Foam sandwich cap type stiffened wallboard structure and integrated forming method

A technology of a reinforced wall panel and a molding method, which is applied in the field of composite material manufacturing, can solve the problems of easy debonding of the panel and the foam sandwich core, and many molding steps, and achieves the effects of low cost, high efficiency, and reduced manufacturing cycle and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

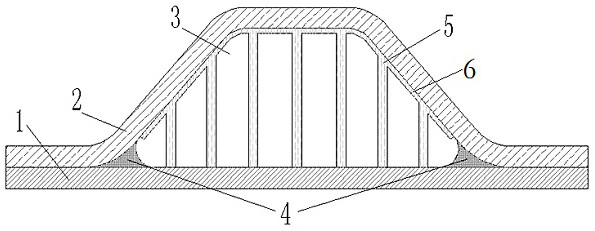

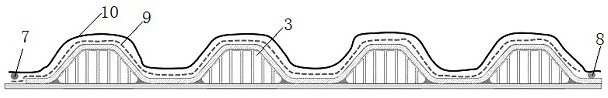

[0040] This embodiment provides a hat-shaped reinforced panel structure with a foam core, which includes an upper skin 2 , a lower skin 1 , a foam core 3 and an R-zone filling core material 4 . like figure 1 As shown, in this embodiment, the shape of the foam sandwich 3 is an isosceles trapezoid, which matches the internal shape of the hat-shaped stiffened wall panel, and is evenly distributed on the surface where the foam sandwich 3 contacts the upper skin 2 There are several criss-cross grooves 6, and at the criss-cross places of these several grooves 6, there are vertical guide holes 5 vertically penetrating through the foam sandwich core 3, and the grooves 6 and guide holes of the foam sandwich core 3 5 is filled with resin to form a resin column, the resin column is parallel to the thickness direction of the foam sandwich 3, and the resin column runs through the upper and lower surfaces of the foam sandwich 3 along the thickness direction of the foam sandwich 3, and the f...

Embodiment 2

[0043] On the basis of Example 1, this example discloses an integrated molding method for a foam-sandwich hat-shaped reinforced wall panel structure, including the following steps:

[0044] Step 1. Groove and hole processing is carried out on the upper surface of the isosceles trapezoidal foam sandwich 3, and several grooves 6 criss-crossing are formed on the upper surface of the foam sandwich 3. At the staggered positions of these several grooves 6 Provide diversion holes 5 vertically penetrating through the upper and lower surfaces of the foam sandwich core 3;

[0045] Step 2, laying the reinforcement material treated with the sizing agent on the molding tool, and pre-pumping to complete the laying of the lower skin 1;

[0046] Step 3: Position and place the slotted and perforated foam core 3 on the laid-up lower skin 1 by means of laser projection, and perform pre-pumping so that the foam core 3 and the lower skin 1 are in good condition fixed;

[0047] Step 4: Lay up the u...

Embodiment 3

[0054] On the basis of Embodiment 2, this embodiment discloses an integrated molding method for a foam sandwich hat-type reinforced wall panel structure. Preferably, the reinforcement material is selected as one of carbon fiber, glass fiber, and aramid fiber. species or several.

[0055] Preferably, the reinforcement material is continuous fiber dry fabric, including one or more of unidirectional fabric, plain weave, twill weave and satin weave.

[0056] Preferably, the main components of the sizing agent used in the molding process are unsaturated polyester, epoxy resin, novolac epoxy resin, bismaleimide phenylmethane, diallyl bisphenol A, polyamide resin, One or several types of carboxyl-terminated liquid nitrile rubber.

[0057] Preferably, the loading method of the sizing agent-loaded fabric is one or more of powder loading, solution loading, and resin film loading methods.

[0058] Preferably, the mass fraction of the sizing agent in the sizing agent-loaded fabric is 3%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com