Microwave ferrite material with gradient saturation magnetization intensities, ferrite substrate prepared from microwave ferrite material and preparation method of ferrite substrate

A ferrite material and magnetization technology, applied in the field of microwave technology and magnetic materials, can solve problems such as inability to combine together, crystal structure, and large differences in sintering shrinkage at solid-phase reaction temperature, so as to expand device bandwidth and achieve Miniaturization and integration, the effect of reducing the size of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

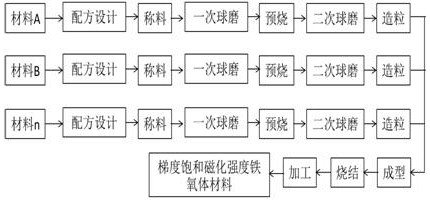

[0036] A preparation method of gradient saturation magnetization microwave ferrite substrate, such as figure 1 shown, including the following steps:

[0037] (1) Formula design, according to the compositional chemical formula Bi h Gd k Y 3-h-k-(a+c+2d+f) Ca a+c+2d+ f Sn a In b Zr c V d Al e Ge f Fe 5-a-b-c-d-e-f-δ1 O 12 Carry out the formula design of material A1, wherein a=0.25, b=0, c=0.15, d=0.5, e=0.28, f=0.12, h=0, k=0.1, δ1=0.02; according to the chemical formula Bi h Gd k Y 3-h-k-(a+c+2d+f) Ca a+c+2d+f Sn a In b Zr c V d Al e Ge f Fe 5-a-b-c-d-e-f-δ1 O 12 Carry out the formula design of material B2, where a=0.15, b=0.2, c=0, d=0, e=0, f=0, h=0.2, k=0, δ1=0.02;

[0038] (2) weighing materials, according to the formula design results of material A1 and material B2 in step (1), calculate and weigh various required raw materials respectively, and the raw materials are Y 2 O 3 , Fe 2 O 3 , Bi 2 O 3 , Gd 2 O 3 , CaCO 3 , V 2 O 5 , ZrO 2 , S...

Embodiment 2

[0050] A preparation method of a gradient saturation magnetization microwave ferrite substrate, comprising the following steps:

[0051] (1) Formula design, according to the compositional chemical formula Ni 1-x+y-z Zn x Dy n Sn y Co z Mn m Fe 2-2y-m-n-δ2 O 4 Carry out the formula design of material A1, where x=0.2, y=0.1, z=0.01, m=0.08, n=0.02, δ2=0.1; according to the compositional chemical formula Ni 1-x+y-z Zn x Dy n Sn y Co z Mn m Fe 2-2y-m-n-δ2 O 4 Carry out the formula design of material B2, where x=0.45, y=0, z=0.02, m=0.04, n=0.05, δ2=0.1;

[0052] (2) weighing material, according to the formula design results of material A1 and material B2 in step (1), calculate and weigh various required raw materials respectively, and the raw material is Fe 2 O 3 , SnO 2 , NiO, ZnO, Dy 2 O 3 , Co 2 O 3 , MnCO 3 ;

[0053] (3) One-time wet ball milling of raw materials, mix various raw materials of material A1 weighed in step (2) and put them into ball mill j...

Embodiment 3

[0064] A preparation method of a gradient saturation magnetization microwave ferrite substrate, comprising the following steps:

[0065](1) Formula design, according to the compositional chemical formula Bi h Gd k Y 3-h-k-(a+c+2d+f) Ca a+c+2d+ f Sn a In b Zr c V d Al e Ge f Fe 5-a-b-c-d-e-f-δ1 O 12 Carry out the formula design of material A1, where a=0.2, b=0.2, c=0, d=0.4, e=0.25, f=0, h=0, k=0.07, δ1=0.08;

[0066] According to the compositional formula Ni 1-x+y-z Zn x Dy n Sn y Co z Mn m Fe 2-2y-m-n-δ2 O 4 Carry out the formula design of material B2, where x=0.1, y=0.12, z=0, m=0.1, n=0.05, δ2=0.08; according to the compositional chemical formula Ni 1-x+y- z Zn x Sn y Co z Mn m Fe 2-2y-m-n-δ2 O 4 Carry out the formula design of material C3, where x=0.2, y=0.02, z=0.05, m=0.05, n=0.2, δ2=0.05;

[0067] (2) Weighing, according to the formula design results of material A1, material B2, and material C3 in step (1), calculate and weigh the required va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com