Composite material integrated frame beam and manufacturing method

A technology of composite materials and manufacturing methods, applied in the direction of fuselage frame, fuselage, transportation and packaging, etc., can solve problems such as manufacturing difficulties, delamination risks, and inability to guarantee strength, so as to reduce weight, avoid delamination, and reduce parts Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

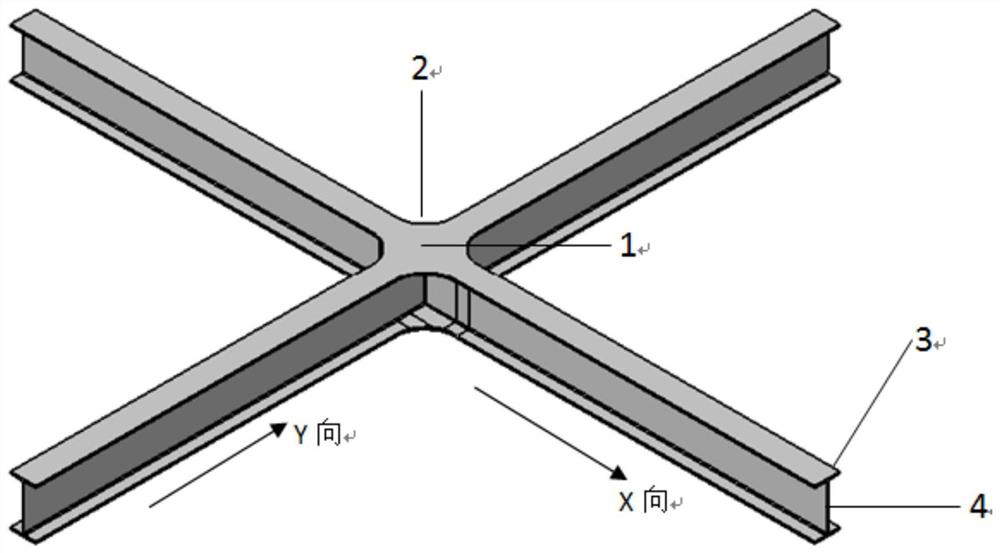

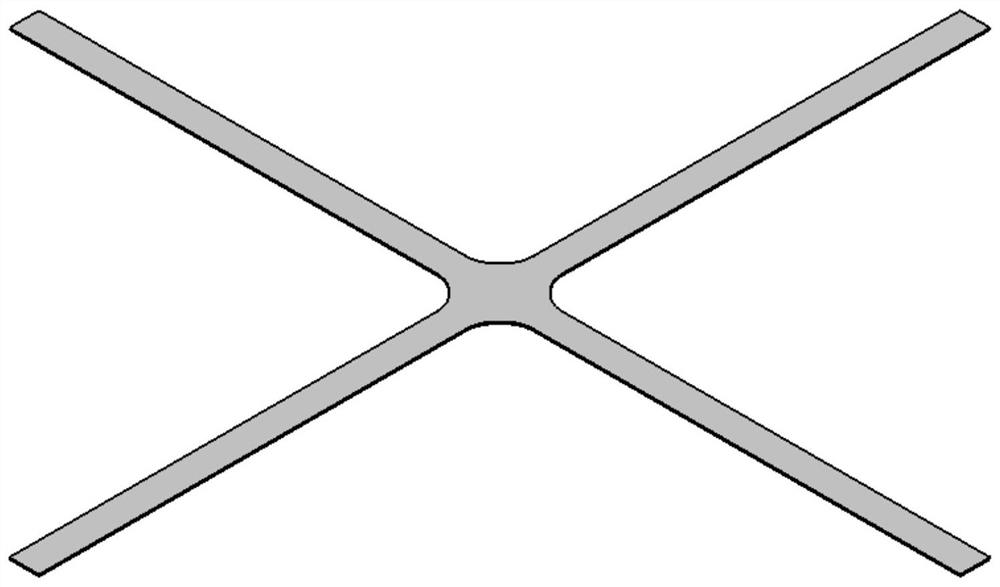

[0037]The embodiment of the present invention provides a composite material integrated frame beam, such asfigure 1 As shown, the integrated frame beam is a cross-shaped structure as a whole, one direction of the cross-shaped structure is the X direction, and the other direction is the Y direction;

[0038]The integrated frame beam description includes: upper cross pavement, middle cross pavement, and lower cross pavement;

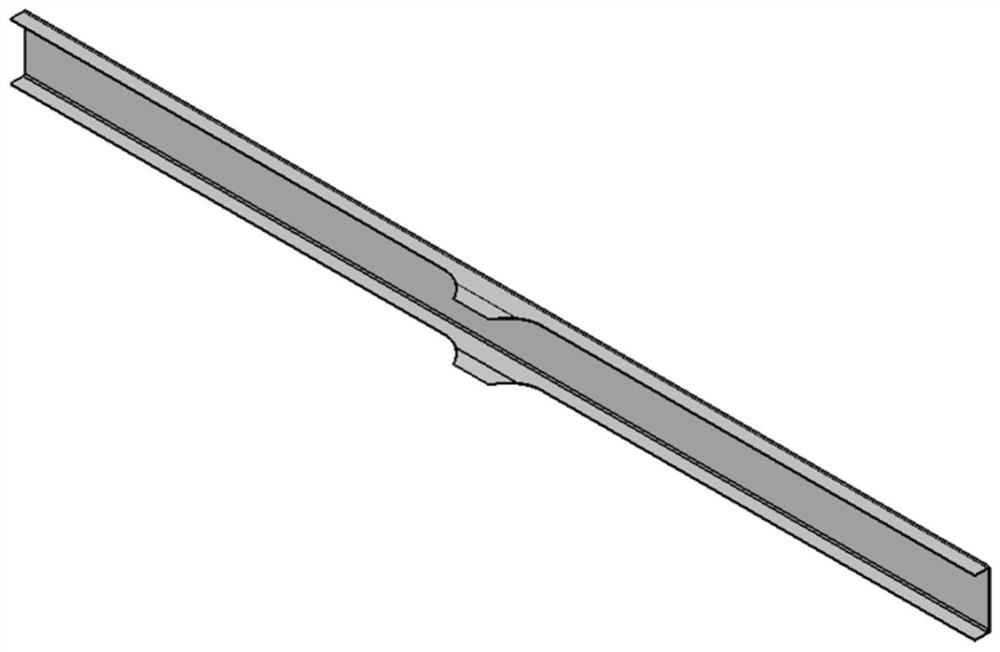

[0039]Among them, the middle cross-shaped ply includes an I-shaped cross-section in the X direction and an I-shaped cross-section in the Y direction; the I-shaped cross-section in the X direction includes two continuous composite fabrics with a C-shaped cross section, Y The layer with the I-shaped cross section is a discontinuous composite fabric, and includes the left half of the layer and the right half of the layer; both the left half of the layer and the right half of the layer are composed of two continuous layers of C-shaped cross-sections. Material fabric compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com