Large steel structure heel embedded part positioning device and method

A positioning device and steel structure technology, which are applied in basic structure engineering, construction and other directions, can solve the problems of tilting of bolt rods, difficult to realize the positioning of the bottom end of bolts embedded in column feet, etc., and achieve the effects of easy production, simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

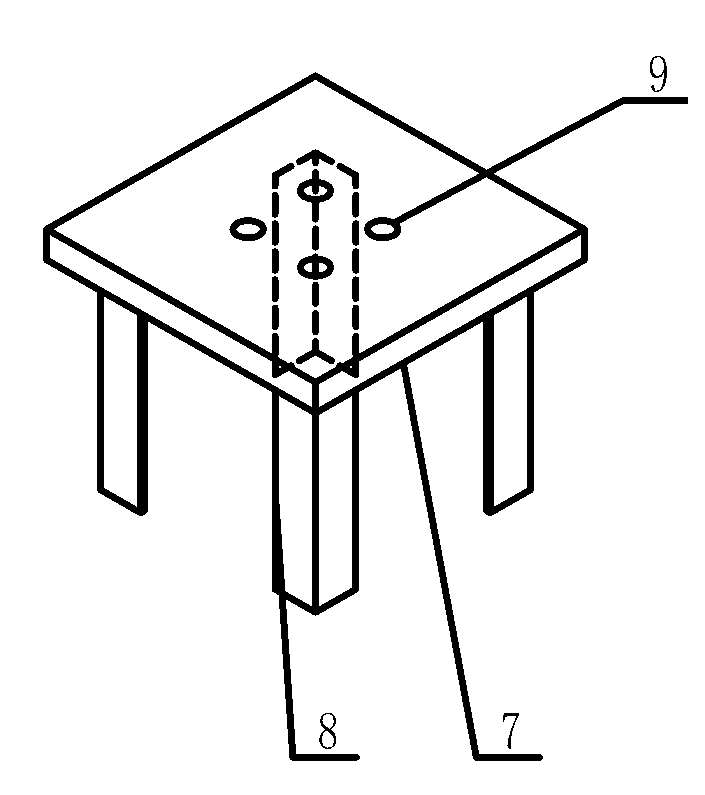

[0027] Embodiment 1, a large-scale steel structure column foot embedded parts positioning device, such as figure 1 As shown, it includes a positioning plate 7 and a connector 8. The positioning plate 7 is provided with a bolt hole 9, and the structure and position of the bolt hole 9 are matched with the pre-positioned column foot embedded parts 4 bolts. The positioning plate One side of 7 is provided with connecting piece 8, and positioning plate 7 is made of thick steel plate, and its thickness is 25mm; , and the length of each connector 8 is 220mm.

