Molding mould capable of adjusting concrete interlayer bonding thickness and test method thereof

A concrete layer and forming mold technology, which is applied in the field of highway engineering, can solve the problems of interlayer bonding performance disturbance, affecting the evaluation results of the bonding ability of the interlayer bonding material, and it is difficult to accurately control the thickness of the bonding material, so as to avoid Disturbance, easy disassembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

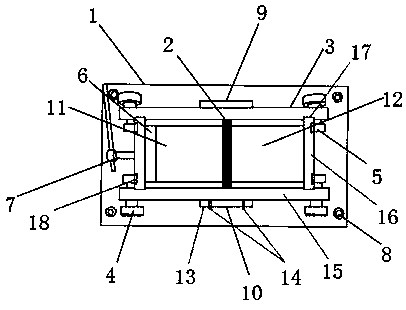

[0046] Such as figure 1 As shown, a forming mold with adjustable interlayer bonding thickness of concrete, including a base 1;

[0047] A fixed block 9 and a counter force frame 10 are respectively fixedly arranged at symmetrical positions on both sides of the base 1;

[0048] The reaction force frame 10 includes a frame body 13 fixed on the base 1 and a plurality of reaction force screws 14 arranged on the frame body 13;

[0049] A rectangular mold frame 3 is placed on the base 1; the long side frame 15 and the short side frame 16 of the rectangular mold frame 3 are detachably connected, and there is no special limitation on the specific connection method;

[0050] The rectangular mold frame 3 is provided with a thickness-adjusting steel plate 2, and the plane where the thickness-adjusting steel plate 2 is located is perpendicular to the plane where the long-side frame 15 is located; 1. The upper surface is in contact; that is, the thickness of the steel plate is adjusted. ...

Embodiment 2

[0060] Such as figure 1 As shown, a forming mold with adjustable interlayer bonding thickness of concrete includes a base 1; the base 1 is rectangular;

[0061] A fixed block 9 and a counter force frame 10 are respectively fixedly arranged at symmetrical positions on both sides of the base 1;

[0062] The reaction force frame 10 includes a frame body 13 fixed on the base 1 and a plurality of reaction force screws 14 arranged on the frame body 13;

[0063] A rectangular mold frame 3 is placed on the base 1; the long side frame 15 and the short side frame 16 of the rectangular mold frame 3 are detachably connected; specifically: both ends of the long side frame 15 are provided with first grooves 17, The two sides of the short-side frame 16 are snapped into the first grooves 17 of the two long-side frames 15 respectively;

[0064] The rectangular mold frame 3 is provided with a thickness-adjusting steel plate 2, and the plane where the thickness-adjusting steel plate 2 is locat...

Embodiment 3

[0075] Such as figure 1 As shown, a forming mold with adjustable interlayer bonding thickness of concrete includes a base 1; the base 1 is rectangular;

[0076] A fixed block 9 and a counter force frame 10 are respectively fixedly arranged at symmetrical positions on both sides of the base 1;

[0077] The reaction force frame 10 includes a frame body 13 fixed on the base 1 and a plurality of reaction force screws 14 arranged on the frame body 13;

[0078] A rectangular mold frame 3 is placed on the base 1; the long side frame 15 and the short side frame 16 of the rectangular mold frame 3 are detachably connected; specifically: both ends of the long side frame 15 are provided with through holes, and The side frame 15 is positioned at the inner side of the through hole to be provided with a first groove 17, and the two sides of the short side frame 16 are snapped into the first grooves 17 of the two long side frames 15 respectively; There are respectively provided with a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com