Preparation method of material and/or color gradient mobile phone shell

A mobile phone shell and color gradient technology, applied in the direction of additive processing, telephone structure, etc., can solve the problems of weak bonding, separation of metal and plastic, etc., achieve the effect of reducing electromagnetic shielding interference, increasing bonding strength, and achieving a smooth transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

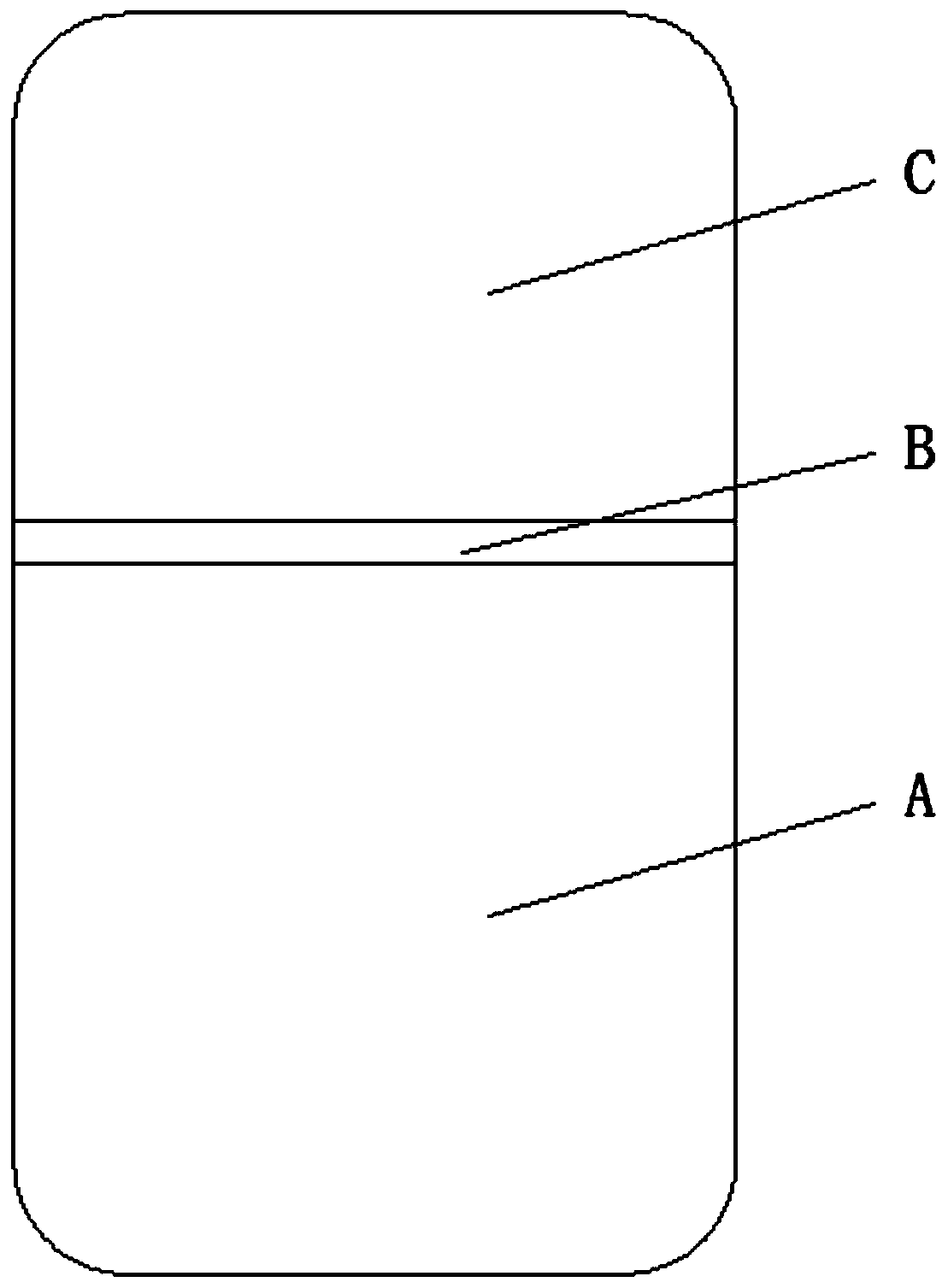

[0021] See figure 1 , the present invention comprises the following steps:

[0022] S1, prepare 316 stainless steel feeding material and black zirconia ceramic feeding material for 3D printing according to the 3D printing model; the preparation steps of 316 stainless steel feeding material and black zirconia ceramic feeding material are: 316 stainless steel powder and zirconia ceramic feeding material The powder was mixed with POM / PP in a mixer for 3 hours, and granulated by a granulator to prepare 316 stainless steel feed and zirconia ceramic feed;

[0023] S2. Green printing of mobile phone shell: According to the distribution of materials in the 3D printing model, it is divided into antenna printing area C and main body printing area A; 316 stainless steel feeding material and black zirconia ceramic feeding material are added to the 3D printing equipment with multiple hoppers , the device is a 3D printer with multi-input and single-out (that is, with multiple feeding tubes...

