Manufacturing technology for integrally prefabricating base of pump station

A manufacturing process and pumping station technology, which is applied to the manufacturing process field of the integrated prefabricated pumping station base, can solve problems such as affecting the use efficiency of the pump, being unable to pump sewage quickly, easily accumulating silt and water, and achieving adaptability Good, ensure integrity, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

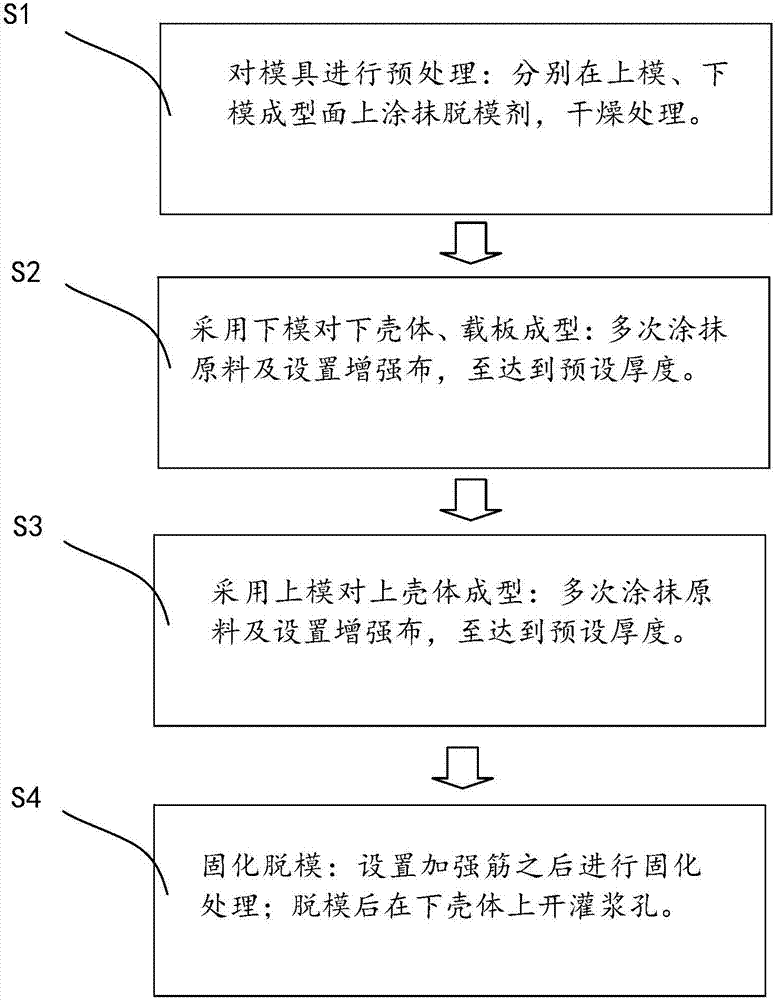

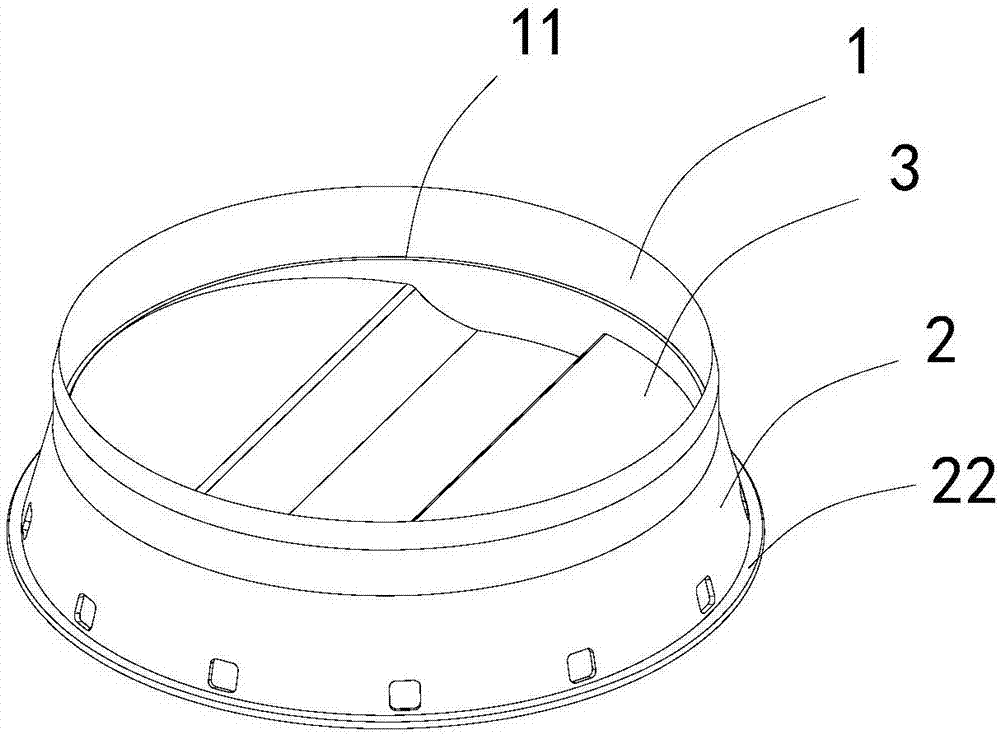

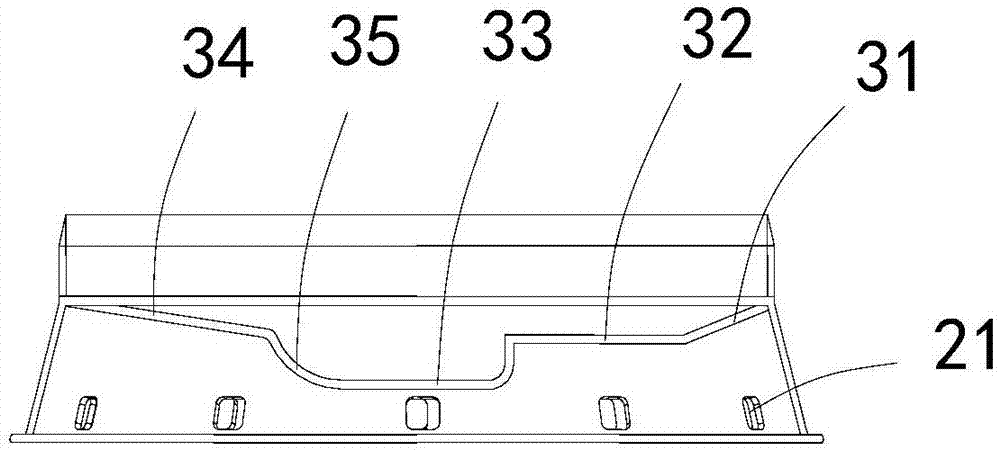

[0034] This embodiment provides a manufacturing process for an integrated prefabricated pump station base, such as figure 1 As shown, the base includes: an upper shell, a lower shell, and a carrier plate is arranged between the upper shell and the lower shell; the manufacturing process includes the following steps:

[0035] S1. Pretreat the mold: the mold includes a lower mold and an upper mold, the lower mold is used to form the lower shell and the carrier plate, and the upper mold is used to form the upper shell; apply demoulding on the molding surface of the upper mold and the lower mold agent, and carry out sufficient drying treatment.

[0036] S2. Use the lower mold to form the lower shell and the carrier plate: evenly paint the raw material on the molding surface of the lower mold, and lay a reinforcing cloth on the surface of the lower mold after brushing the raw material, and discharge the air bubbles in the reinforcing cloth and the raw material ; After a period of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com