Injection molding process for flexible switch

An injection molding process and switch technology, which is applied to household components, household appliances, other household appliances, etc., can solve the problem of high production cost, and achieve the effects of beautiful and practical products, expanding the scope of application, and excellent induction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

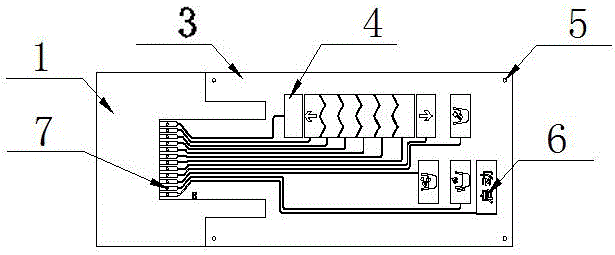

[0019] Such as Figure 1-4 As shown, a flexible switch injection molding process includes the following steps: Step 1: Place the printed PET film in a knife die for punching, and place the positioning holes at both ends of the sheet in a 2 mm diameter hole during punching. Punching on the positioning hole of the knife die;

[0020] Step 2: Put the toasted rice in the storage barrel, and the baking parameters for the rice to be baked are 80°C, 2H;

[0021] Step 3: Set the parameters of the injection molding machine, place the punched PET panel diaphragm into the cavity of the front mold, and the front of the sheet is in contact with the cavity of the front mold;

[0022] Step 4: Combine the ITO film diaphragm and the PET diaphragm through injection molding to complete the production.

[0023] In the step 4, put the row of pins into the cavity of the rear mold of the mold, and finally carry out the mold-closing injection molding production, so that after injection molding, one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com