Square-pipe punching machine

A punching machine and punching technology, applied in the direction of punching tools, metal processing, metal processing equipment, etc., can solve the problems of many burrs, low processing efficiency, affecting assembly and use, etc., to achieve smooth punching surface and high processing efficiency , beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

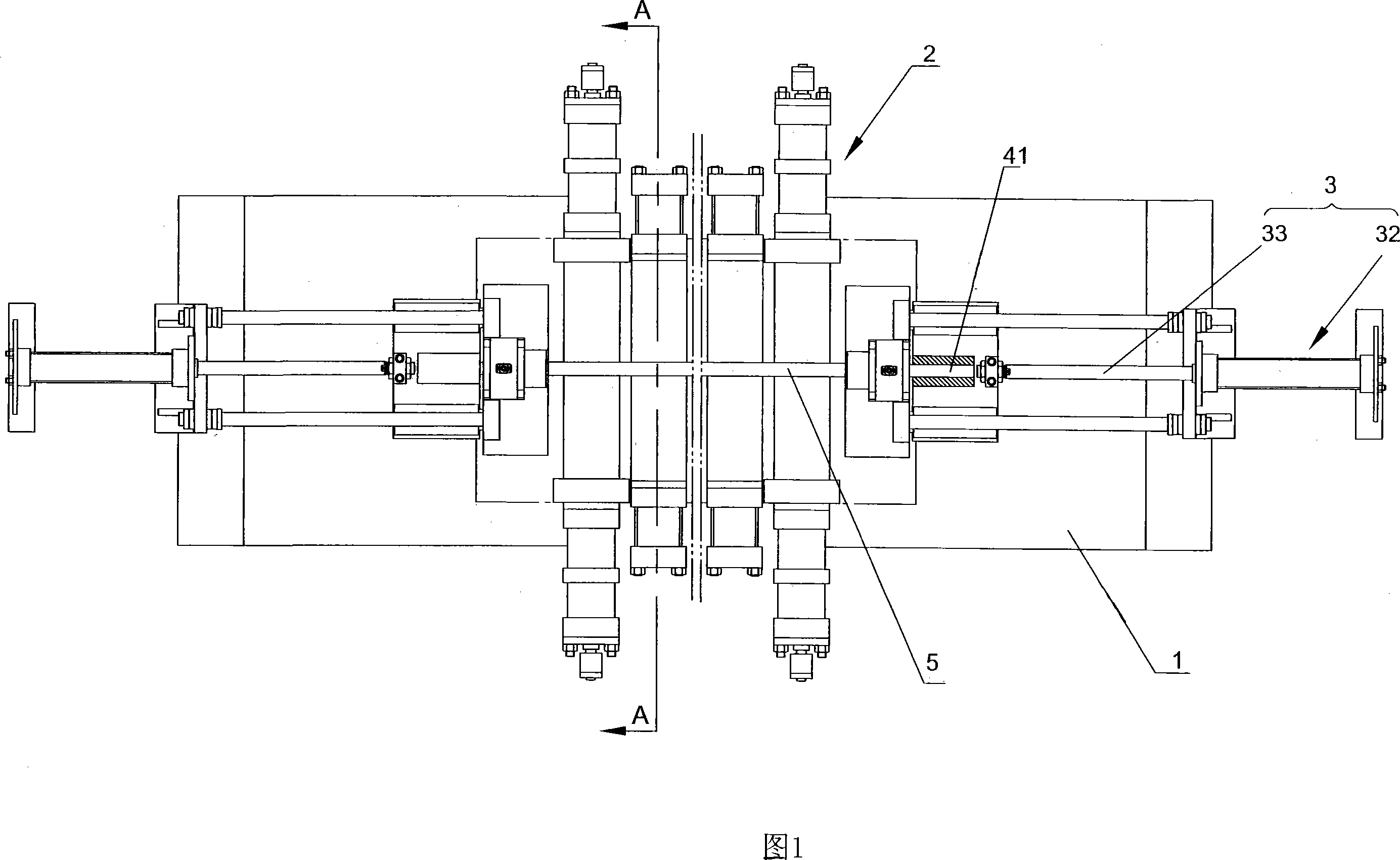

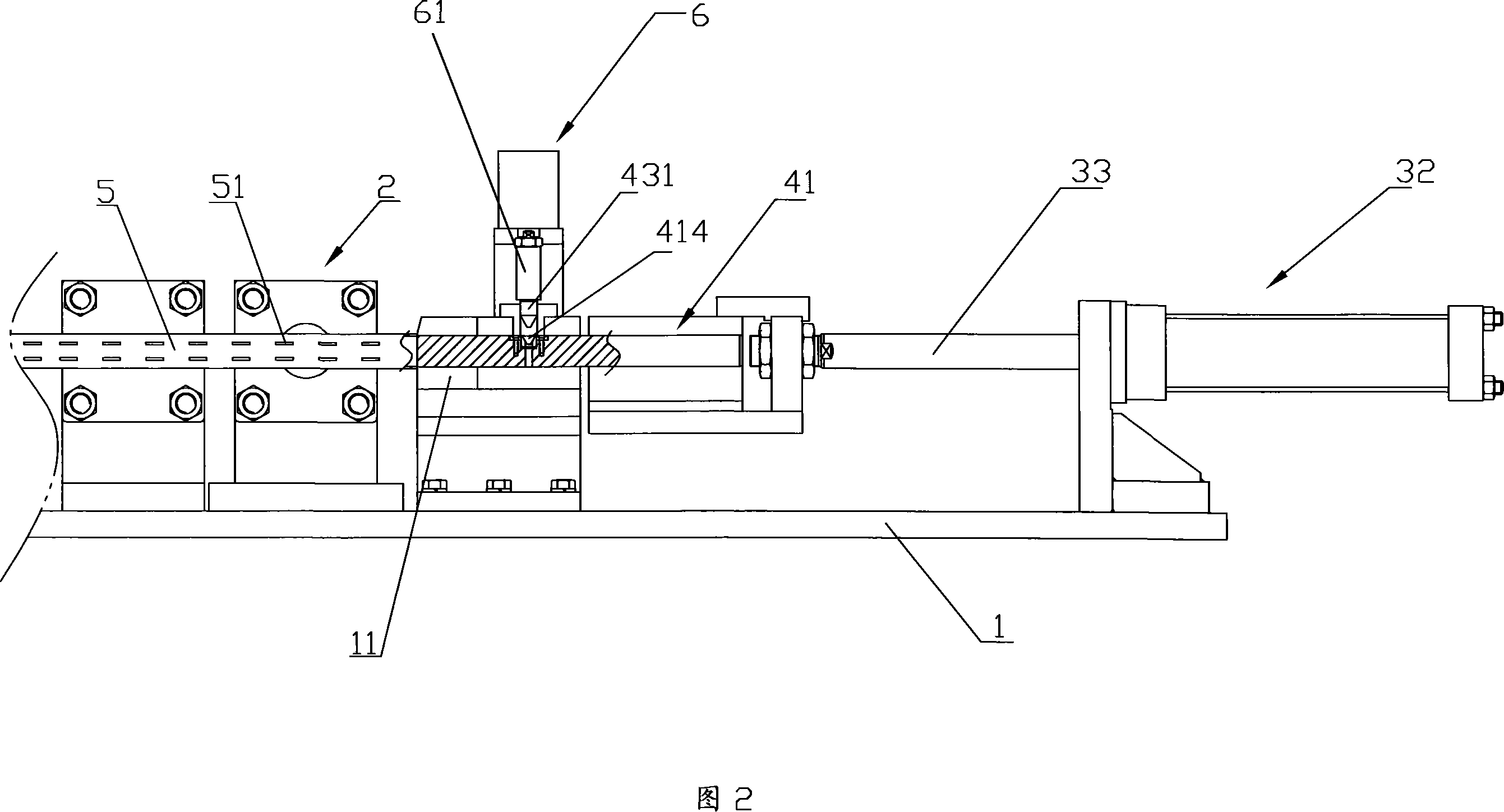

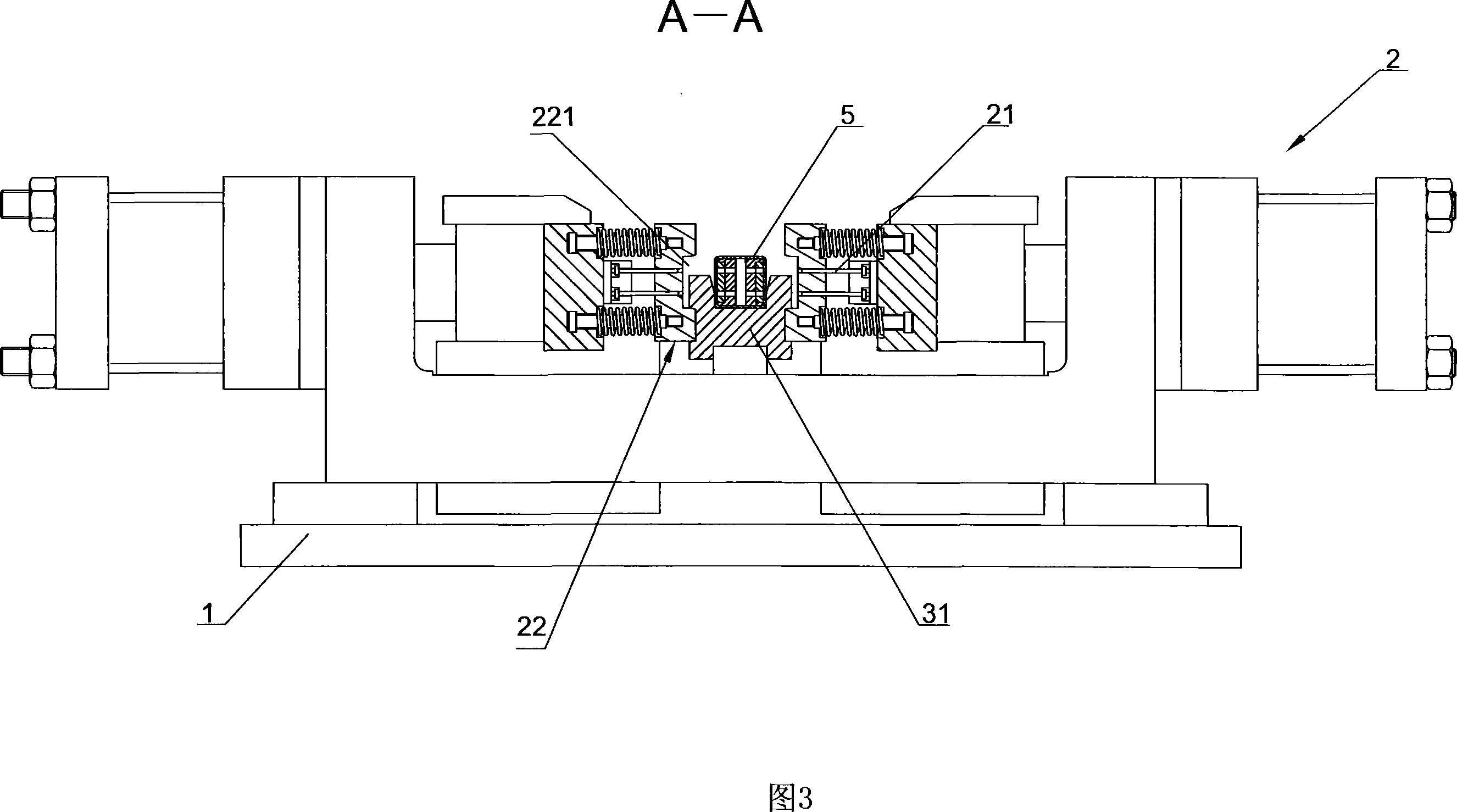

[0023] Referring to Figures 1 to 7, a square tube punching machine includes a frame 1, a plurality of tool holders oppositely arranged on both sides of the frame 1, a positioning mechanism for determining the punching position of a workpiece 5 4 and a clamping mechanism 3 for fixing the workpiece 5 to be processed in the axial direction. Each tool holder 2 is movably provided with a pair of punching pins 21 arranged up and down. When the workpiece 5 is fixed, it is located on the workpiece 5 The punching pins 21 on both sides of the punching needles are punched simultaneously, and the processing can be completed after two punching. The "upper" and "lower" positional relationships described in this specification correspond to the upper and lower positional relationships shown in FIG. 3.

[0024] Among them, the clamping mechanism 3 includes a bracket 31 arranged on the frame 1 for supporting the workpiece 5, clamping cylinders 32 respectively fixedly arranged on two opposite parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com