Pyrophyllite block compression forming device and method

A pyrophyllite block, press-forming technology, applied in the field of superhard material synthetic auxiliary tools, can solve the problems of large manual weighing error, high production cost, inaccurate working pressure, etc. Uniform effect of process and loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

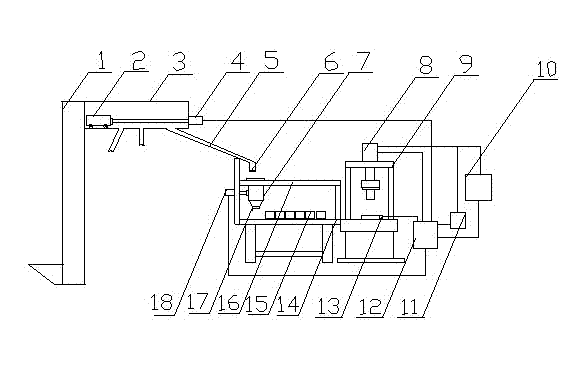

[0021] see figure 1 , a pyrophyllite block press forming device, comprising multiple sets of presses 9, hydraulic oil pumps 10, and molding dies 15, the presses 9 are connected with a mold charging mechanism, a feeding mechanism and a pressure control system. Wherein, the mold charging mechanism has a workbench 14, and the top of the workbench 14 is provided with a guide rail 16, a charging barrel 7 and a charging liquid cylinder 18 connected with the charging barrel 7, and the charging barrel 7 and the guide rail 16 Slidingly connected, and moved along the guide rail 16 under the drive of the charging liquid cylinder 18, the bottom of the charging barrel 7 is provided with a blanking port. The scraper 17 is set at the bottom of the charging barrel 7, so that the raw material loaded into the molding die 15 is scraped off, so that the raw material loading amount of each molding die 15 is consistent. The feeding mechanism is composed of a raw material lifting mechanism 1 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com