A comprehensive processing machine

A technology of comprehensive processing and workpiece, applied in metal processing equipment, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of difficult to achieve complex component forming and actual production applications, to save work space, expand capacity, improve geometry The effect of precision and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

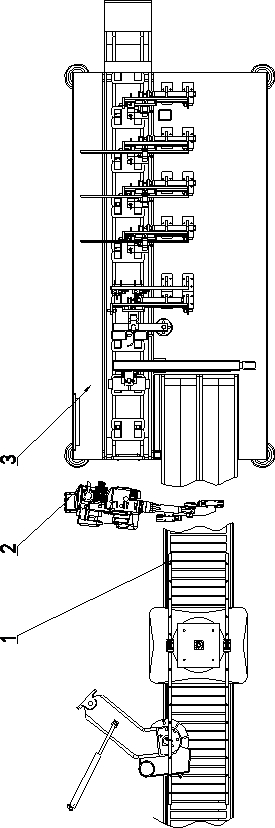

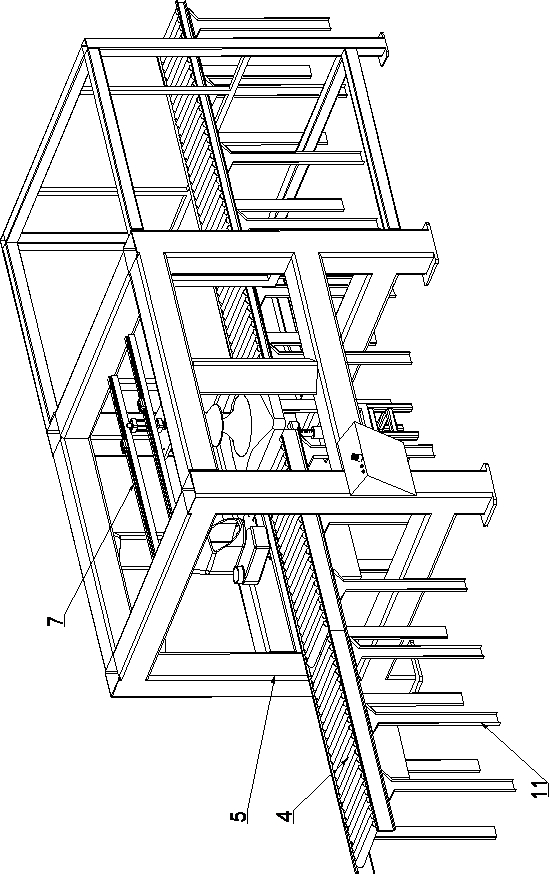

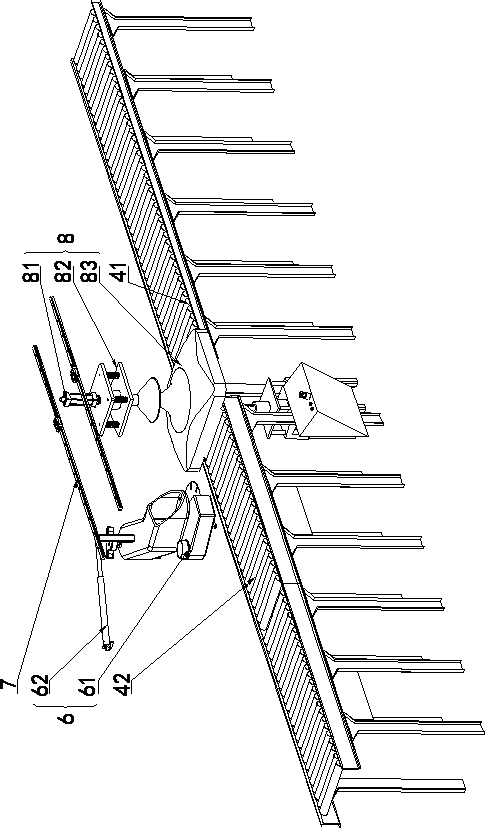

[0029] Such as Figure 1-7 A comprehensive processing machine is shown, which includes a subtractive processing module 1, an allocation control module 2, and an additive manufacturing module 3 arranged in sequence along the workpiece conveying direction; the subtractive processing module 1 includes a frame 11 and a The cutting device on the frame 11; the additive manufacturing module 3 includes a workbench 31 and a welding device arranged on the workbench 31; The batching device to the additive manufacturing module 3; also includes a numerical control module; the numerical control module includes a display unit, a control unit, a contour detection unit for monitoring the shape change trend of the workpiece in the process of adding and subtracting materials, and a contour detection unit for monitoring the increase and decrease of materials The ultrasonic micro-forging unit for internal defects of the workpiece in the process and the molten pool monitoring unit for detecting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com