Additive manufacturing method of lightweight rigid-flexible coupled heterostructure

A technology of additive manufacturing and heterogeneous structure, applied in the direction of manufacturing tools, additive manufacturing, additive processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

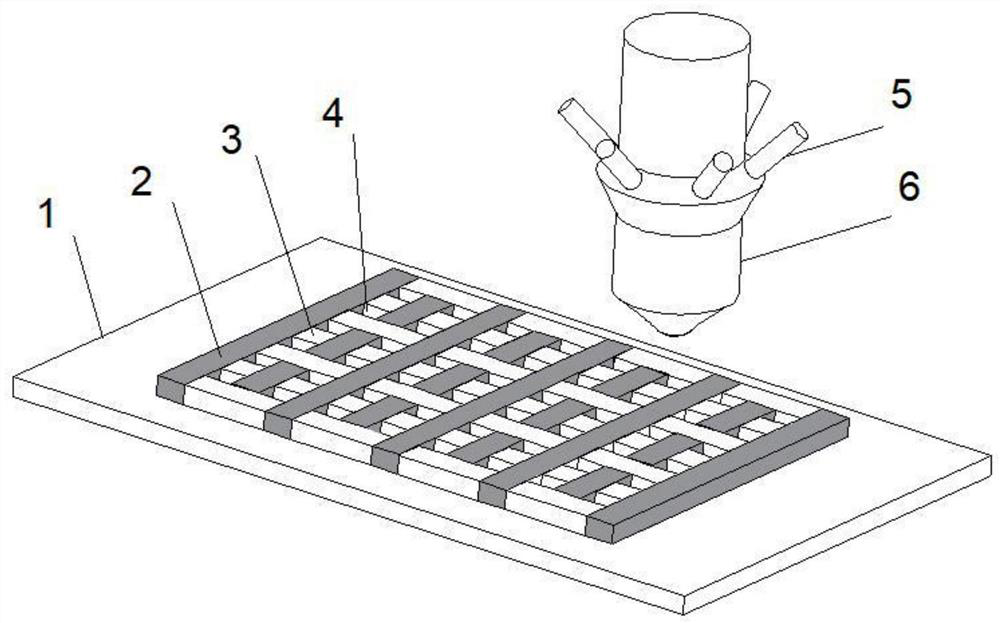

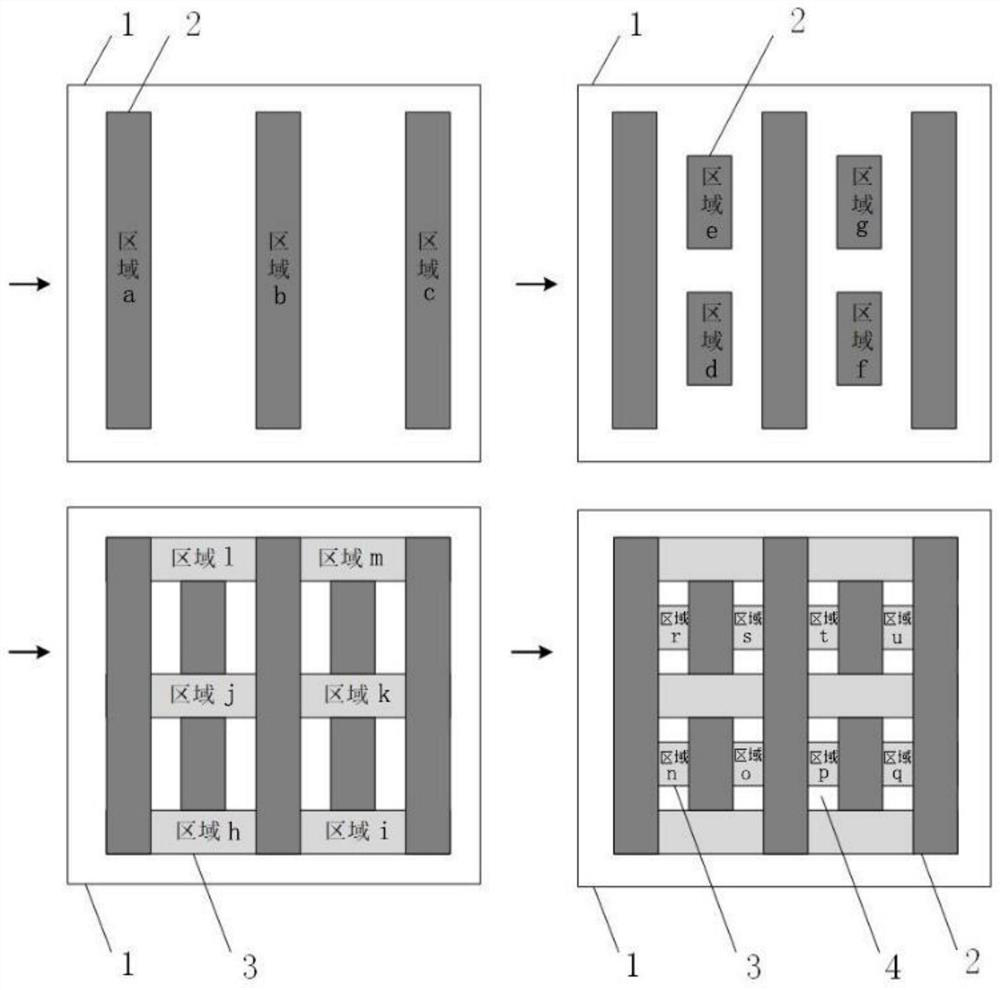

[0049] A method for additive manufacturing of a lightweight rigid-flexible coupling heterogeneous structure, comprising the following steps:

