Potato lifter ladder-shaped digging shovel

A harvester, potato technology, applied in the direction of excavator harvester, excavator, harvester, etc., can solve the problems of poor soil crushing ability, large traction force, dullness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

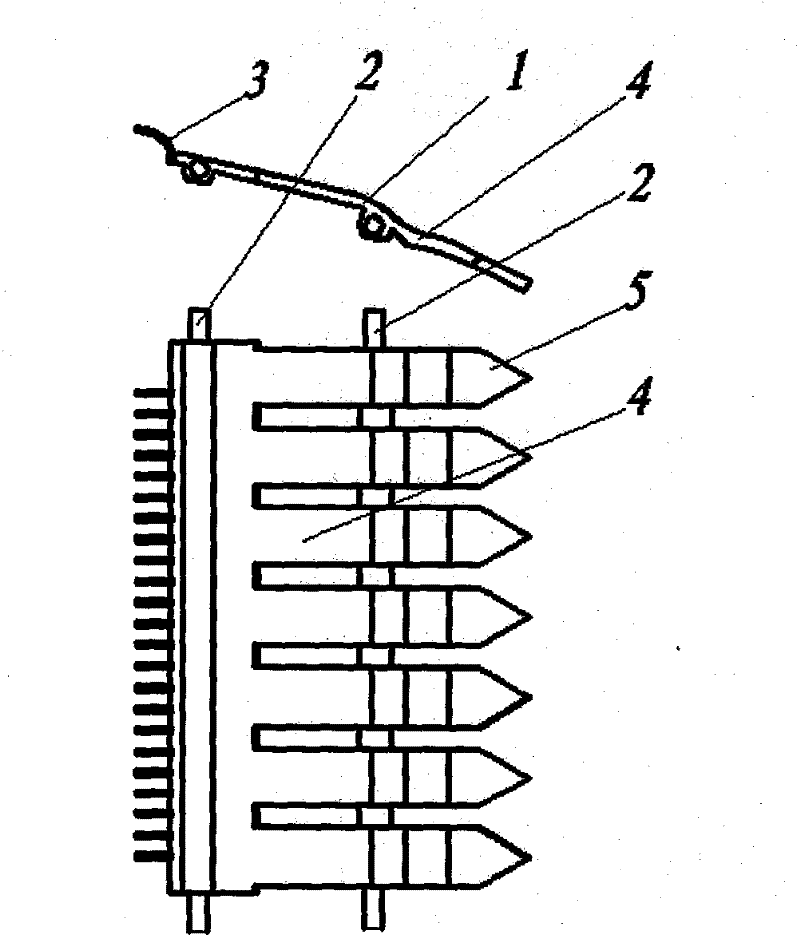

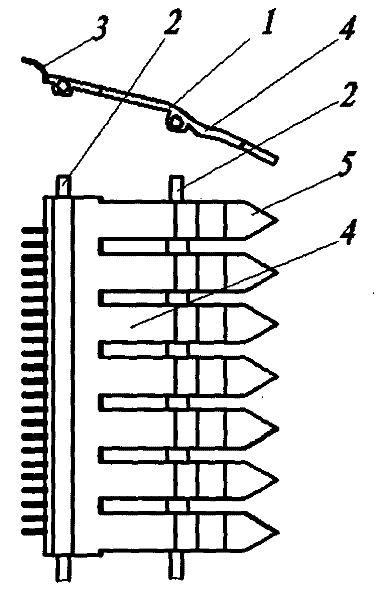

[0008] Embodiment 1, as shown in the figure, the potato harvester digging shovel comprises a shovel body (1), a connecting shaft (2) and a soil and potato dredging rod (3). The connecting shaft (2) of the excavating shovel is connected with the frame of the potato harvester, and along with the forward movement of the tractor, the soil furrow is raised, crushed and conveyed, and the soil and potato are sent to the separation mechanism through the soil and potato dredging column (3).

Embodiment 2

[0009] Example 2, as shown in the figure, the potato harvester digging shovel body (1) has a stepped cross-section. When the soil shovel passes through the shovel surface, the deformation of the soil shovel increases, making the shovel more crushable. The vertical distance from the tip of the shovel to the crushing conveying section (4) of the shovel body (1) should be less than the height of the soil compaction triangle formed by the common shovel with the length L as the base when the entry angle is 25°, which reduces the Working traction resistance of step shovel. The material of the lower surface of the stepped shovel shovel body (1) has higher hardness and wear resistance than the upper surface, so that the shovel has the function of self-sharpening and sharpening, and the soil penetration performance of the shovel is enhanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com