Embodiment 2

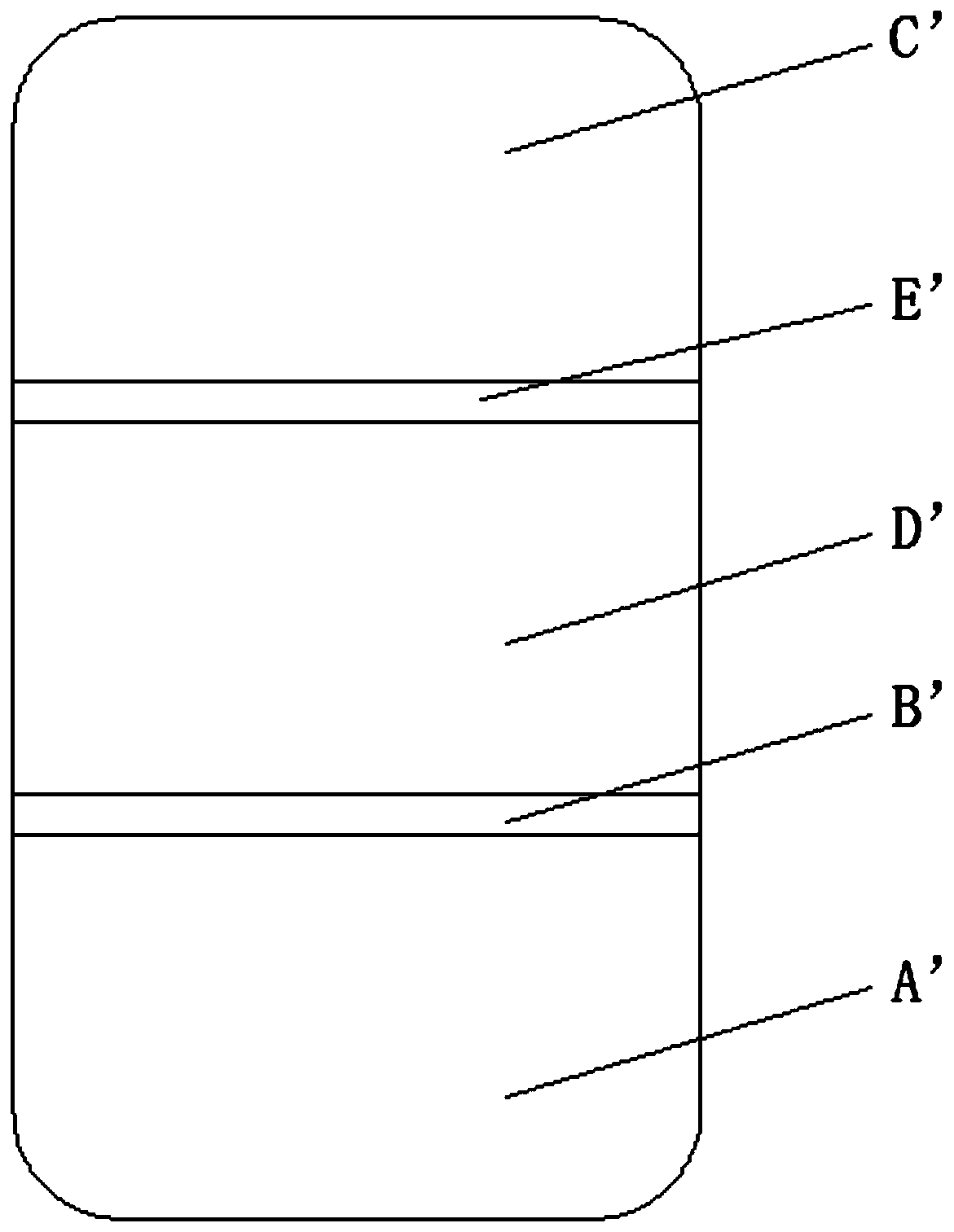

[0031] See figure 2 , the present invention comprises the following steps:

[0032] S1. Prepare 316 stainless steel feedstock, black zirconia ceramic feedstock and white alumina ceramic feedstock for 3D printing according to the 3D printing model; 316 stainless steel feedstock, black zirconia ceramic feedstock and white alumina ceramic feedstock The preparation steps of the ceramic feed are as follows: 316 stainless steel powder, zirconia ceramic powder and alumina ceramic powder are mixed with POM / PP in a mixer for 3 hours, and the granulator is granulated to prepare 316 stainless steel feed, oxidized Zirconium ceramic feed and alumina ceramic feed;

[0033] S2. Green printing of mobile phone shell: According to the distribution of materials in the 3D printing model, it is divided into antenna printing area C', main body printing area A' and main body printing area D'; feed 316 stainless steel, zirconia ceramics and alumina ceramics Feeding is added to a 3D printing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com