Helical electromagnetic stirring device

A technology of spiral electromagnetic stirring and electromagnetic induction, which is applied in the field of electromagnetic casting and electromagnetic processing of materials, can solve the problems of limited spiral stirring effect and unfavorable spiral stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

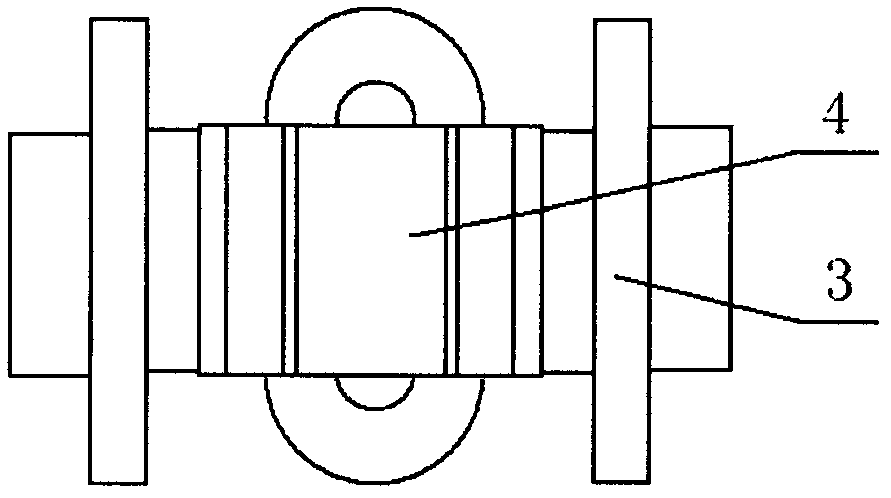

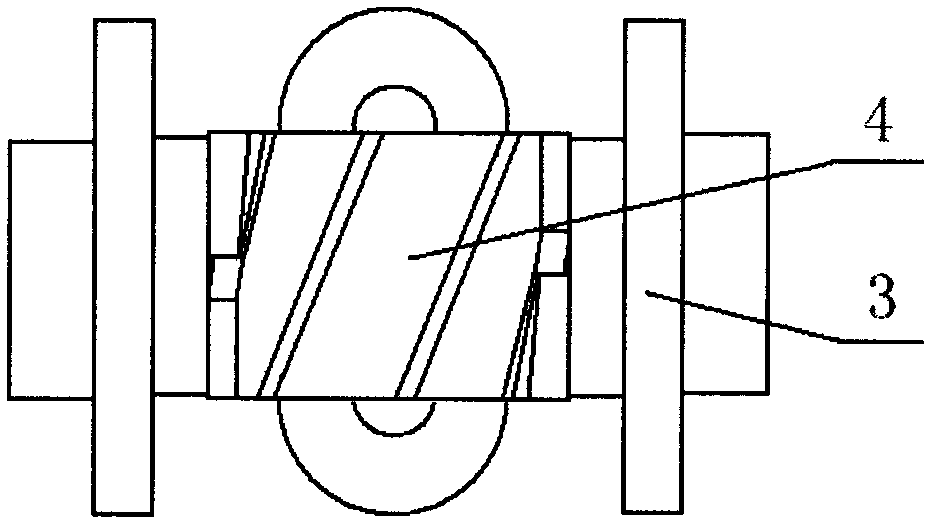

[0023] Embodiment 1: as image 3 and 4 As shown, it is suitable for the spiral electromagnetic stirring device where the billet is round billet or square billet.

[0024] 1. Electromagnetic induction system

[0025] It consists of a set of coil windings 3 and a magnetic yoke set made of silicon steel. The coil 3 is made of a hollow copper wire, and the inside can be cooled by cooling water. After the coil is insulated, it is placed on the yoke, and the yoke is supported and fixed in the box body 5 by the lower block 6 and the upper block 2 . The magnitude of the current passed through the coil 3 is an important factor affecting the stirring effect, and the current should be adjustable within the range of 0 to the rated current according to needs. The inclined yoke end face 4 is the key of the present invention. Each yoke end face 4 is inclined relative to the yoke back 12, and is inclined 30° relative to the vertical direction. The height of the yoke group is 80mm, and eac...

Embodiment 2

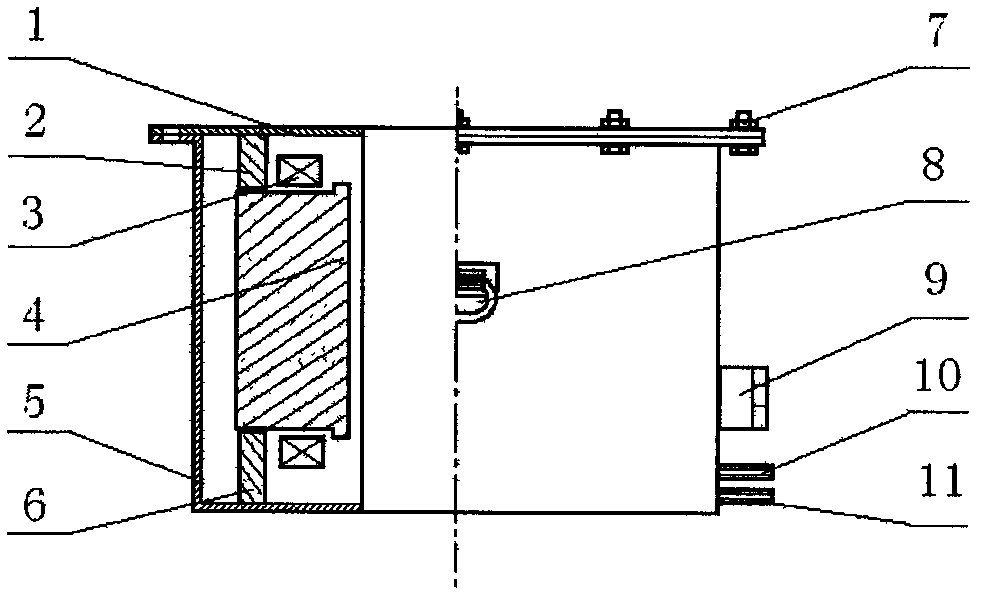

[0033] Embodiment 2: as Figure 5 and 6 As shown, it is suitable for the spiral electromagnetic stirring device where the cast slab is a slab.

[0034] 1. Electromagnetic induction system

[0035] It consists of a set of yokes with high saturation magnetic induction and high permeability and coils 3 wound on the yokes. Such as Figure 5 and Figure 6As shown, the yoke set is composed of a yoke back 12 and several yoke end faces 4, which are arranged in a straight line. The end face 4 of the yoke is inclined relative to the back 12 of the yoke, and the included angle with respect to the vertical direction is 25°. The height of the yoke group is 200 mm, and the gap between the end faces 4 of the yoke is 20 mm. A total of seven yoke end faces 4 are arranged in a straight line, and more yoke end faces 4 may form a linear shape similar to a traveling wave magnetic field stirrer for spiral stirring of slabs and long and narrow areas. The yoke group is fixed in the box body 5 b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com