Shield machine duct piece hoisting device

A technology of hoisting device and shield machine, which is applied in the direction of shaft equipment, shaft lining, mining equipment, etc. It can solve the problems of trolley movement, high failure rate and failure during hoisting, and achieve the effect of small turning radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

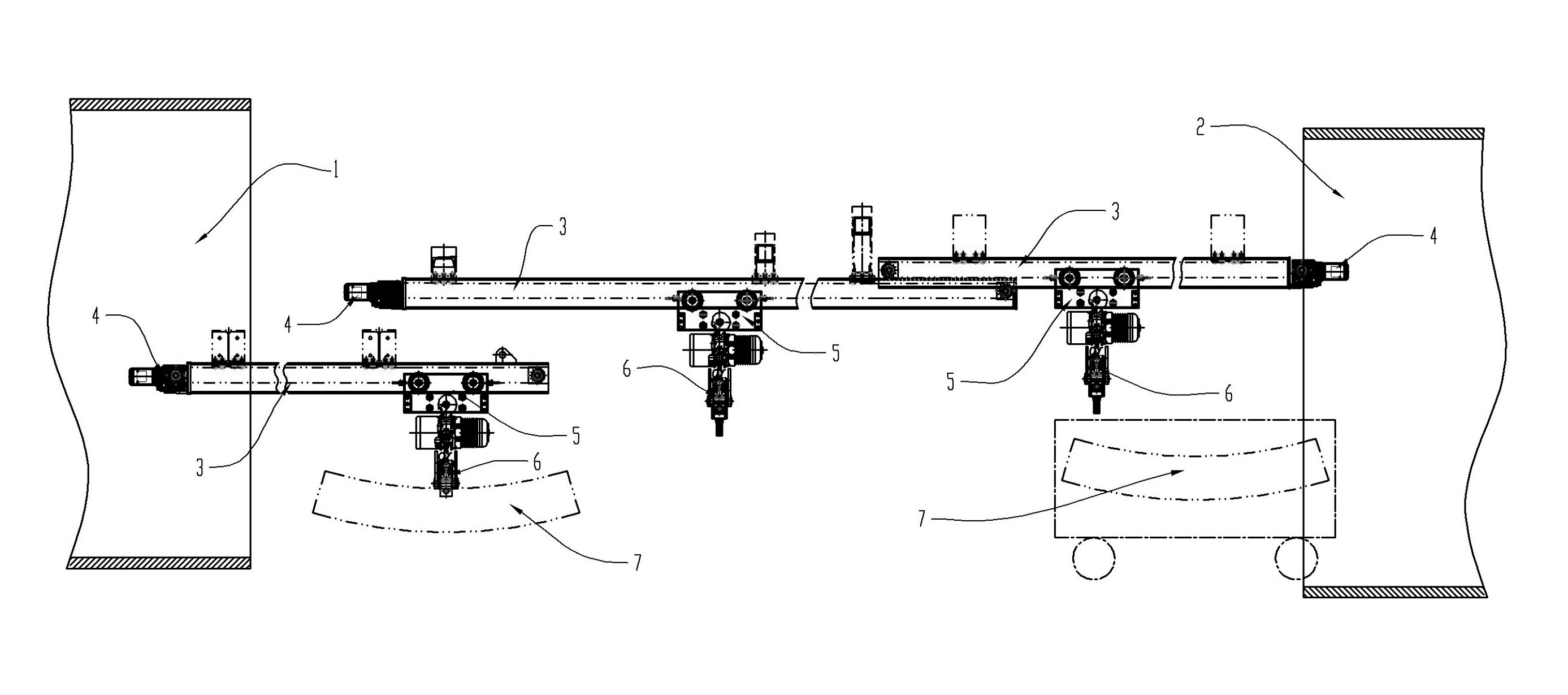

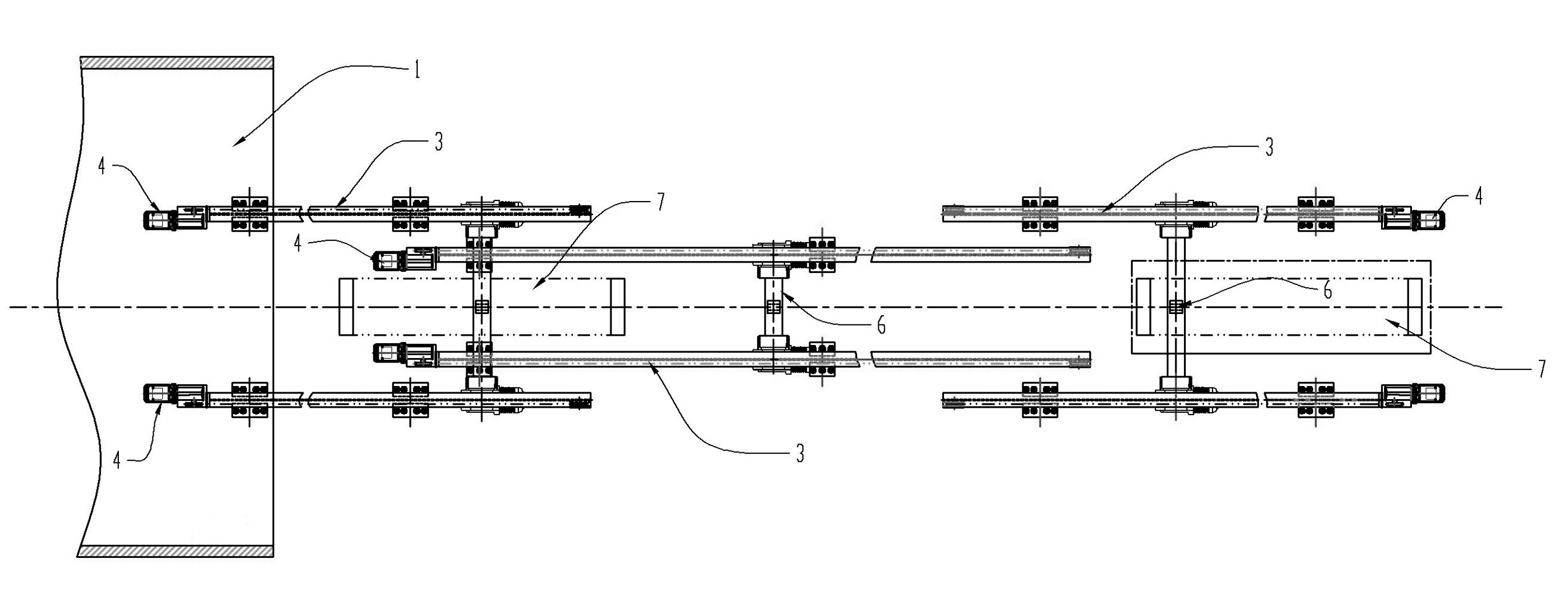

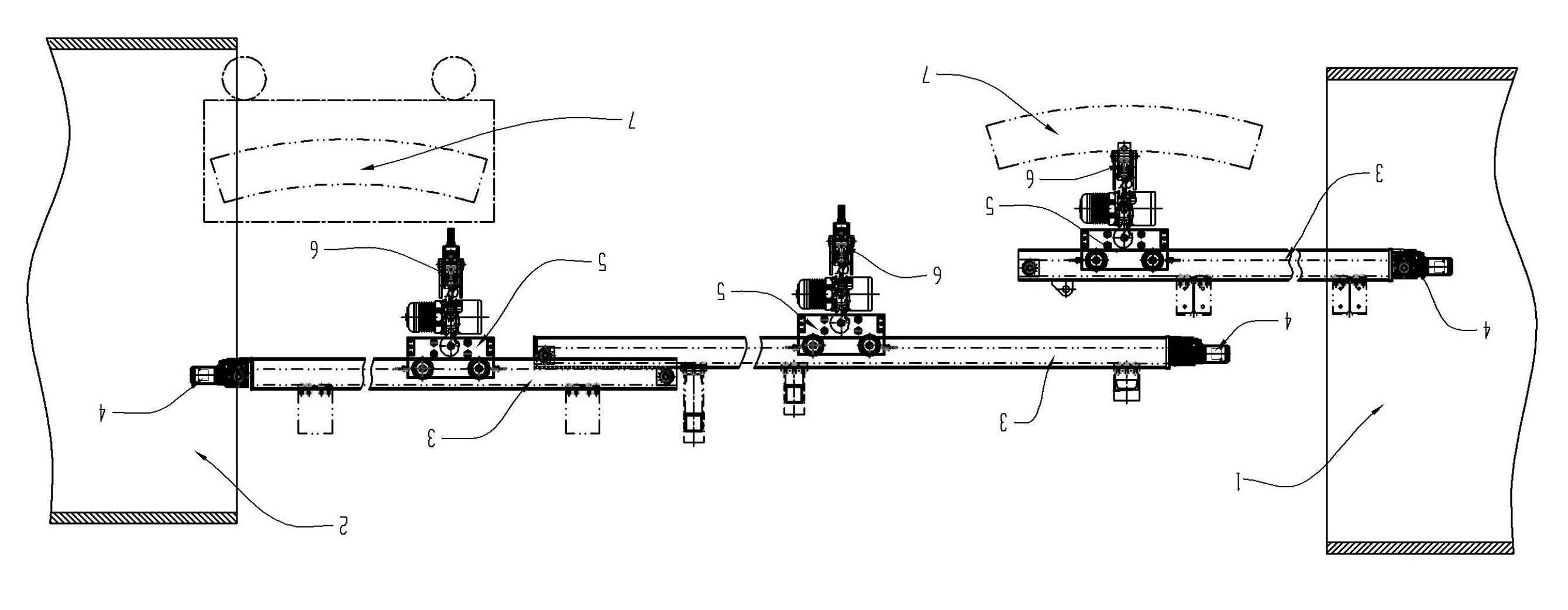

[0010] A shield machine segment hoisting device, such as figure 1 , figure 2 , the hoisting track between the tail of the shield body 1 and the supporting part 2 is divided into three sections, and each section of the hoisting track 3 is composed of a pair of parallel conveyor chain pairs, and each conveyor chain pair is a circular conveyor chain pair , its two ends are provided with sprocket wheel 31, and chain 32 is sleeved outside two sprocket wheels, and sprocket wheel connects motor 4, is driven by motor, and drives chain circulation to convey. The circular conveying chain on each section of the lifting track is equipped with a trolley 5, which is fixedly connected to the chain, and a spreader 6 for hanging the segment is installed at the bottom of the trolley; two adjacent sections of the lifting track are staggered from each other along the height direction, The ends overlap along the lifting direction, and the widths of the two pairs of circulating conveyor chains at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com