Microstrip line phase shifter based on LTCC technology

A technology of microstrip line and phase shifter, which is applied to waveguide-type devices, electrical components, circuits, etc., can solve the problems of large size, inability to miniaturize, and difficult to miniaturize the magnetizing circuit, and achieves overcoming process sensitivity and realizing miniaturization. effect of reduction, volume and mass reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

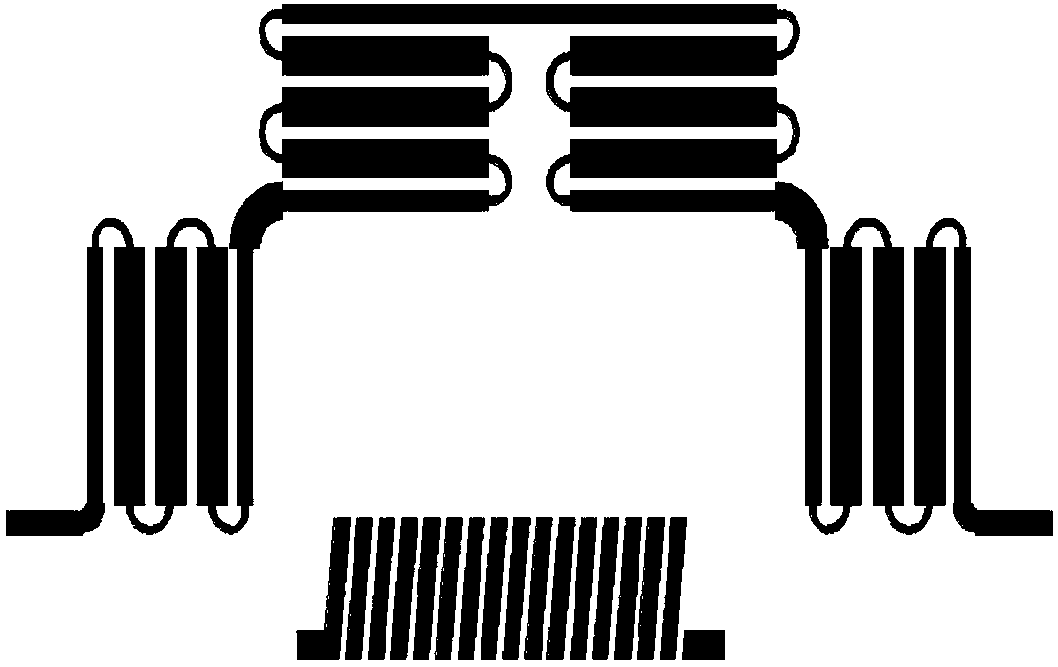

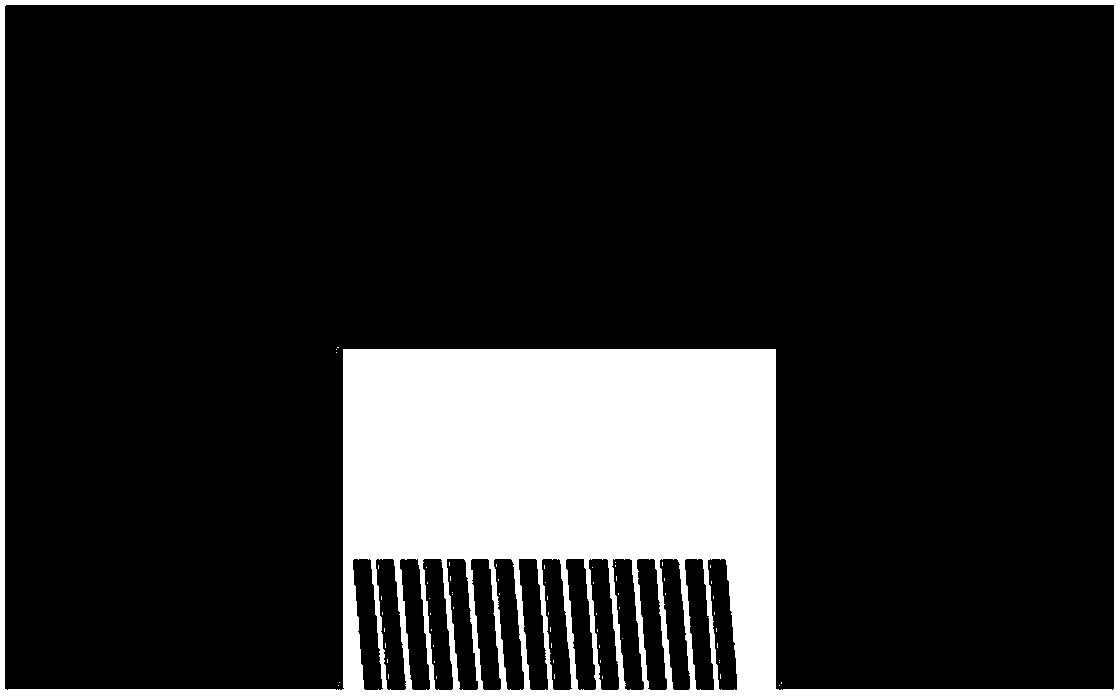

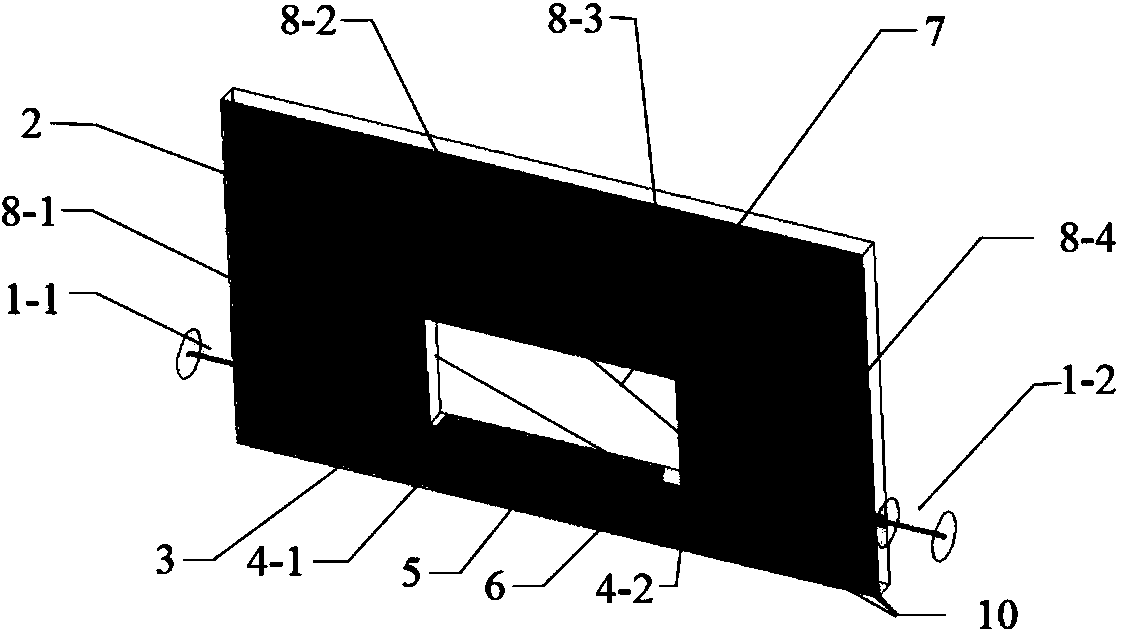

[0029] The phase shift excellent value parameter and reflection parameter of the present invention are mainly determined by the intrinsic parameters of the ferrite substrate material, the thickness of the ferrite substrate, and the length of the curved coupling microstrip line. The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings, but the present invention is not limited thereto.

[0030] The simulation results of the microstrip line phase shifter based on LTCC technology are as follows: Figure 6 to Figure 8 As shown, the center frequency is 11.5GHz, the bandwidth is 3.5GHz, the insertion loss within the bandwidth is <1.1dB, and the phase shift figure of merit is 290° / dB. The physical size of the phase shifter is: length*width*height=28mm*16mm*1.01mm, which is smaller than the conventional waveguide type phase shifter and close to the physical size of the microstrip ferrite phase shifter.

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com