Personal care trimmer with high-reliability cutting edges and manufacturing method for personal care trimmer

A personal care and cutting edge technology, which is applied in metal processing and other directions, can solve the problems of inability to perform shearing operations, reduce shearing efficiency, and prone to cracks, etc., and achieve the effect of improving shearing efficiency, good shearing effect, and sharp cutting edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

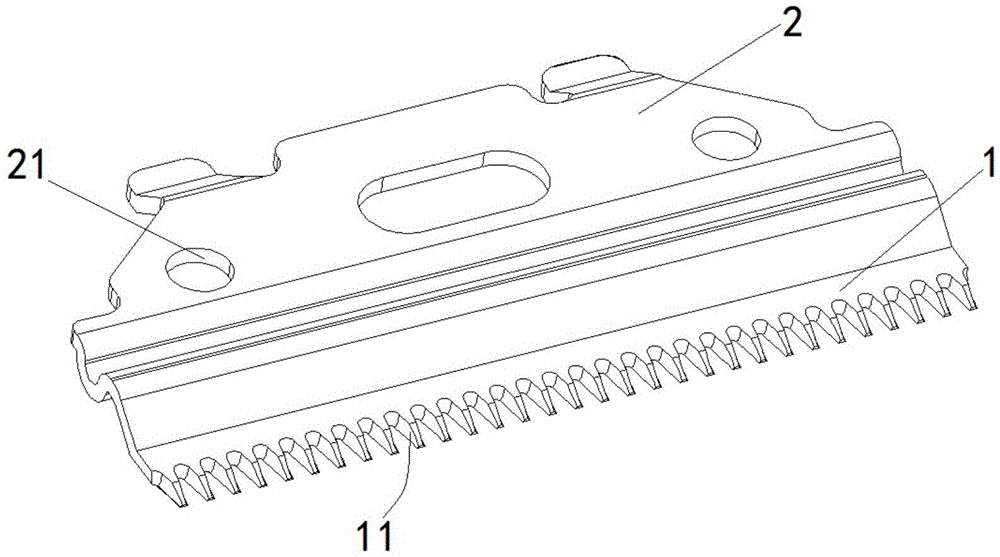

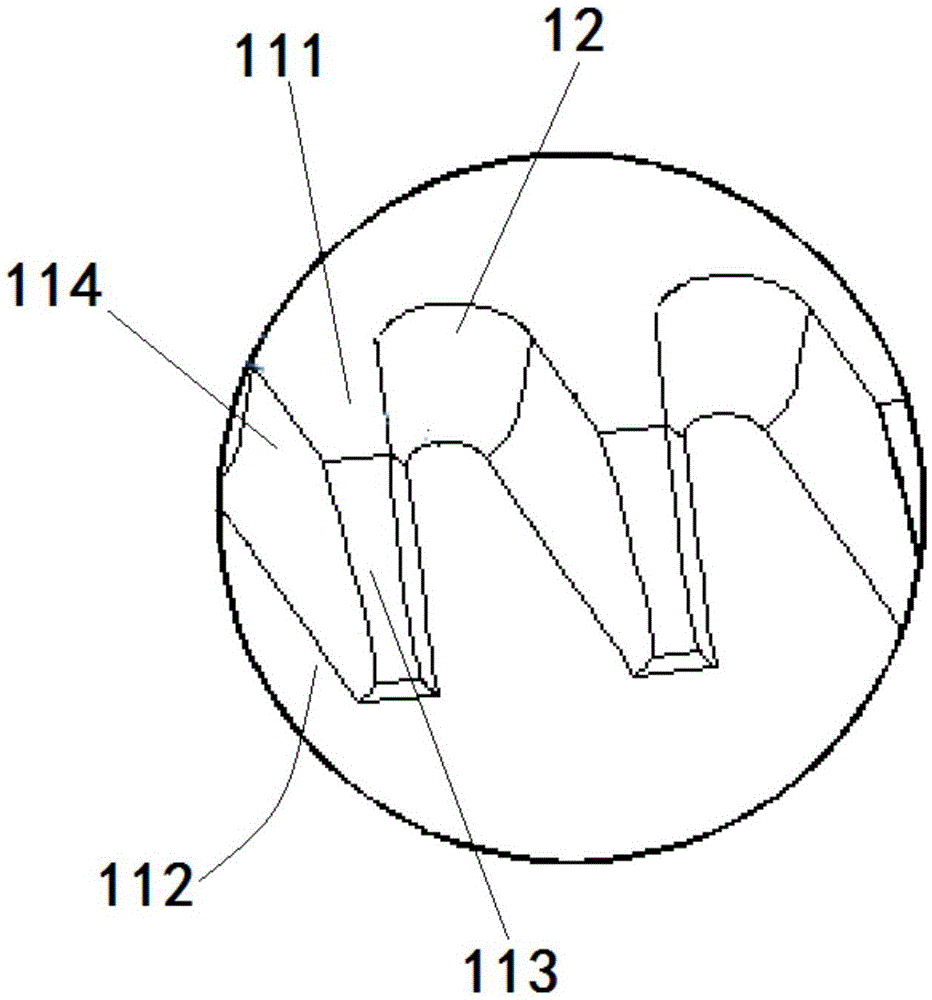

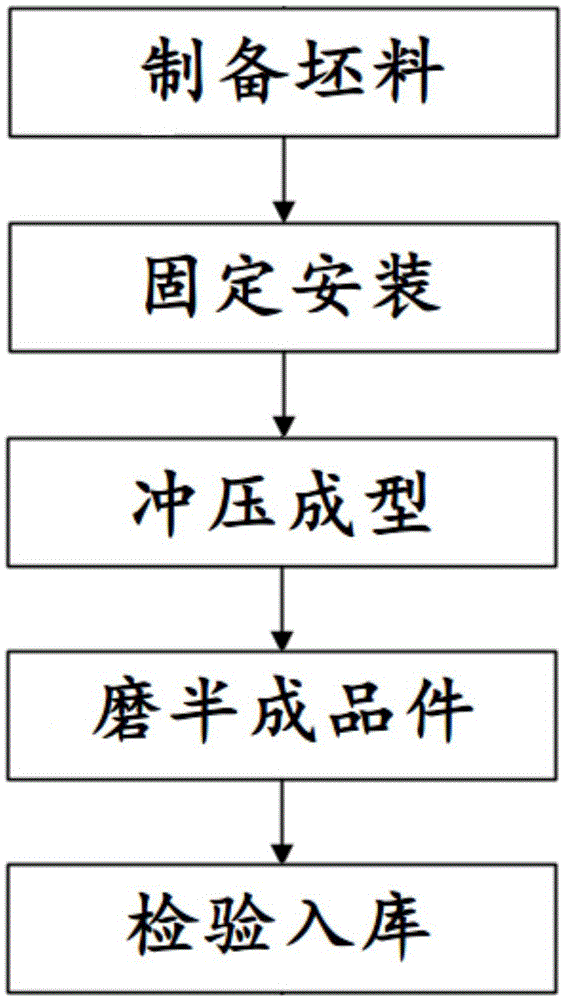

[0036] like figure 1 and figure 2 As shown, the present invention provides a personal care trimmer with a highly reliable cutting edge, comprising a blade body 2 and a cutter head 1 arranged at the end of the blade body 2, combs are evenly arranged on the cutter head 1 along the length direction Shape cutter tooth 11, described cutter tooth 11 comprises top surface 111, bottom surface 112, end surface, inclined surface 113 and two side surfaces 114, and described side surface 114 intersects with described top surface 111 to form the first cutting edge, and described side surface 114 and The bottom surface 112 intersects to form a second cutting edge, the slope 113 extends from the top surface 111 to the end surface, the slope 113 forms a third cutting edge with the side surface 114, and the side surface 114 is an inner concave arc Shaped surface; there is a connecting surface 12 between adjacent said cutter teeth 11, said connecting surface 12 is a concave arc surface, said ...

Embodiment 2

[0046] like figure 1 and figure 2 As shown, the present invention provides a personal care trimmer with a highly reliable cutting edge, comprising a blade body 2 and a cutter head 1 arranged at the end of the blade body 2, combs are evenly arranged on the cutter head 1 along the length direction Shape cutter tooth 11, described cutter tooth 11 comprises top surface 111, bottom surface 112, end surface, inclined surface 113 and two side surfaces 114,

[0047]The side surface 114 is a concave arc-shaped surface, and the concave arc-shaped surface is composed of a first vertical surface and a first arc-shaped surface, and the upper end of the first vertical surface intersects with the top surface 111 to form a first A cutting edge, the lower end of the first arc-shaped surface intersects with the bottom surface 112 to form a second cutting edge, the lower end of the first vertical surface is smoothly connected with the upper end of the first arc-shaped surface, and the inclined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com