Stripline-style ferrite phase shifter based on LTCC technology

A ferrite and phase shifter technology, applied in waveguide devices, electrical components, circuits, etc., can solve the difficulty of miniaturization, the complex structure of ferrite phase shifters, and the lack of miniaturized LTCC stacked structure ferrite Volume phase shifter and other issues to achieve the effect of volume and quality reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below with reference to a specific implementation and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0026] The specific implementation of the LTCC laminated stripline ferrite phase shifter has a center frequency of about 9.2GHz, a bandwidth of more than 300MHz, an insertion loss within the bandwidth of <2dB, a standing wave ratio of VSWR≤1.5, and a phase shift of more than 270 degrees. The length, width and height of the ferrite phase shifter are only about 20mm, 10mm and 4mm, which are much smaller than conventional waveguide type and microstrip type ferrite phase shifters.

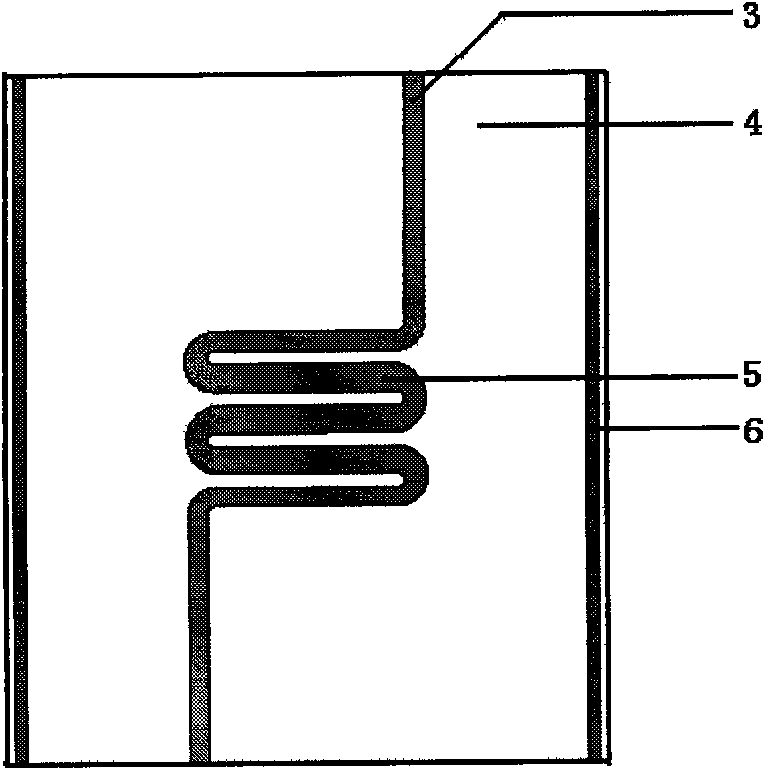

[0027] Figure 1 ~ Figure 4 It is a schematic diagram of each layer and the whole structure of the LTCC laminated stripline ferrite phase shifter. The main structures include:

[0028] The lower ferrite substrate is formed by stacking 15 sheets of low-temperature sintered gyromagnetic l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com