Wind power blade preforming production line

A wind power blade and pre-forming technology, applied in wind power generation, wind turbines, engines, etc., can solve the problems of low production efficiency, easy cloth displacement, etc., to improve production efficiency, improve cutting accuracy, and high structural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

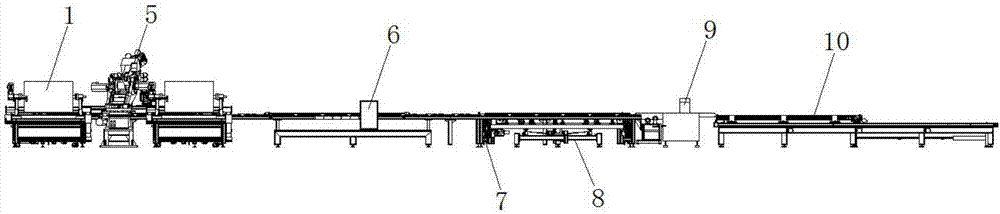

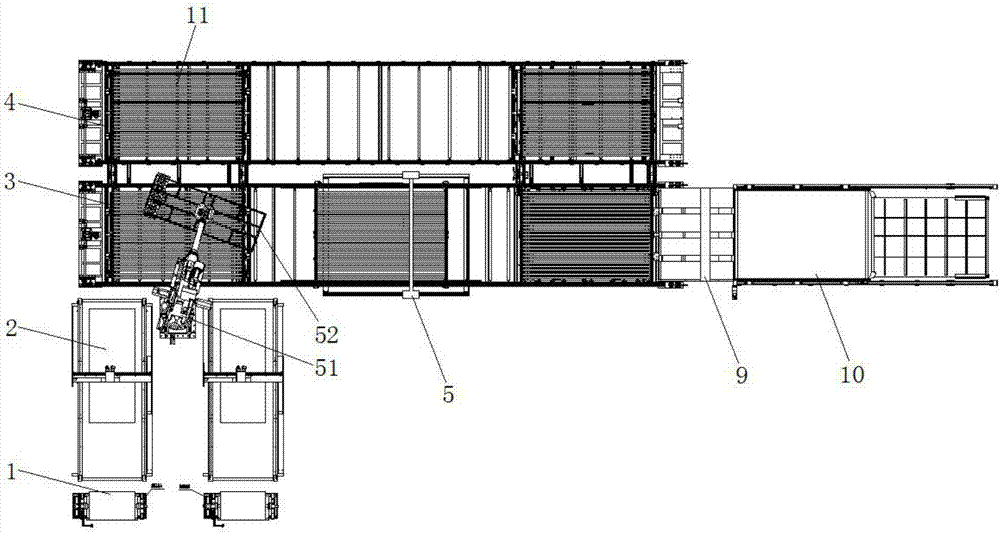

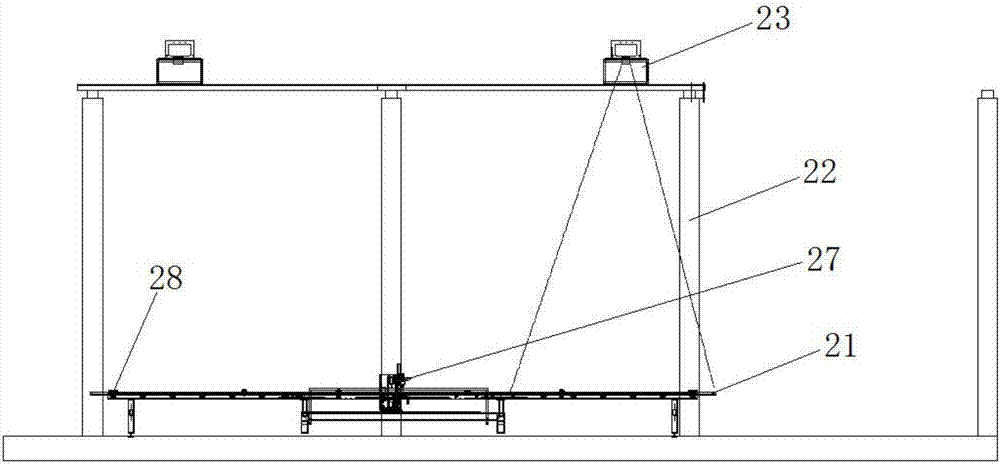

[0060] See figure 1 and figure 2 , the wind power blade preforming production line in this embodiment includes an unwinding mechanism 1, a cutting mechanism 2, a first conveying line 3, a second conveying line 4, a grasping and stacking mechanism 5, a sewing mechanism 6, and a lifting and translation mechanism 7 , Lifting cloth taking mechanism 8, metal detection mechanism 9, stacking and discharging mechanism 10 and turnover frame 11.

[0061]Both the unwinding mechanism 1 and the cutting mechanism 2 are provided with two groups. The two groups of unwinding mechanisms 1 are arranged close to the input ends of the two groups of cutting mechanisms 2 respectively. The output end of the cutting mechanism 2 is set close to the input end of the first conveying line 3 . The second conveying line 4 is arranged parallel to and adjacent to the first conveying line 3 , and the conveying direction of the second conveying line 4 is opposite to that of the first conveying line 3 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com