Heat forming method for aluminum alloy sheet metal part after solid solution and water quenching

A solid solution water quenching, aluminum alloy technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of large changes in shape and size, slow cooling and quenching speed, and high requirements for forming equipment, so as to avoid changes in the shape and size of parts. , to ensure the shape and size accuracy, the effect of high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

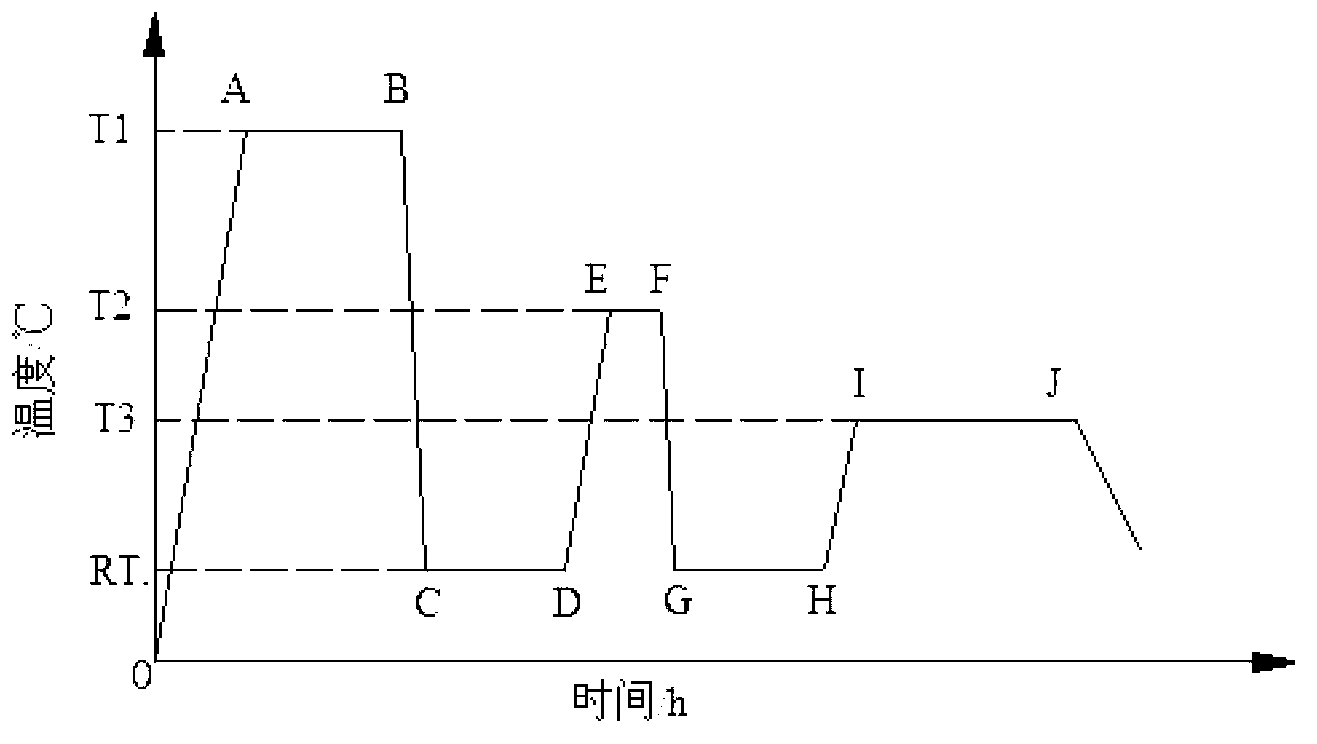

[0022] Specific Embodiment 1: In this embodiment, a method for thermoforming an aluminum alloy sheet metal part after solid solution water quenching is carried out according to the following steps:

[0023] 1. Put the aluminum alloy slab in the heating furnace, and heat it for 30-180 minutes at a temperature of 450-575°C for solid solution. After the solid solution is completed, take it out for water quenching;

