Investment casting production technology of valve casting, and valve casting

A technology of investment casting and production process, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of thin-walled structure of castings, and achieve the effect of good surface finish, good internal quality, and increased solidification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

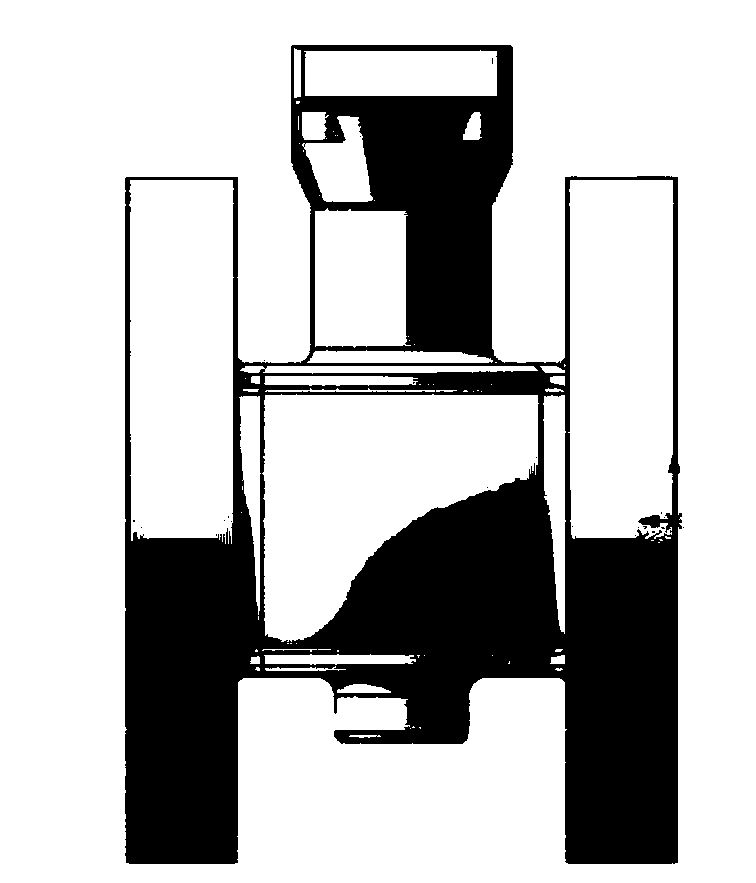

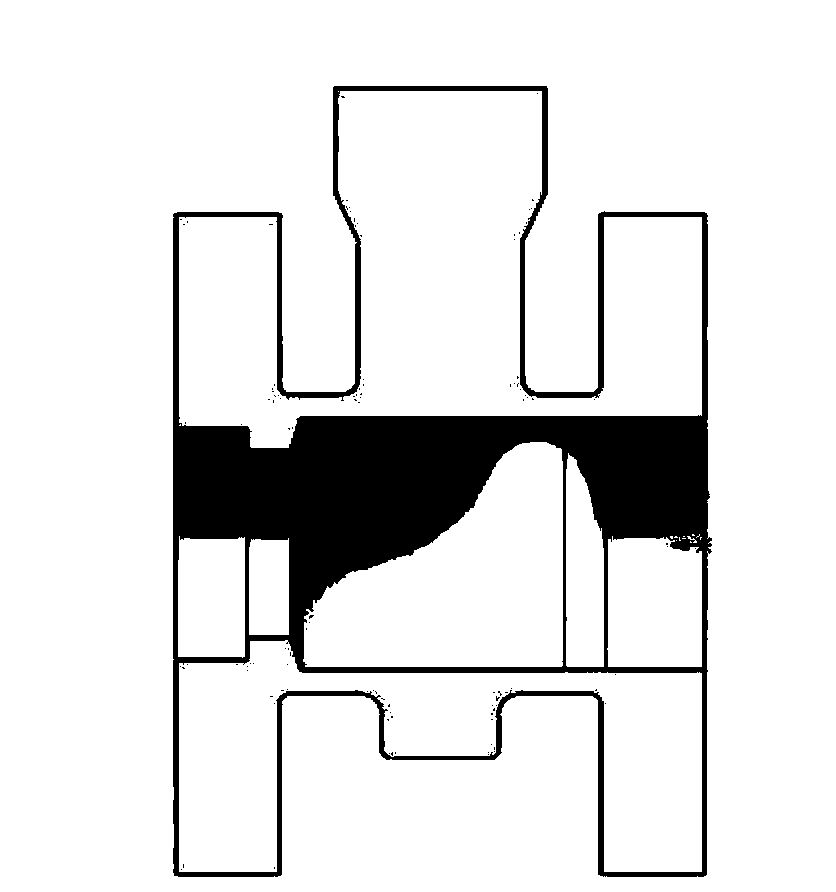

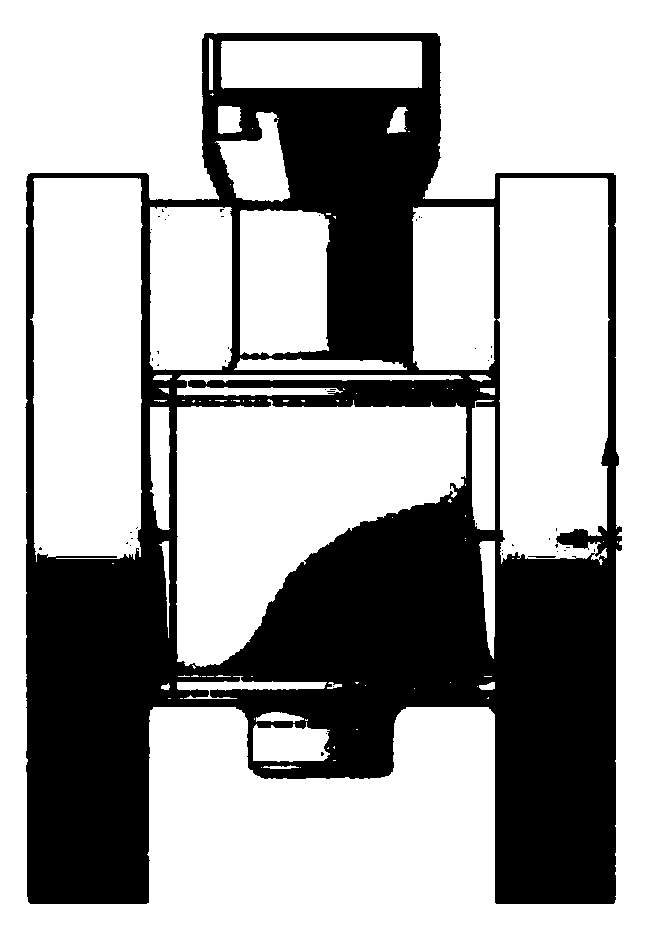

Image

Examples

Embodiment 1

[0029] A production process of investment casting of valve castings, comprising the steps of:

[0030] Step 1. Wax mold process: put the wax into the wax injection machine, and inject the wax in the wax injection machine to form a wax piece. The pressure of the wax injection is 20kg / cm 2 , the temperature of the wax injection process workshop is 22°C, and the wax pieces are cooled and then blown dry. After the surface of the wax tree is qualified, the wax model is ready for use;

[0031] Step 2. Shell making process: use the silica sol shell making process to make a shell on the wax model in step 1 by dipping slurry, sticking sand and drying cycle. The drying temperature is 80°C and the drying time is 6 hours. Keep the inner cavity dry during the shell making process, and there is no accumulation in the cavity when coating and hanging. After the shell making is completed, drill holes. Dewaxing is carried out in the middle, and the vapor pressure of dewaxing is 8.0kg / cm 2 Af...

Embodiment 2

[0038] A production process of investment casting of valve castings, comprising the steps of:

[0039] Step 1. Wax mold process: put the wax into the wax injection machine, and inject the wax in the wax injection machine to form a wax piece. The pressure of the wax injection is 20kg / cm 2 , the temperature of the wax injection process workshop is 28°C, the wax pieces are cooled and then blown dry, the cooling medium of the wax pieces is water, the cooling temperature is 30°C, and the cooling time is 50min, then the wax is repaired, and the tree is assembled and inspected after passing the inspection After the surface of the wax tree is qualified, the wax model is ready for use;

[0040] Step 2. Shell making process: use the silica sol shell making process to make a shell on the wax model in step 1 by dipping slurry, sticking sand and drying cycle. The drying temperature is 100 °C and the drying time is 4 hours. Keep the inner cavity dry during the shell making process, and the...

Embodiment 3

[0047] A production process of investment casting of valve castings, comprising the steps of:

[0048] Step 1. Wax mold process: put the wax into the wax injection machine, and inject the wax in the wax injection machine to form a wax piece. The pressure of the wax injection is 20kg / cm 2 , the temperature of the wax injection process workshop is 25°C, the wax pieces are cooled and then blown dry, the cooling medium of the wax pieces is water, the cooling temperature is 25°C, and the cooling time is 60min, then the wax is repaired, and the tree is assembled and inspected after passing the inspection After the surface of the wax tree is qualified, the wax model is ready for use;

[0049] Step 2. Shell making process: use the silica sol shell making process to make a shell on the wax model in step 1 by dipping slurry, sticking sand and drying cycle. The drying temperature is 90 ° C and the drying time is 5 hours. Keep the inner cavity dry during the shell making process, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com