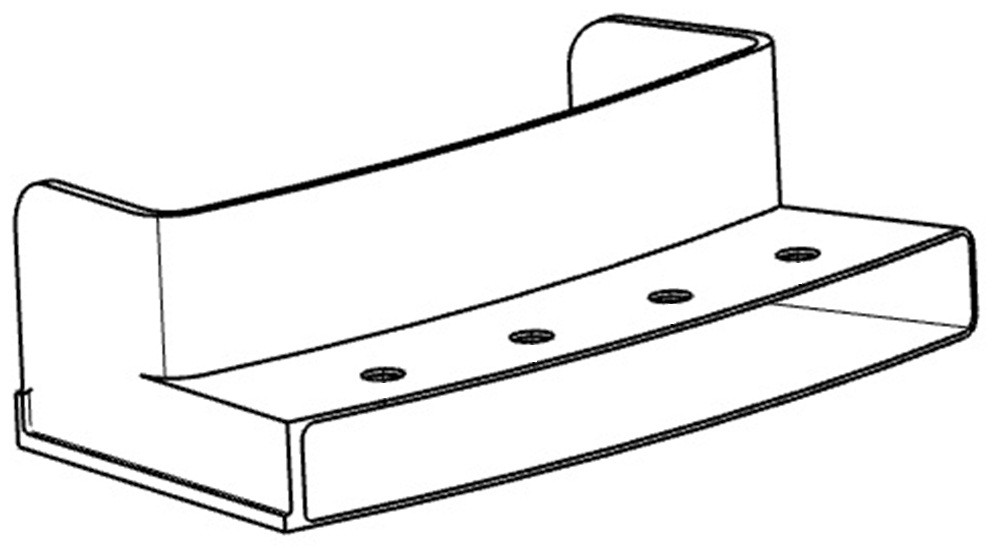

Method for manufacturing GH5188 engine heat screen through selective laser melting technology

A GH5188, laser selective melting technology, applied in the direction of additive manufacturing, improvement of process efficiency, improvement of energy efficiency, etc., can solve the problems of high scrap rate, long processing procedure, complex and lightweight structure of heat shield parts, etc., to reduce Number of welds, avoidance of weld cracking, effects of solving internal defect problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The method of preparing the GH5188 engine heat shield by laser selective melting technology is implemented according to the following steps:

[0027] Step 1, model processing: Use UG software and Magics software to add margins, select placement methods, add supports, and slice according to the thickness of 0.03mm on the 3D model of the heat shield parts. During the slices, set the heat shield parts separately After the laser power, scanning speed, scanning mode, scanning distance, powder layer thickness, and spot compensation of the entity, the outer contour of the heat shield part and the support, output the .Stl format file and process parameter file, and wait for input into the laser selective melting forming equipment;

[0028] In step 1, the heat shield parts are placed at an angle of 45° with the substrate to ensure the final forming accuracy of the heat shield parts and facilitate the removal of supports. Add 1mm of grinding and machining allowance; use Magics so...

Embodiment 2

[0046] The method of preparing the GH5188 engine heat shield by laser selective melting technology is implemented according to the following steps:

[0047] Step 1, model processing: Use UG software and Magics software to add margin, select placement mode, add support, and slice according to the thickness of 0.04mm on the 3D model of heat shield parts. During the slice, set the heat shield parts respectively After the laser power, scanning speed, scanning mode, scanning distance, powder layer thickness, and spot compensation of the entity, the outer contour of the heat shield part and the support, output the .Stl format file and process parameter file, and wait for input into the laser selective melting forming equipment;

[0048] In step 1, the heat shield parts are placed at an angle of 45° with the substrate to ensure the final forming accuracy of the heat shield parts and facilitate the removal of supports. Add 1.5mm of grinding and machining allowance; use Magics software...

Embodiment 3

[0066] The method of preparing the GH5188 engine heat shield by laser selective melting technology is implemented according to the following steps:

[0067] Step 1, model processing: Use UG software and Magics software to add allowances, select placement methods, add supports, and slice according to the thickness of 0.05mm on the 3D model of the heat shield parts. During the slices, set the heat shield parts separately After the laser power, scanning speed, scanning mode, scanning distance, powder layer thickness, and spot compensation of the entity, the outer contour of the heat shield part and the support, output the .Stl format file and process parameter file, and wait for input into the laser selective melting forming equipment;

[0068] In step 1, the heat shield parts are placed at an angle of 45° with the substrate to ensure the final forming accuracy of the heat shield parts and facilitate the removal of supports. Add 2mm of grinding and machine allowance; use Magics s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com