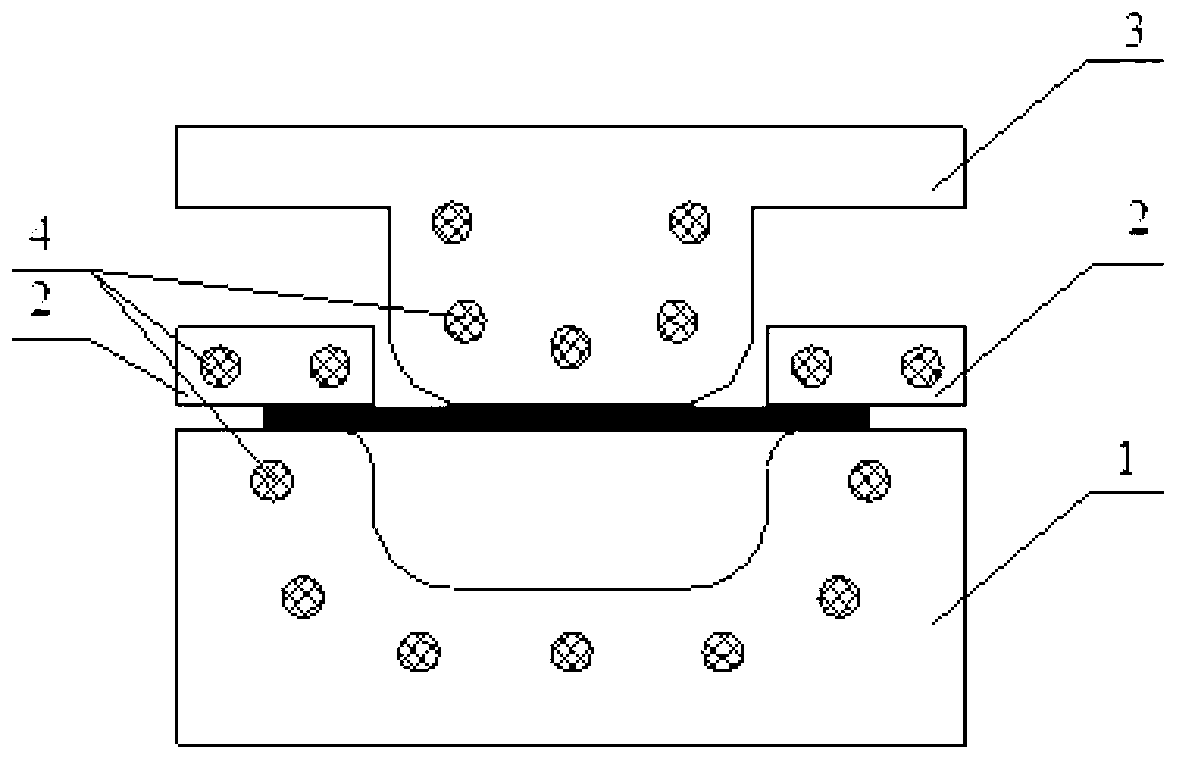

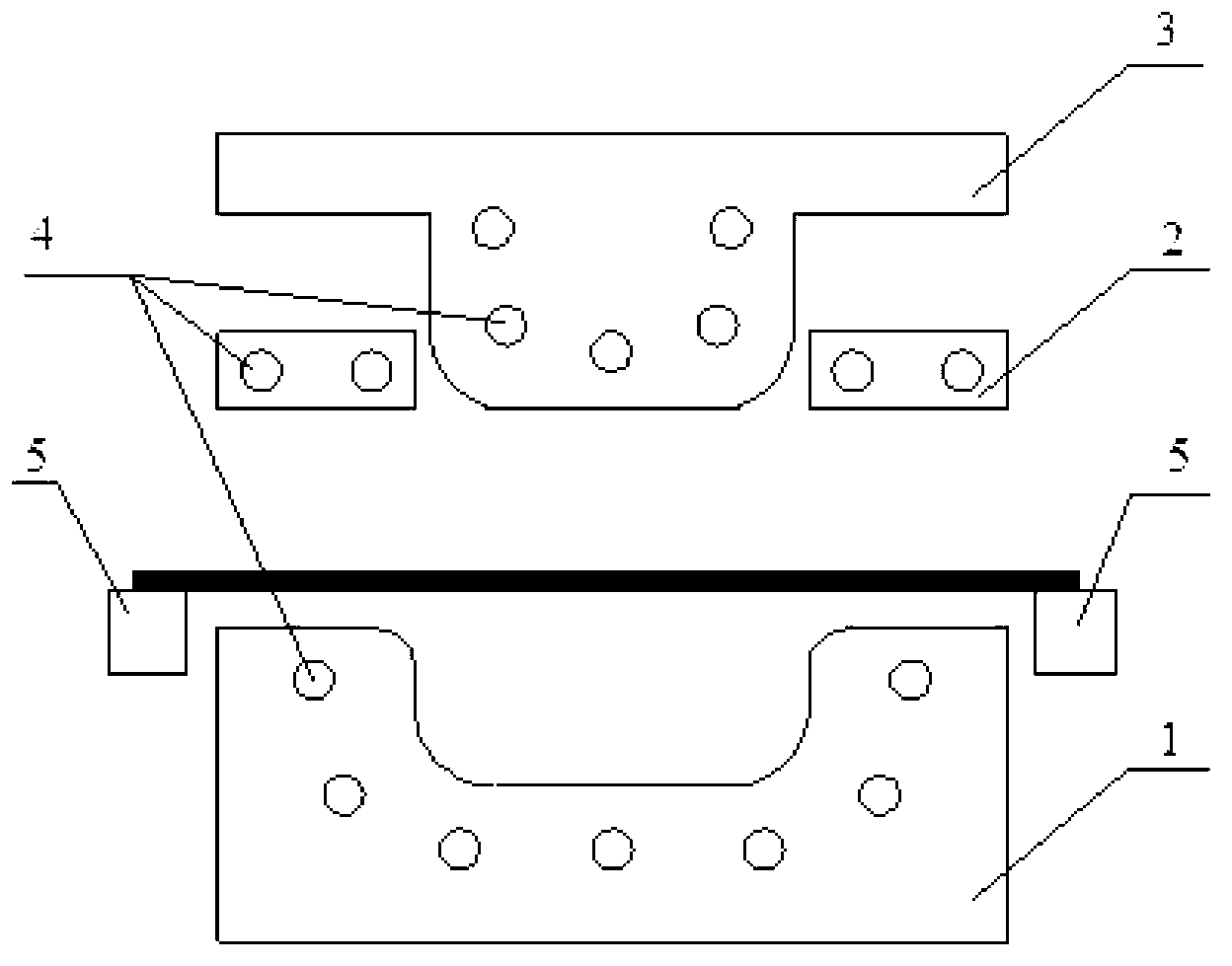

[0024] 2. Heat the mold to a temperature of 150~400°C;

[0025] 3. Put the aluminum alloy slab processed in step 1 into the mold processed in step 2 and heat it to a temperature of 150~400°C, then close the molds and press to complete the forming of aluminum alloy sheet metal parts;

[0026] 4. Remove the formed aluminum alloy sheet metal parts, cool to room temperature, and then perform aging treatment at a temperature of 120-250 °C to obtain the final aluminum alloy sheet metal parts.

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that in Step 2, the mold is heated by a heating rod built into the mold, and other steps and parameters are the same as Embodiment 1.

specific Embodiment approach 3

[0028] Specific embodiment three: this embodiment is the same as specific embodiment one or two: before step three, the aluminum alloy slab processed in step one is preheated to 150~400°C, other steps and parameters are the same as the specific embodiment One or two the same.

[0029] In this embodiment, the aluminum alloy slab is preheated, which shortens the heating time of the aluminum alloy slab in the mold and shortens the forming cycle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com