Hot-rolled steel sheet and manufacturing method therefor

A technology of hot-rolled steel plate and manufacturing method, which is applied in the direction of manufacturing tools, heat treatment furnaces, heat treatment equipment, etc., can solve problems such as cracking, unsuitable running parts, poor hole expansion, etc., and achieve improved fuel efficiency, shortened processing procedures, and reduced manufacturing costs. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

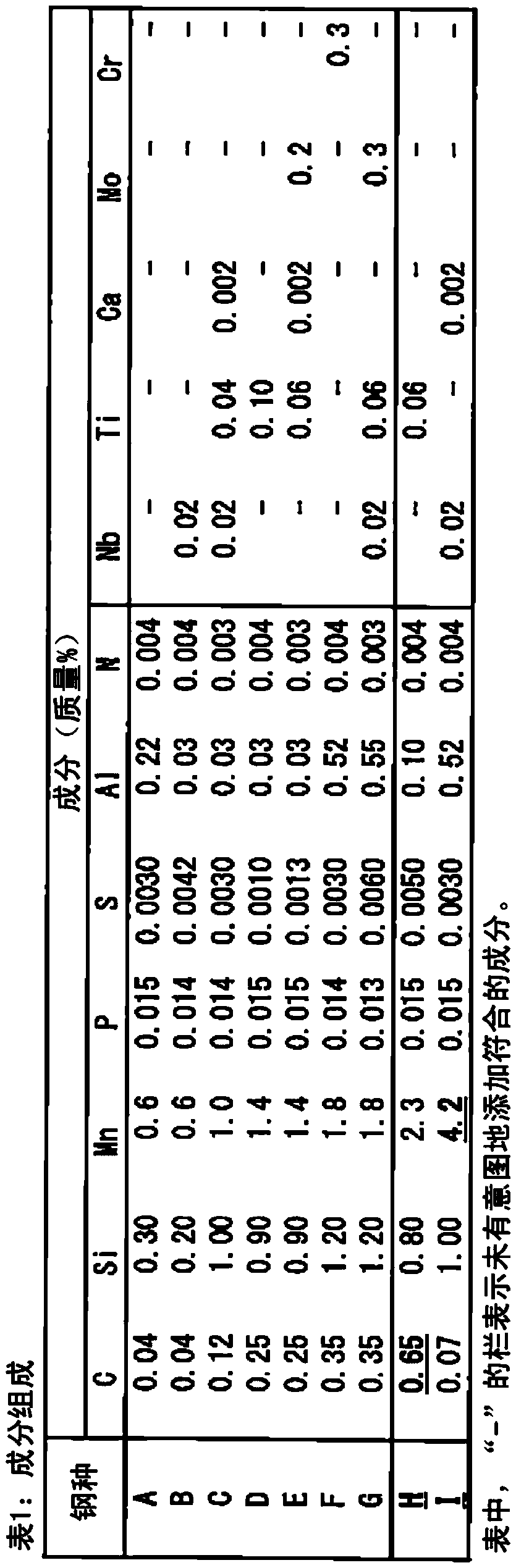

[0102] The steel containing the composition shown in Table 1 is cast using continuous equipment from casting to rolling. After casting a slab, rough rolling and finish rolling are performed, followed by primary cooling, intermediate air cooling and secondary cooling, and coiling. Taken, a hot-rolled steel sheet was produced. The rest other than the components shown in Table 1 are Fe and impurities. In addition, the component composition obtained by analyzing the sample collected from the produced hot-rolled steel sheet was equivalent to the component composition of the steel shown in Table 1.

