Thin film thickness measurement method and system

A technology for measuring system and film thickness, which is applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of reducing the accuracy of film thickness measurement and the difficulty of obtaining fringe period information, etc., and achieve easy online measurement, avoid mechanical rotation process, The effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

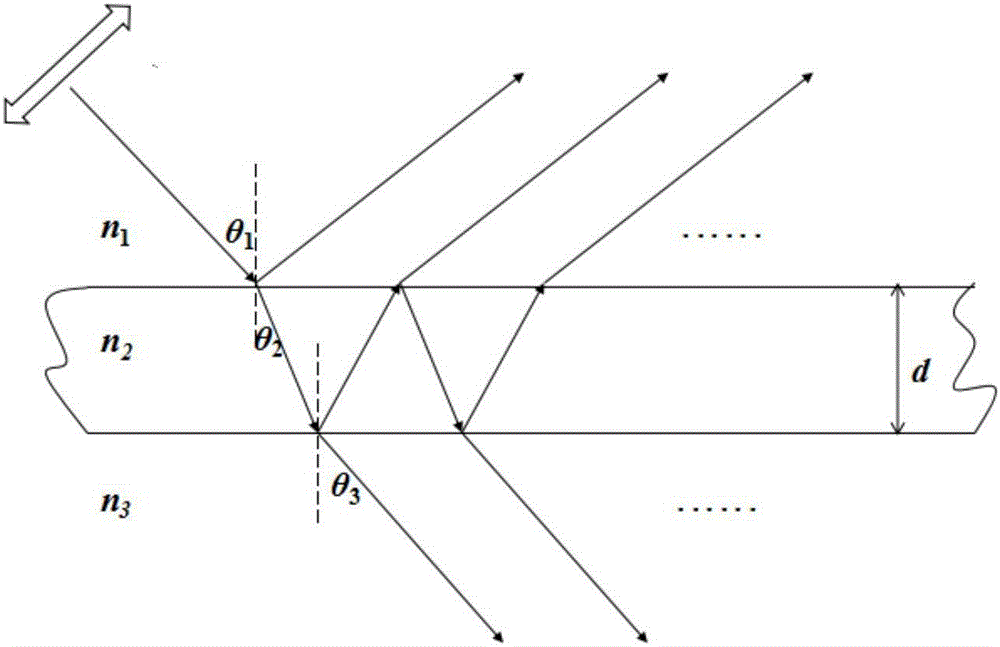

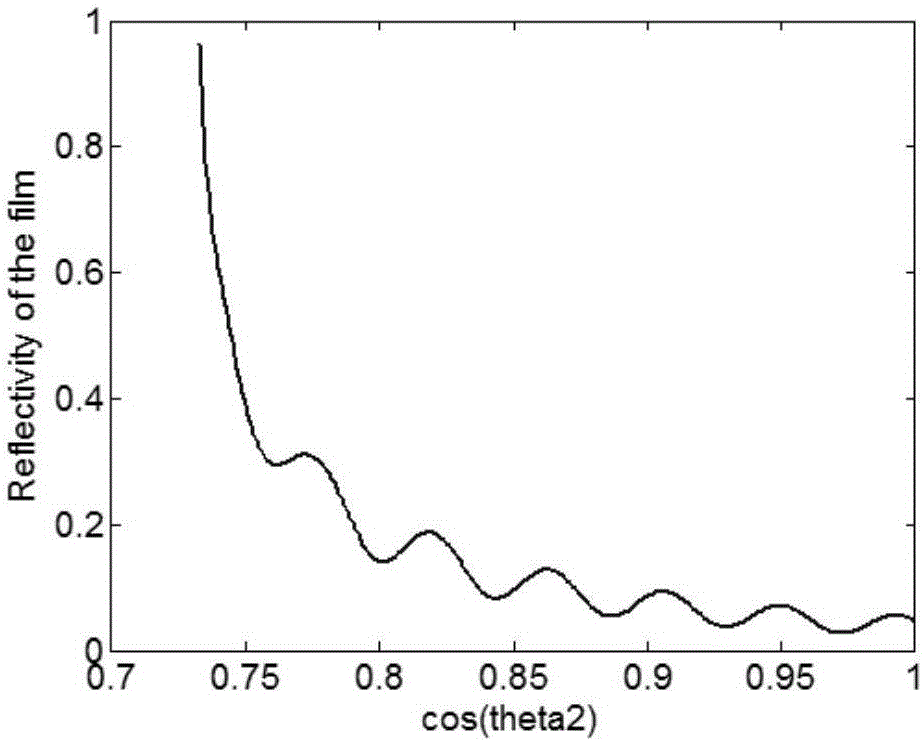

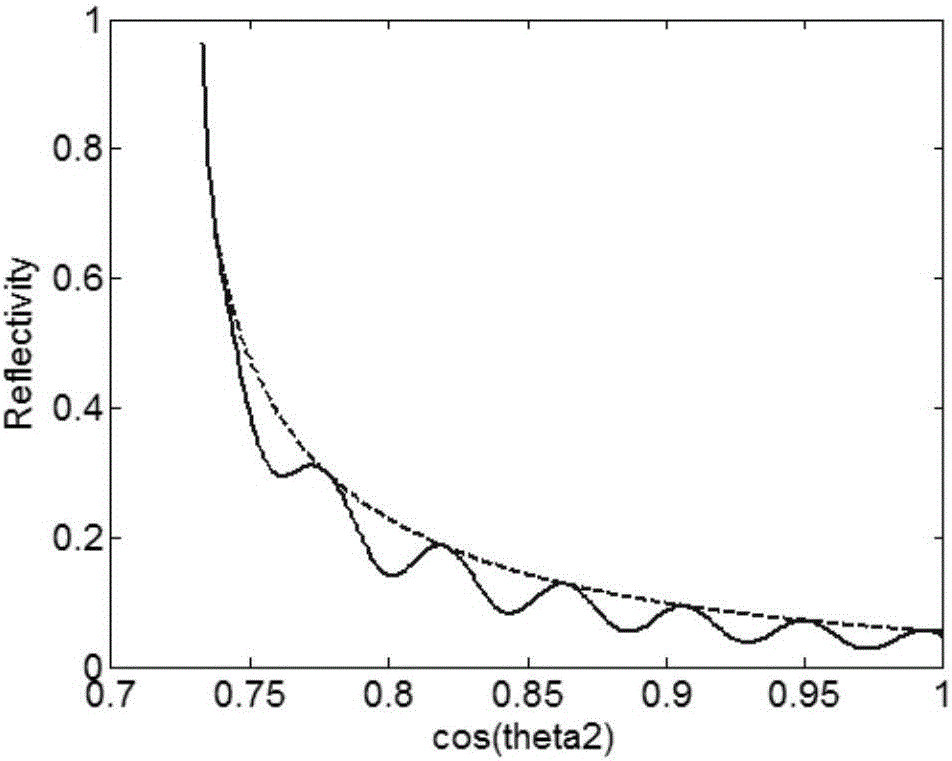

[0054] The present invention adopts the relationship between the intensity of the reflected light beam on the surface of the sample and the angle of incidence, that is, the R(θ) function curve, combines Fourier transform to establish the relationship between the spectral position of the R(θ) curve and the film thickness, and utilizes The corresponding relationship between the air domain and the frequency domain, the frequency domain information is used to obtain the fringe period in the air domain, and the thickness of the film to be measured is analyzed. Not only the structure is simple, the cost is low, and the film thickness measurement speed is fast, but also there is no scanning device and machinery for incident angle or reflection angle. The rotating device can minimize the sources of measurement errors, and the stability of the measuring device is high.

[0055] The present invention will be described in detail below in conjunction with the accompanying drawings and spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com