Preparation method of wear-resistant composite material and preparation method of wear-resistant composite material casting

A composite material and composite molding technology, which is applied in the preparation of wear-resistant composite material castings and the preparation of wear-resistant composite materials, can solve the problem of low bonding strength of the composite interface between ceramic particles and metal matrix, so as to increase thickness and improve wear resistance Performance, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

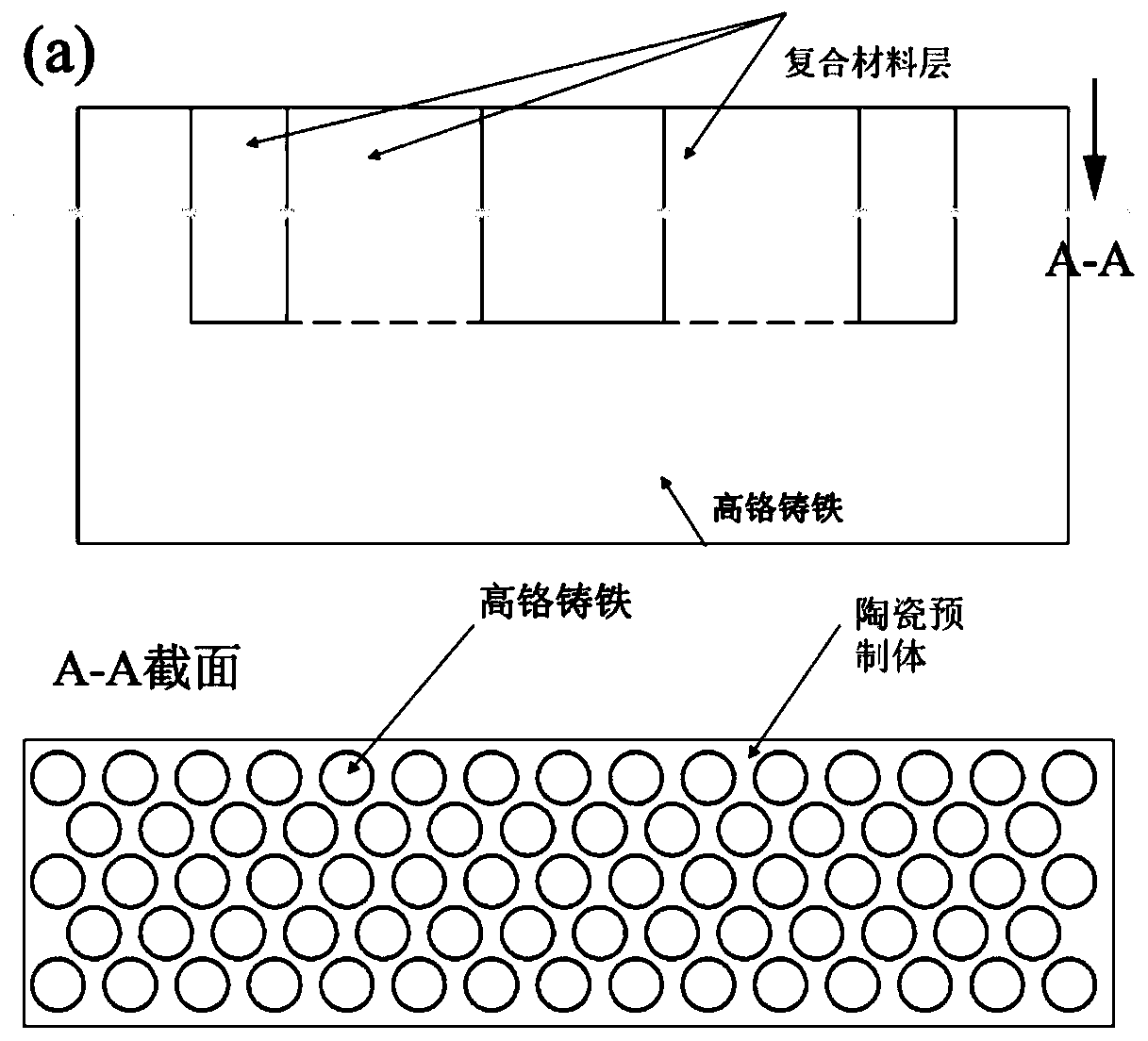

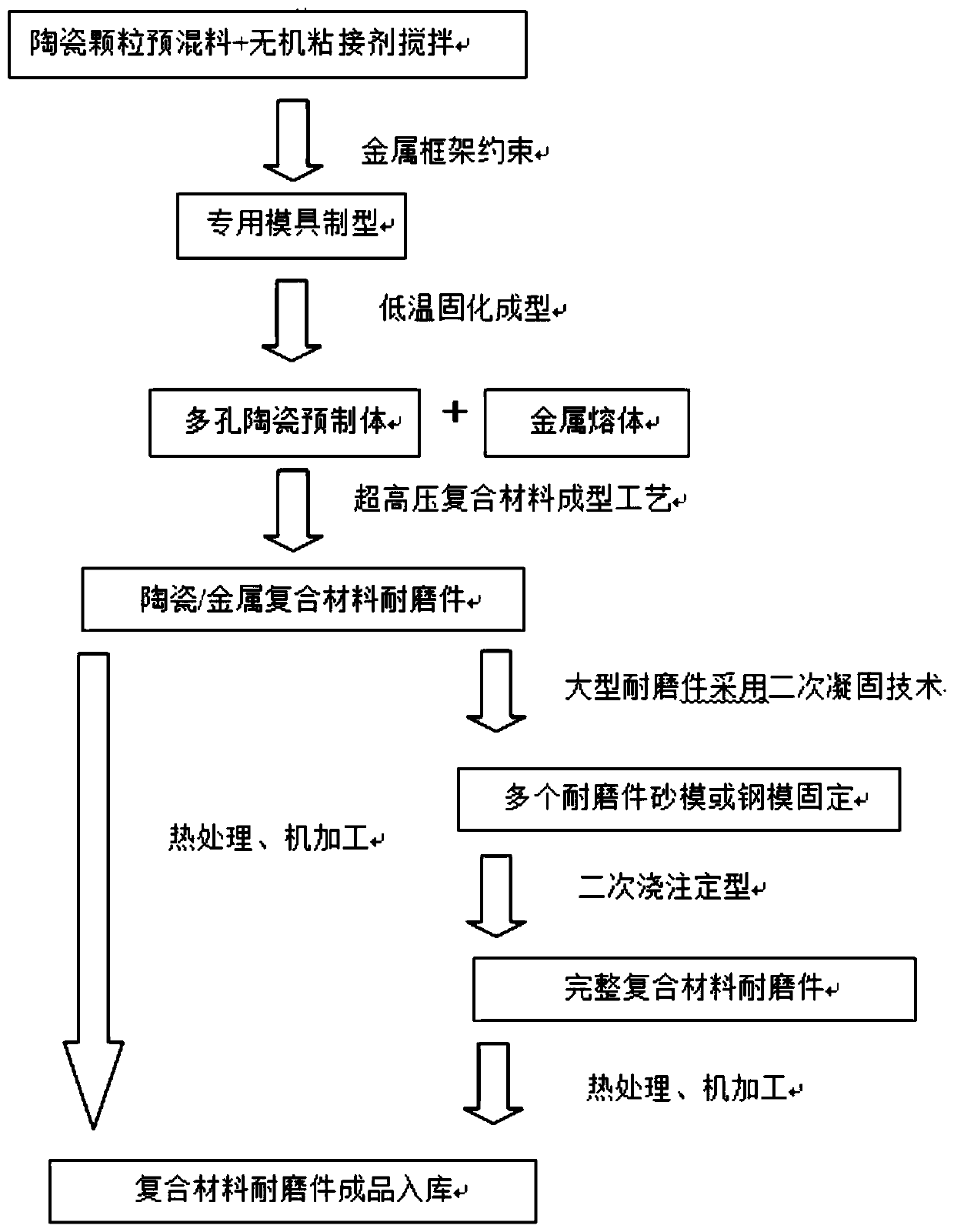

[0035] The embodiment of the present application provides a method for preparing a wear-resistant composite material, including: under the condition of a pressure of 10MPa-200Mpa, high-pressure composite molding of a metal melt and a preheated porous ceramic preform in a metal mold .

[0036] In some embodiments of the present application, the preparation step of the porous ceramic preform includes: by weight, 900-1100 parts of ceramic particles, 15-55 parts of nano-alumina powder, 0.1-1 part of nano-cerium oxide, 0.1-1 part of nano-yttrium oxide, 0.1-1 part of titanium dioxide, 0.5-5 parts of