[0103]

[0104]

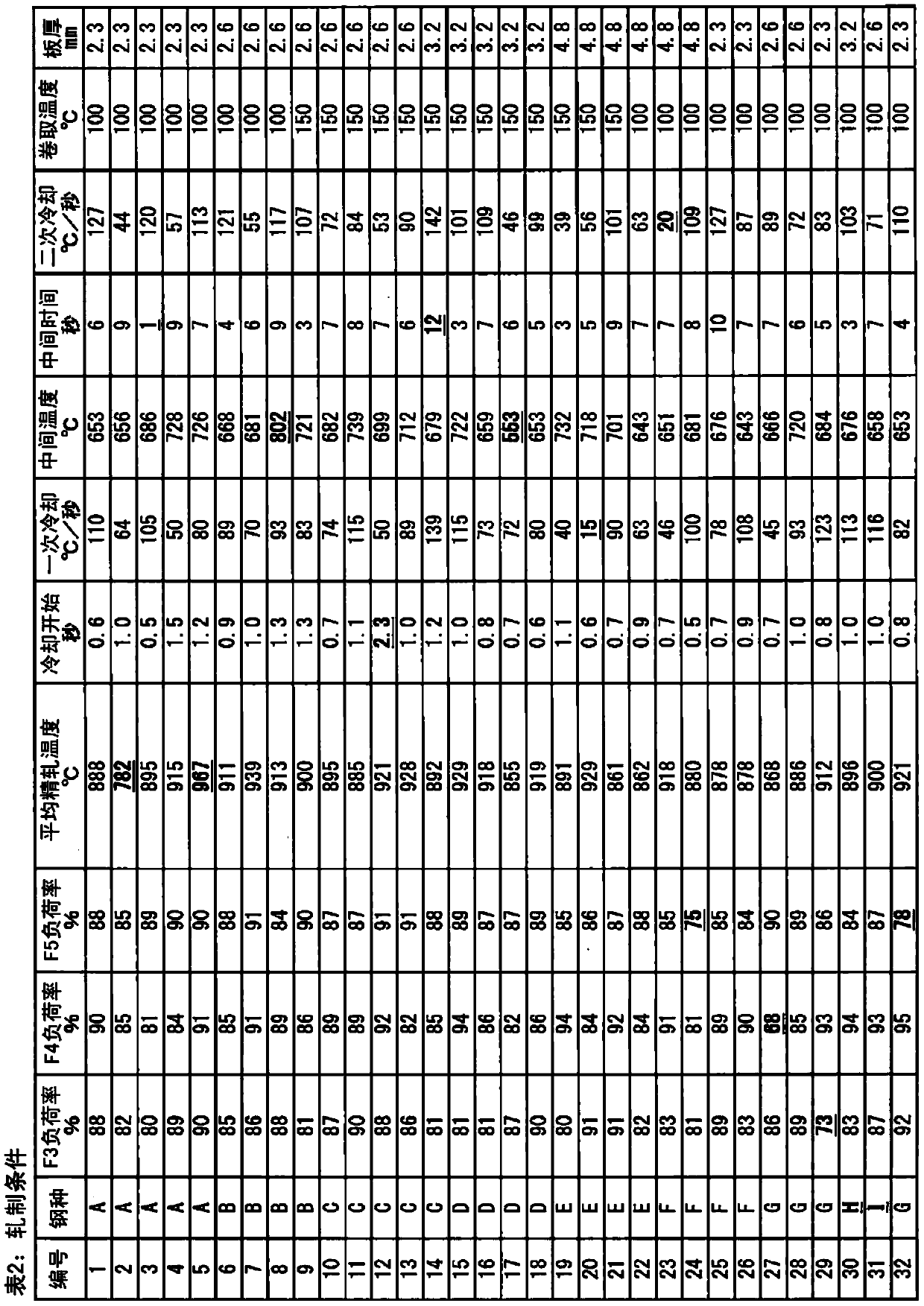

[0105] Table 2 shows the codes of the steel types used, the finish rolling conditions, and the thicknesses of the steel sheets. In Table 2, "F3 load factor", "F4 load factor" and "F5 load factor" refer to the respective rolling loads of the last three rolling stands in the rolling mill having five consecutive finishing stands The ratio of the rolling load to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com