[0050] (1) According to the intermiscibility and soft-hard difference characteristics of materials, martensitic steel powder is selected as the raw material of hard material 2 in the structure, and austenitic steel powder is used as the raw material of soft material 3 in the structure, and the martensitic steel is The particle size of the powder and austenitic steel powder is 40-100μm, and the sphericity is good. The powder is dried before additive manufacturing and put into a vacuum drying furnace to increase the fluidity of the powder;

[0051] (2) The substrate 1 is made of martensitic steel plate, and the substrate 1 is processed into a suitable size by using a wire electric discharge machine, and the surface of the substrate 1 is polished with sandpaper, and the substrate 1 is polished with 400 mesh, 800 mesh and 1200 mesh sandpaper...

Embodiment 2

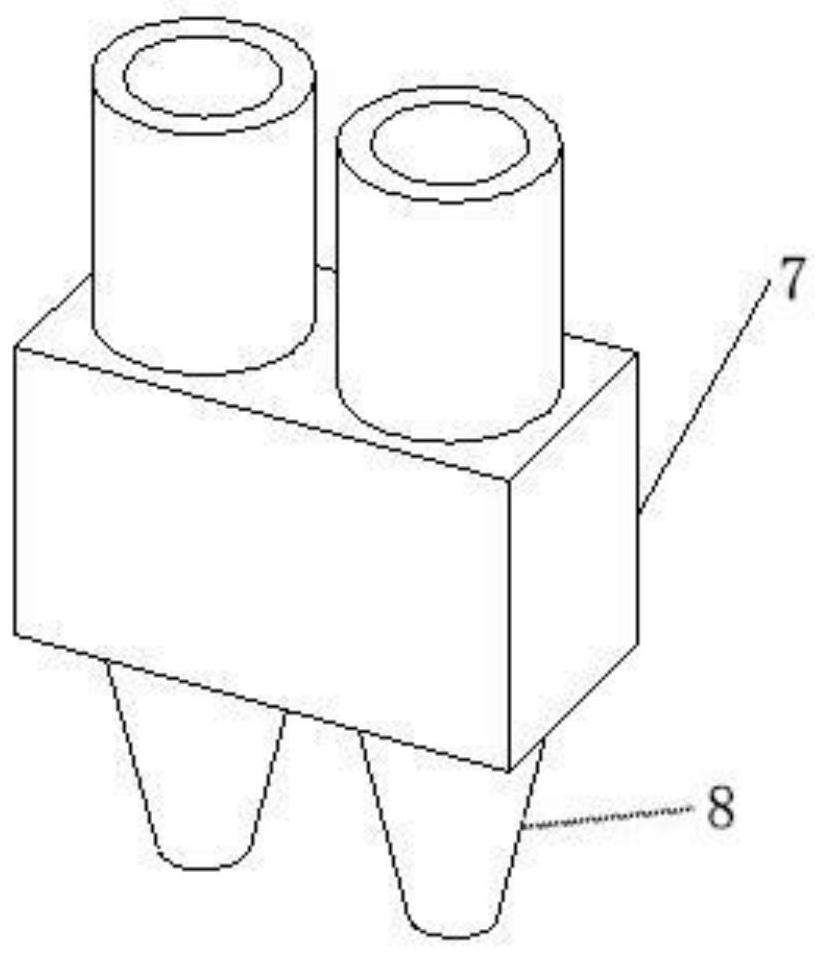

[0058] A method for additive manufacturing of a lightweight rigid-flexible coupling heterogeneous structure, comprising the following steps:

[0059] (1) According to the compatibility of materials and the characteristics of soft and hard differences, ABS thermoplastic wire is selected as the raw material of the hard material 2 in the structure, and TPU thermoplastic wire is used as the raw material of the soft material 3 in the structure. The diameter of the ABS thermoplastic filament and the diameter of the TPU thermoplastic filament should not exceed the allowable size of the throat of the fusion deposition fuse nozzle 7, the diameter of the ABS thermoplastic filament and the TPU thermoplastic filament The diameters of the ABS and TPU thermoplastic wires are 1.75mm respectively. If the diameters of the ABS thermoplastic wire and the TPU thermoplastic wire are too large, the wire cannot be fed, and if it is too small, the gears in the wire feeding device cannot be clamped and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com