kaolin and 2.5-10 parts of silicon dioxide are fully mixed; then add 30-90 parts of liquid inorganic glue and stir and mix, and put the mixture and metal frame into the mold The porous ceramic preform is made in the

[0037] The porous ceramic preform prepared by the above method has better bonding strength, which makes the preform have better stability during the high-pressure composit...

Embodiment 1

[0051] This embodiment provides a method for preparing a wear-resistant composite material, including:

[0052] Step 1: The ceramic powder is ZTA particles, the particle size is 10 mesh, and 1000 parts of ZTA ceramic particles, 25 parts of nano-alumina powder, 1 part of nano-cerium oxide, 0.1-1 part of nano-yttrium oxide, and 1 part of titanium dioxide are prepared in parts by mass. 5 parts of kaolin, 5 parts of silica, mixed evenly, add 50 parts of liquid inorganic glue and stir well, put it into a tough metal frame, and make a porous prefabricated body in a special mold;

[0053] Step 2: Roast the porous preform at 80°C and 150°C for 2 hours respectively;

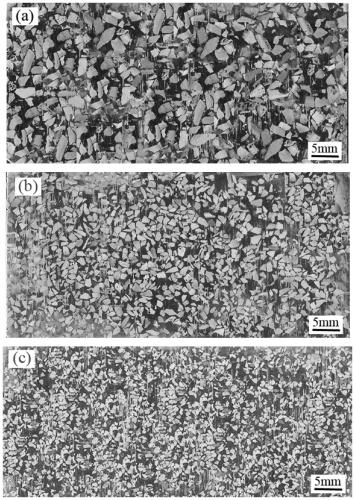

[0054] Step 3: Place the shaped and preheated porous prefabricated body in the set position of the cavity to fix it, pour an appropriate amount of metal melt, and use high-pressure composite molding technology to place the ZTA ceramic prefabricated body and high-chromium cast iron under a pressure of 120MPa High-pressure...

Embodiment 2

[0058] This embodiment provides a method for preparing a wear-resistant composite material, including:

[0059] Step 1: The ceramic powder is ZTA particles, and the particle size is 20 meshes. In parts by mass, 1000 parts of ZTA ceramic particles, 25 parts of nano-alumina powder, 1 part of nano-cerium oxide, 0.1-1 part of nano-yttrium oxide, and 1 part of titanium dioxide 1 part, 3 parts of kaolin, and 10 parts of silicon dioxide are uniformly mixed, and 40 parts of liquid inorganic glue are added and stirred thoroughly, and after being put into a tough metal frame, a porous prefabricated body is made in a special mold;

[0060] Step 2: Baking the porous preform at a high temperature of 150°C for 2 hours;

[0061] Step 3: Place the shaped and preheated porous preform in the set position of the cavity and fix it, pour an appropriate amount of metal melt, and use the high-pressure composite molding process to place the ZTA ceramic preform and high-chromium cast iron under a pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com