention is shown, the indexable turning insert comprises an upper surface 1, a lower surface 2 and a plurality of side walls 3 connecting the upper surface 1, the lower surface 2, the upper surface 1 in The guiding surface formed by the cutting edge 4 is the rake face 5, and the two adjacent side walls 31, 32 are connected and transitioned by the cylindrical surface 6. The upper surface 1, the side walls 31, 32 and the cylindrical surface 6 intersect to form a tool tip 7, adjacent to each other. The included angle between the two side walls 31, 32 is the tool tip angle α, the cutting edge 4 includes a tool tip edge 43 and two side edges 41, 42, and the cutting edge 4 is symmetrical to the geometric bisector of the tool tip included angle α dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com