Integrated forming method of super-hybrid panel/three-dimensional woven hollow interlayer composite material

A technology of three-dimensional weaving and composite materials, which is applied in the field of preparation and molding of sandwich structures, can solve the problems of non-uniform standing height and incomplete standing of three-dimensional weaving hollow prefabricated fleece, and achieve the effect of high molding efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The cutting size of the first step is one piece of 1000mm×1200mm×15mm glass three-dimensional woven hollow prefabricated body, eight pieces of 1000mm×1200mm×0.15mm glass fiber reinforced epoxy prepreg, eight pieces of 1000mm×1200mm×0.03mm epoxy hot melt adhesive film .

[0036] The second step is to perform surface treatment on four 2024 aluminum alloy sheets with a size of 1000mm×1200mm×0.3mm, by sandblasting and 15 minutes of oxygen plasma surface treatment.

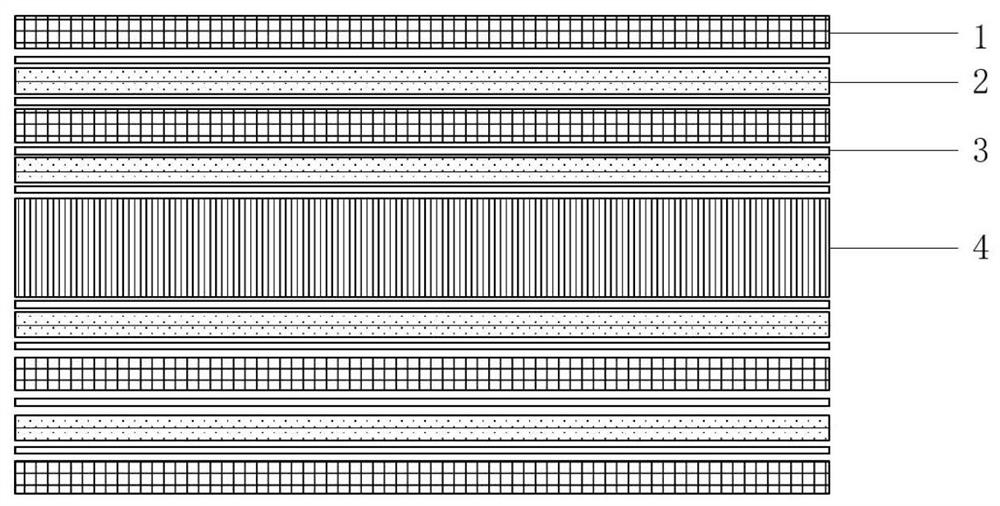

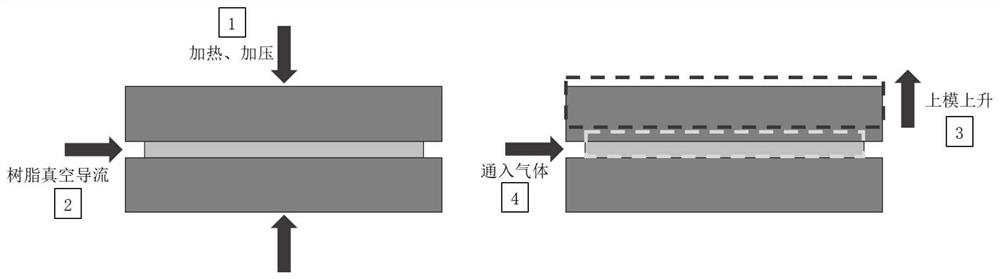

[0037] Step 3 Reference figure 1 , the materials are divided into 2024 aluminum alloy sheet 1, glass fiber prepreg 2, 2024 aluminum alloy sheet 1, glass fiber prepreg 2, glass three-dimensional woven hollow prefabricated body 4, glass fiber prepreg 2, 2024 aluminum alloy sheet 1 1. Glass fiber prepreg 2. 2024 aluminum alloy sheet 1, wherein the layers are bonded by epoxy hot melt adhesive film, and the glass fiber prepreg is cross-laminated.

[0038]The fourth step is to stick the double-sided bonded release c...

Embodiment 2

[0043] The first step is to cut out one piece of 800mm×1000mm×10mm carbon three-dimensional braided hollow prefabricated body, eight pieces of 800mm×1000mm×0.3mm carbon fiber reinforced polypropylene prepreg, and eight pieces of 800mm×1000mm×0.04mm polypropylene hot-melt adhesive film.

[0044] The second step is to carry out surface treatment on four 6061 aluminum alloy sheets with a size of 800mm×1000mm×0.5mm, by sandblasting and 15 minutes of oxygen plasma surface treatment.

[0045] The third step is to use the manipulator to press the material into 6061 aluminum alloy sheet, carbon fiber prepreg, 6061 aluminum alloy sheet, carbon fiber prepreg, carbon three-dimensional woven hollow prefabricated body, carbon fiber prepreg, 6061 aluminum alloy sheet, carbon fiber prepreg, 6061 aluminum alloy sheet, in which the layers are bonded with polypropylene hot-melt adhesive film, and the carbon fiber prepreg is cross-laminated.

[0046] The fourth step is to stick the double-sided ...

Embodiment 3

[0051] Step 1 The cutting size is 600mm×1100mm×15mm, one piece of basalt three-dimensional braided hollow prefabricated body, eight pieces of 600mm×1100mm×0.3mm basalt reinforced polyamide prepreg, and eight pieces of 600mm×1100mm×0.05mm polyamide hot-melt adhesive film.

[0052] The second step is to carry out surface treatment on four 7075 aluminum alloy sheets with a size of 600mm×1100mm×0.5mm, by sandblasting and 15 minutes of oxygen plasma surface treatment.

[0053] In the third step, the materials are divided into 7075 aluminum alloy sheet, basalt fiber prepreg, 7075 aluminum alloy sheet, basalt fiber prepreg, basalt three-dimensional braided hollow prefabricated body, basalt fiber prepreg, 7075 aluminum alloy sheet, basalt fiber prepreg Material, 7075 aluminum alloy sheet, in which polyamide hot-melt adhesive film is used to bond between layers, and basalt fiber prepreg is cross-laminated.

[0054] The fourth step is to stick the double-sided adhesive release cloth to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com