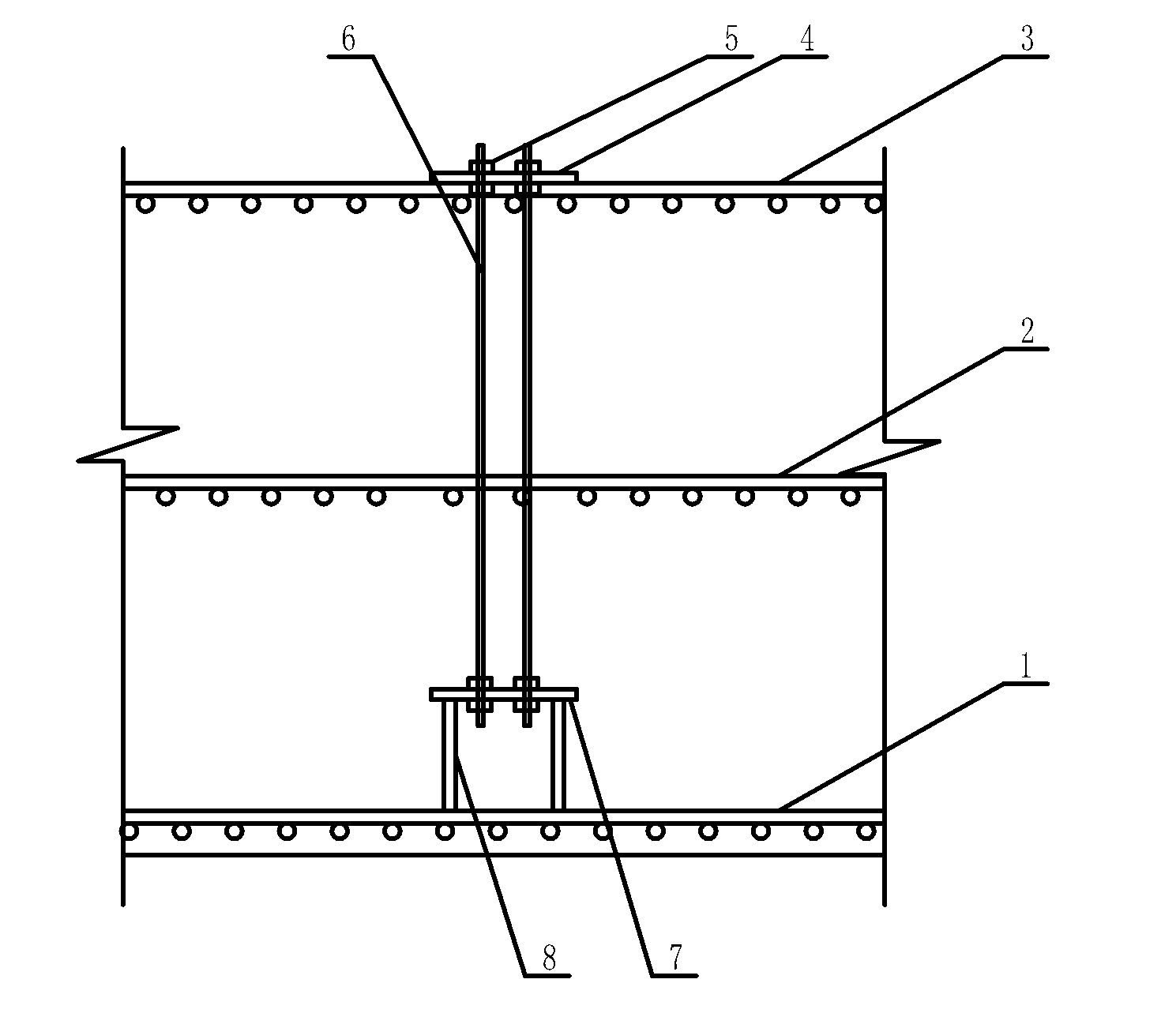

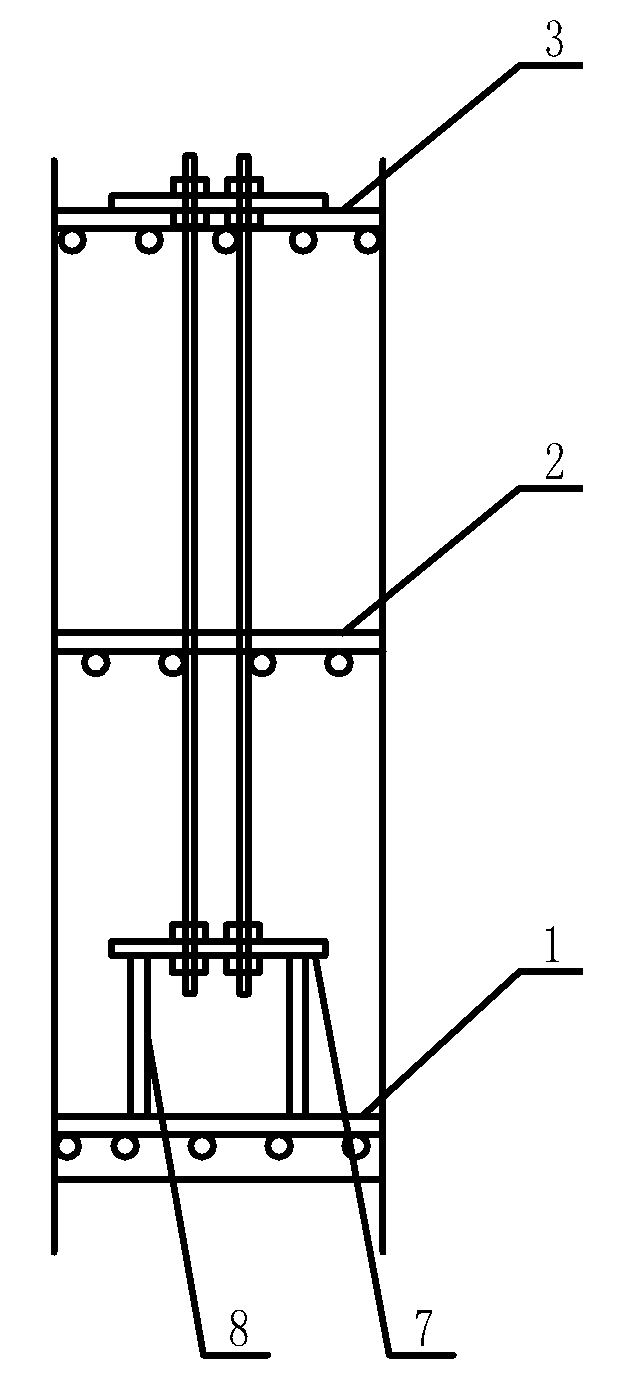

[0028] Positioning method for embedded parts of large steel structure columns, such as figure 2 , image 3 As shown, the method includes the following steps:

[0029] 1) Make the positioning plate 7, according to the diameter and relative position of the pre-installed and positioned column foot embedded parts 4 bolts, take a thick steel plate with a thickness of 25mm, and drill holes on it, so that the bolt holes 9 on the th...

Embodiment 2

[0037] Embodiment 2, large-scale steel structure column foot embedded parts positioning device, such as figure 1 As shown, it includes a positioning plate 7 and a connecting piece 8. The positioning plate 7 is provided with a bolt hole 9. The structure and position of the bolt hole 9 are matched with the pre-positioned column foot embedded parts 4 bolts. The positioning plate One side of 7 is provided with connector 8, and positioning plate 7 is made of thick steel plate, and its thickness is 30mm; , and the length of each connector 8 is 250mm.

[0038] Positioning method for embedded parts of large steel structure columns, such as figure 2 , image 3 As shown, the method includes the following steps:

[0039] 1) Make the positioning plate 7, according to the diameter and relative position of the pre-installed and positioned column foot embedded parts 4 bolts, take a thick steel plate with a thickness of 25mm, and drill holes on it, so that the bolt holes 9 on the thick st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com