Horseshoe-shaped part machining positioning device and machining method thereof

A part processing and positioning device technology, which is applied in the field of processing horseshoe-shaped parts of military equipment, can solve the problems of easy out-of-tolerance efficiency, low processing efficiency, and high cost, and achieve the goal of ensuring the accuracy of shape and size, reducing production costs, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

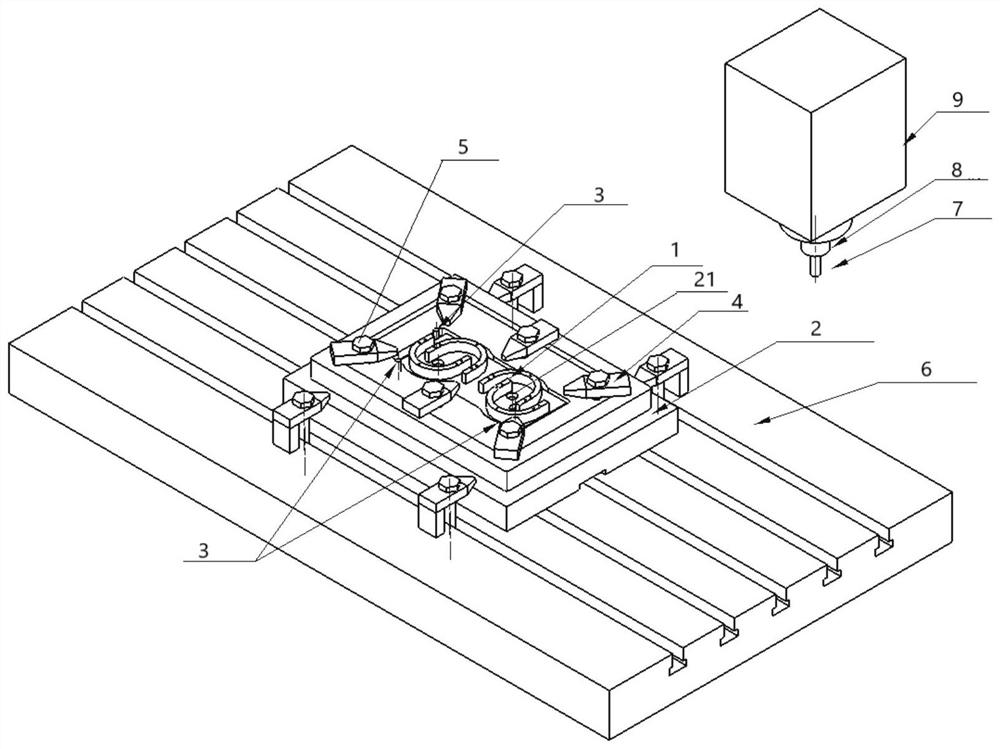

[0051] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0052] 1. Technical analysis of horseshoe parts

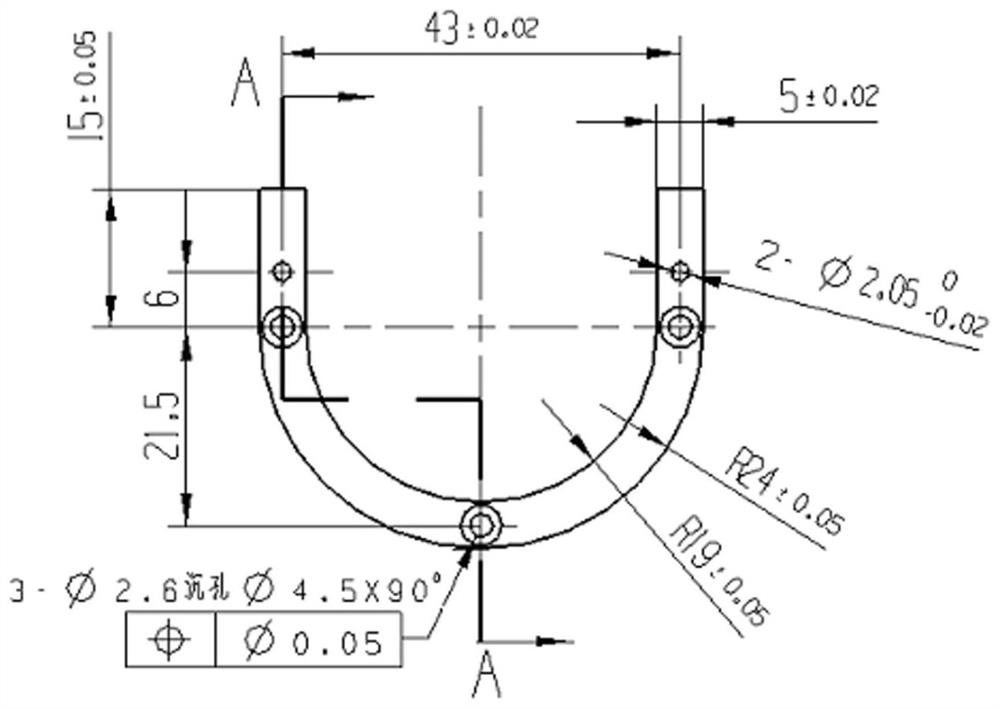

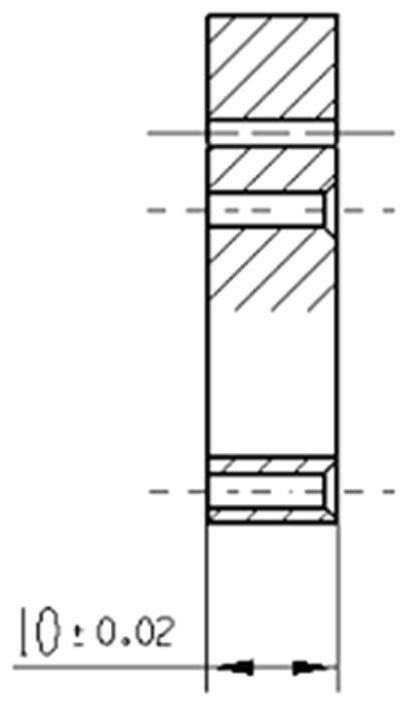

[0053] Such as figure 1 , figure 2 Shown is a microwave component of a certain type of equipment to be processed and formed in the present invention, which is formed by subsequent processing and milling. Analyze the characteristics, basic structure and precision requirements of the processed parts.

[0054] 1.1 Analysis of the characteristics of parts layout

[0055] The parts layout is H62 brass plate, which has good mechanical properties, good plasticity in hot state, acceptable plasticity in cold state, good machinability, easy welding, and corrosion resistance.

[0056] 1.2 Part shape analysis

[0057] Analyze parts such as figure 1 As shown, the parts are slender and U-shaped, and it is difficult to clamp them in single-piece processing, and the U-shaped opening is subjected to the cutting force during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com