Preparation method of cubing

A technology for inspection tools and car bodies, applied in the field of preparation of main inspection tools for car bodies, can solve the problems that the manufacturing process cannot adopt an integrated molding process, reduce the detection accuracy, and have a long production cycle, so as to shorten the production cycle, save raw and auxiliary materials, Product quality light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation of the present invention will be described in detail below in conjunction with examples. It should be understood that the examples are provided to illustrate the invention and not to limit the invention. The scope and essential content of the present invention are defined by the claims.

[0020] The preparation method of the vehicle body main inspection tool of the present invention:

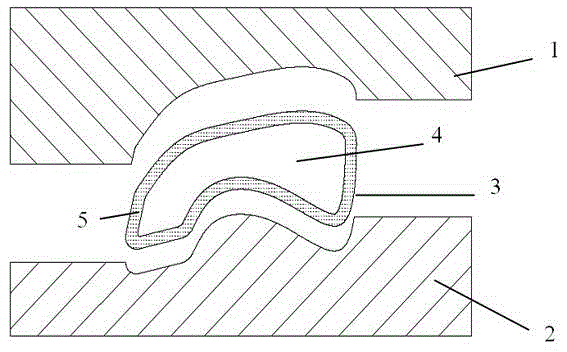

[0021] 1. Mold design and processing: According to the shape and size of the product, polymer fiber is selected as the mold material, and then the mold is processed by CNC, which is divided into upper mold 1 and lower mold 2. The upper mold and the lower mold are equipped with a glue injection port and an exhaust glue outlet. The glue injection pipe and the glue injection port are designed to inject glue along the longest side of the grid, and at the same time, the exhaust glue outlet is designed on the opposite side of the glue injection port. .

[0022] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com