Cylindrical battery housing and cylindrical battery

A cylindrical battery, cylindrical technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of difficulty in welding the conductive terminals of the battery and the battery shell, difficulty in welding the cover plate, and difficult position control, etc., to avoid The effect of battery explosion, good welding quality and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

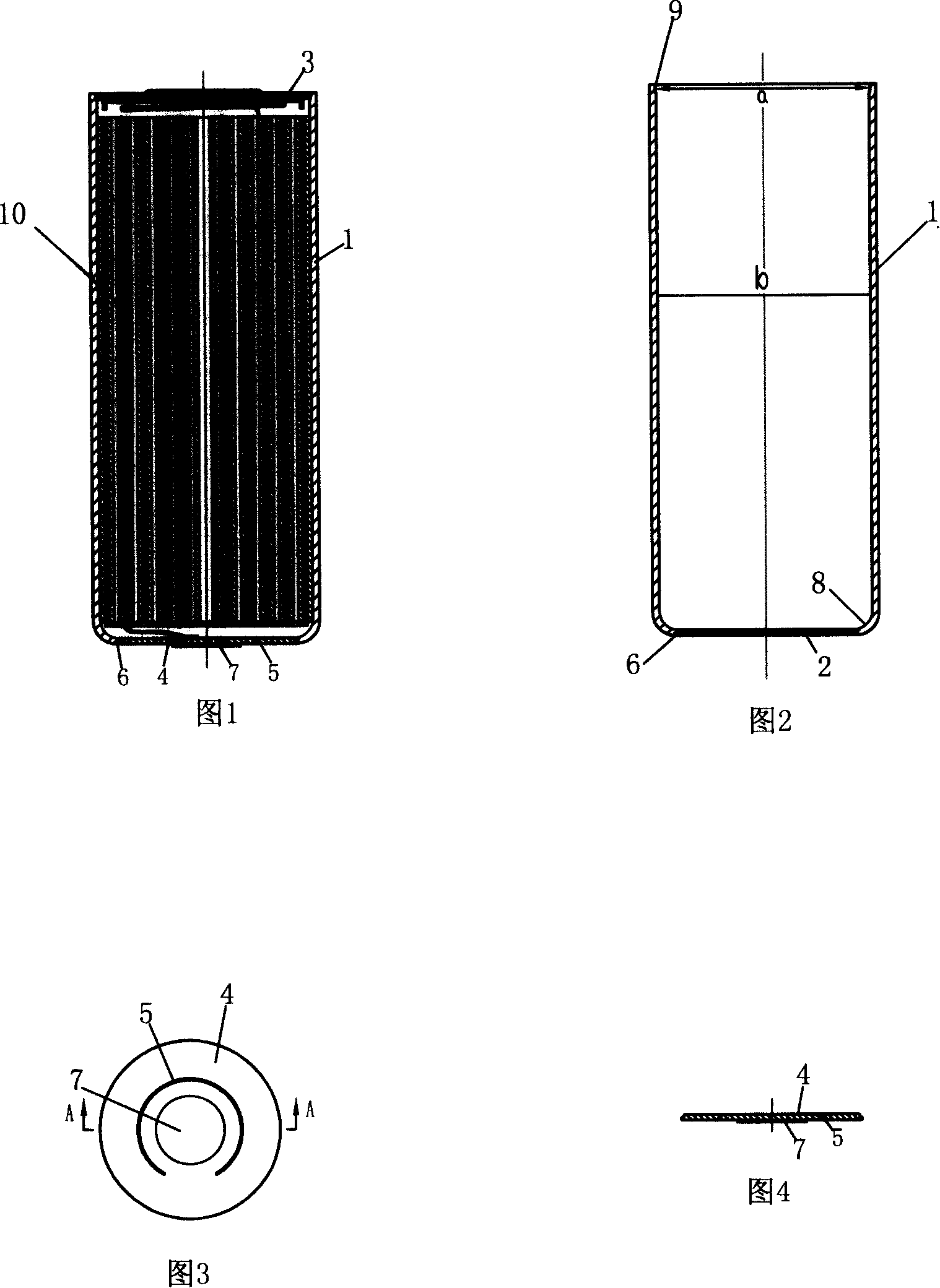

[0024] Embodiment 1: With reference to FIGS. 1 to 4, a cylindrical battery includes a cylindrical battery casing cylinder 1, a battery unit 10, an upper cover 3 and a lower cover 4. The top of the cylindrical battery case barrel 1 is open, the top of the cylindrical battery case barrel 1 is provided with a step 9 that facilitates the engagement with the upper cover 3, and the bottom of the cylindrical battery case barrel 1 has a stepped opening 2 The support table 8 is used to support the battery unit 10. The outer edge of the lower cover 4 is provided with a step 6 that matches the stepped opening 2, and the lower cover 4 is also provided for timely pressure relief and avoid battery The exploded groove 5 and the lower cover plate 4 are welded and sealed on the stepped opening 2 of the support table 8. In addition, the outer surface of the lower cover plate 4 is plated with metallic nickel 7 to facilitate the battery welding of wires. The metal nickel 7 coating can also be replace...

