Coating and optical element

A coating and mixture technology, applied in optical components, coatings, optics, etc., can solve the problems of poor adhesion between coatings and substrates, low wear resistance and hardness, achieve high adhesion, increase toughness, prevent warping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

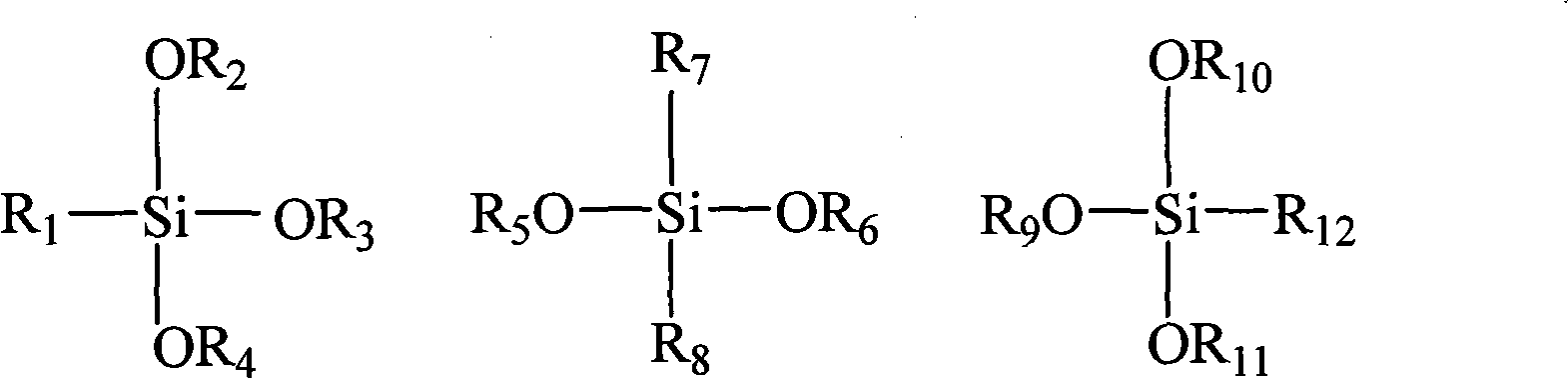

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the optical element provided by the present invention can adopt various coating methods commonly used in the prior art to form a coating on a transparent substrate, for example, the coating composition can be coated on a transparent substrate by various common methods surface, and then cured to obtain the coating of the present invention on the surface of the transparent substrate, thereby preparing the optical element of the present invention. In order to ensure that the coating forms a suitable thickness on the surface of the transparent substrate, the amount of the coating composition is 0.05-0.5g / cm 2 .

[0037] In order to improve the adhesion between the coating and the transparent substrate, before the surface of the transparent substrate is coated with the coating composition, the transparent substrate can also be roughened with chromic anhydride to roughen the surface of the transparent substrate, thereby improving the adhesion between...

Embodiment 1

[0040] 1) Put the 70×40×1.5mm PC board into the chromic anhydride roughening solution, soak for 10 minutes at 60°C; transfer to 10wt% oxalic acid solution, soak for 5min at 60°C; transfer to 10wt% sodium hydroxide solution Soak in water for 30s, rinse with clean water and dry. Chromic anhydride roughening liquid: 160ml pure water, 130ml concentrated sulfuric acid, 28g potassium dichromate.

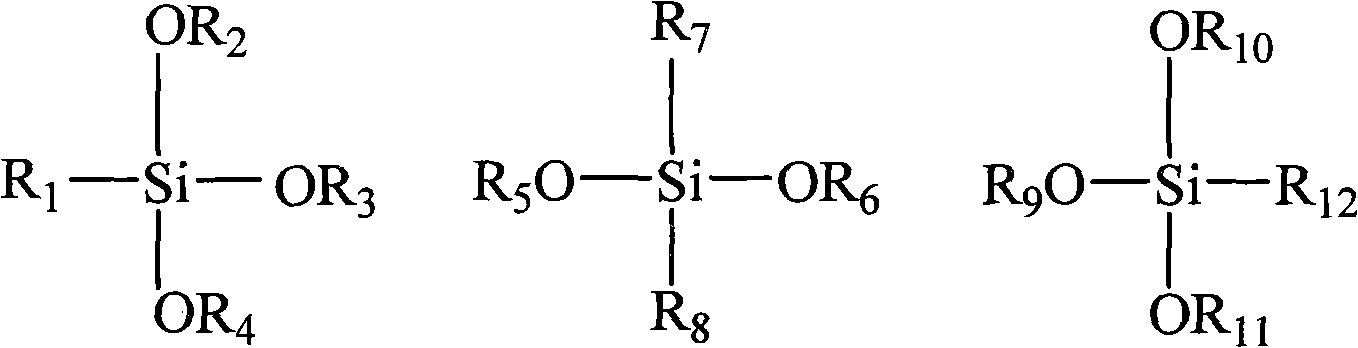

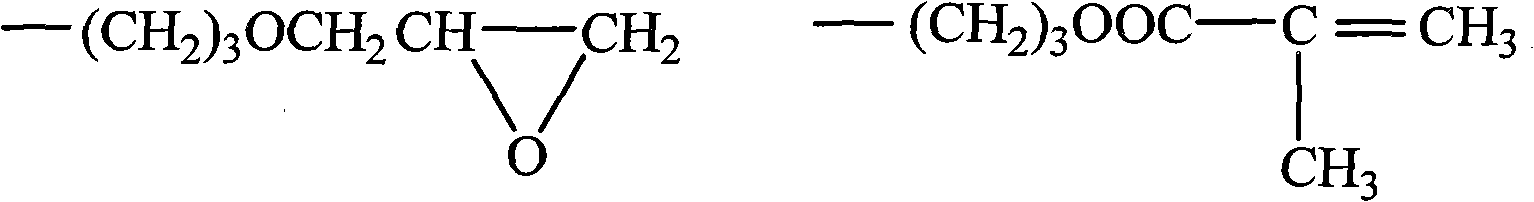

[0041] 2) Take 18g of methyltriethoxysilane, 2g of dimethyldiethoxysilane, 19g of deionized water, 1.5g of itaconic acid and 8.4g of isopropanol, stir and hydrolyze for 2 hours; add dropwise 30g of KH560 and 14.5 g deionized water mixture, react at 40°C for 2h; add 18g of silica sol (Sunardi acidic silica sol, average particle size 15nm), 0.4g of N,N-dimethylbenzylamine, 0.4g of FC-430 and mix for 12h , to obtain a coating composition.

[0042] 3) Apply the coating composition prepared in the brushing step 2) to one side of the transparent substrate after step 1), and the amount of brush...

Embodiment 2

[0044] Adopt the same method as embodiment 1 to prepare the optical element, the difference is that,

[0045] In step 2), take 19g methyltriethoxysilane, 1g dimethyldiethoxysilane, 21g deionized water, 1.5g itaconic acid and 15g isopropanol, stir and hydrolyze for 2h; add dropwise 40g KH560 Mix with 17.5g of deionized water, react at 40°C for 2h; add 25g of Shanghai Hengsheng Chemical Co. 12h.

[0046] Through the above steps, the optical element of this embodiment is obtained, which is denoted as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com