Bipolar plate assembly, manufacturing process, cell stack and fuel cell vehicle

A bipolar plate and component technology, applied in fuel cells, fuel cell parts, power system fuel cells, etc., can solve problems such as high production costs, easy displacement of sealing rings, and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

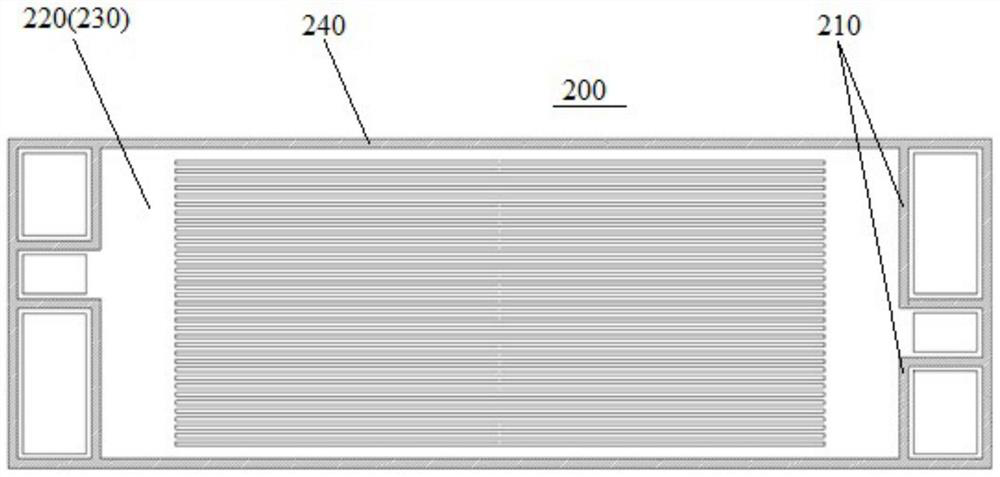

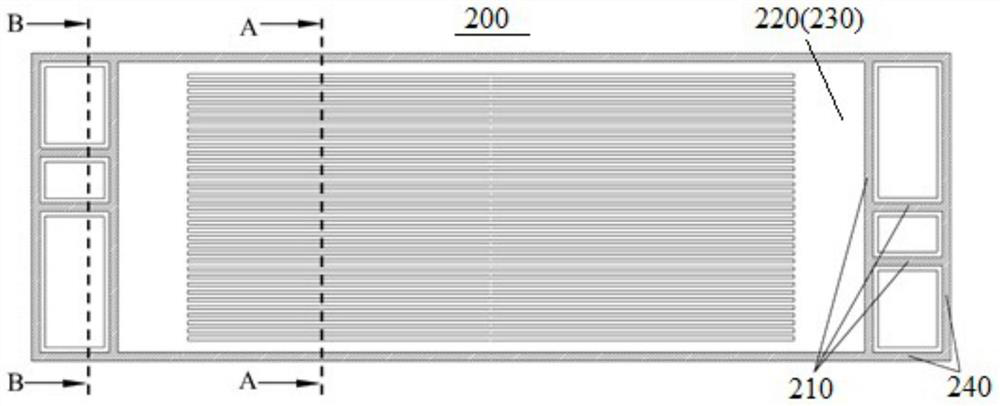

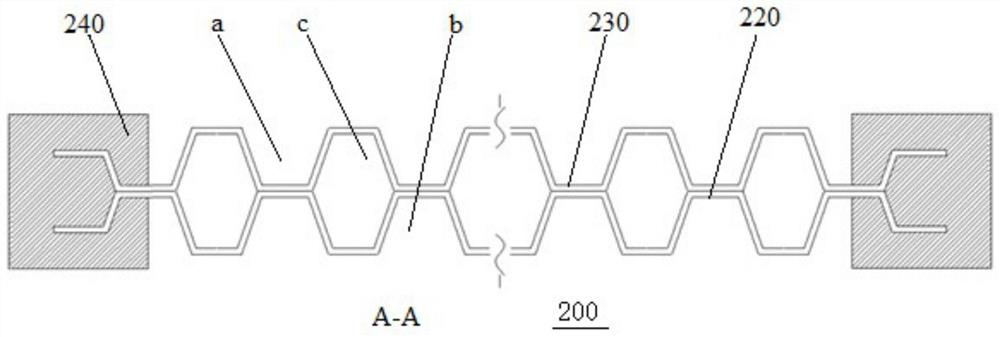

[0044] The embodiment of the present invention provides a bipolar plate assembly 200, which is different from the bipolar plate in the prior art that only includes a cathode plate and an anode plate that are not connected, see Figure 1 to Figure 4 The bipolar plate assembly 200 provided in this embodiment includes a cathode plate 220, an anode plate 230 and a sealing assembly. The cathode plate 220 and the anode plate 230 are bonded with the opening of the flow channel 110 facing each other and connected as a whole through the sealing assembly. The sealing of the bipolar plates mainly includes the sealing of the water field c between the cathode plate 220 and the anode plate 230, and the sealing between the cathode and anode plates and the membrane electrodes, so as to prevent hydrogen and air blow-by from causing safety hazards. The sealing assembly not only plays the role of sealing the hydrogen field a, air field b and water field c, but also plays the role of "welding wire...

Embodiment 2

[0064] Based on the same inventive concept, this embodiment provides a manufacturing process for manufacturing the bipolar plate assembly 200 of the first embodiment above.

[0065] see Figure 1 to Figure 5 , the manufacturing process includes the following steps:

[0066] Stamping process: stamping and forming flow channel 110, sealing groove 120 and accommodating cavity 260 on the base material, opening injection molding process hole 130 in the groove wall of sealing groove 120, and obtaining cathode plate 220 and anode plate 230.

[0067] Specifically, in this embodiment, the base material is a pre-coated metal plate, and the stamping of the sealing groove 120 and the housing cavity 260 and the punching of the injection molding hole 130 are simultaneously completed during the stamping process of the runner 110 . Then enter the sealing process.

[0068] Sealing process: attach the cathode plate 220 and the anode plate 230 with the opening of the flow channel 110 facing ea...

Embodiment 3

[0072] Based on the same inventive concept, this embodiment provides an electric stack. A typical electric stack structure sequentially includes an intake end plate, an intake end insulation plate, an intake end collector plate, a repeating unit, a blind end collector plate, a blind end End insulation plate, blind end end plate. The whole stack is fixed by the stack fasteners, and the end plates at both ends provide a certain pressure to the repeating unit, so that the sealing ring is deformed under pressure to achieve a good sealing effect.

[0073] see Figure 6 , in the electric stack provided in this embodiment, at least one bipolar plate assembly 200 of the above-mentioned embodiment 1 is arranged in the repeating unit, so the electric stack provided in this embodiment has all the advantages of the above-mentioned embodiment 1. For other unspecified structures of the electric stack in this embodiment, reference may be made to relevant publications in the prior art, and n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com