Embodiment 2

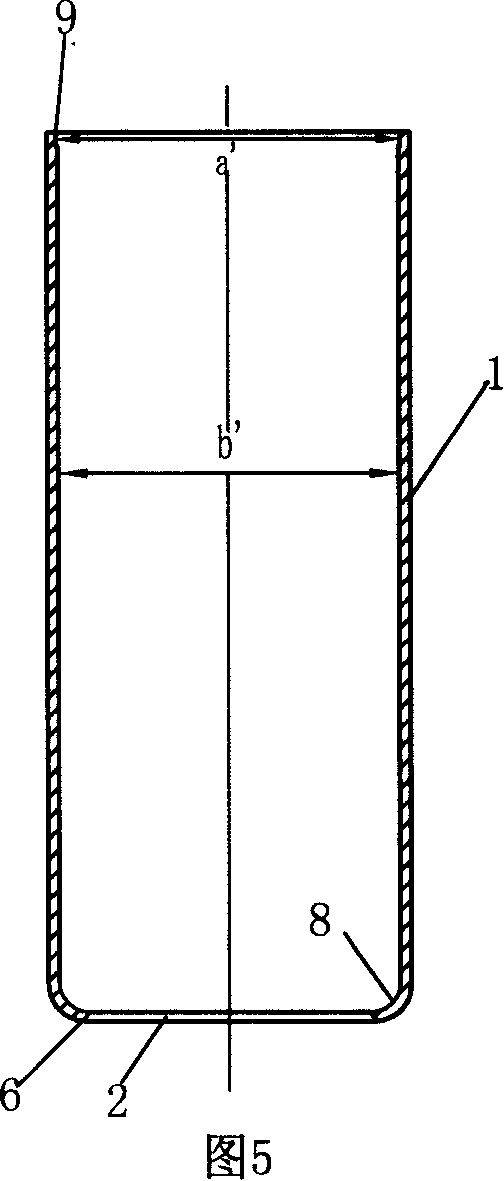

[0027] As shown in Figure 5, a cylindrical battery case. The bottom of the cylindrical battery case barrel 1 is a support table 8 with a cone-shaped opening 2. Correspondingly, the outer edge of the lower cover 4 is set to correspond to it. Cone surface 6 (not drawn).

[0028] The manufacturing method of the above-mentioned battery casing: the aluminum cylindrical battery casing barrel is formed by stamping. The stamping process includes: 1) cutting the blank from the plate into a disc shape; 2) drawing the disc-shaped blank into a bottomed cylinder of the required shape; 3) punching a through hole at the bottom of the cylinder; 4) Punching the perimeter of the through hole to form the perimeter into the desired shape, such as stepped or truncated cone. Among them, blanking and deep drawing into a bottomed cylinder are conventional processing methods. The bottom step hole is processed as follows: first punch the bottom of the bottom cylinder, then press the bottom step, and finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com