Electromagnetic device for stirring metal melt spirally

A technology of spiral electromagnetic stirring and metal melt, which is applied in the fields of electromagnetic casting and electromagnetic processing of materials, can solve the problems of limited spiral stirring effect and unfavorable spiral stirring, and achieves reduction of thermal cracking and macrosegregation, reduction of component segregation, elimination of The effect of shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

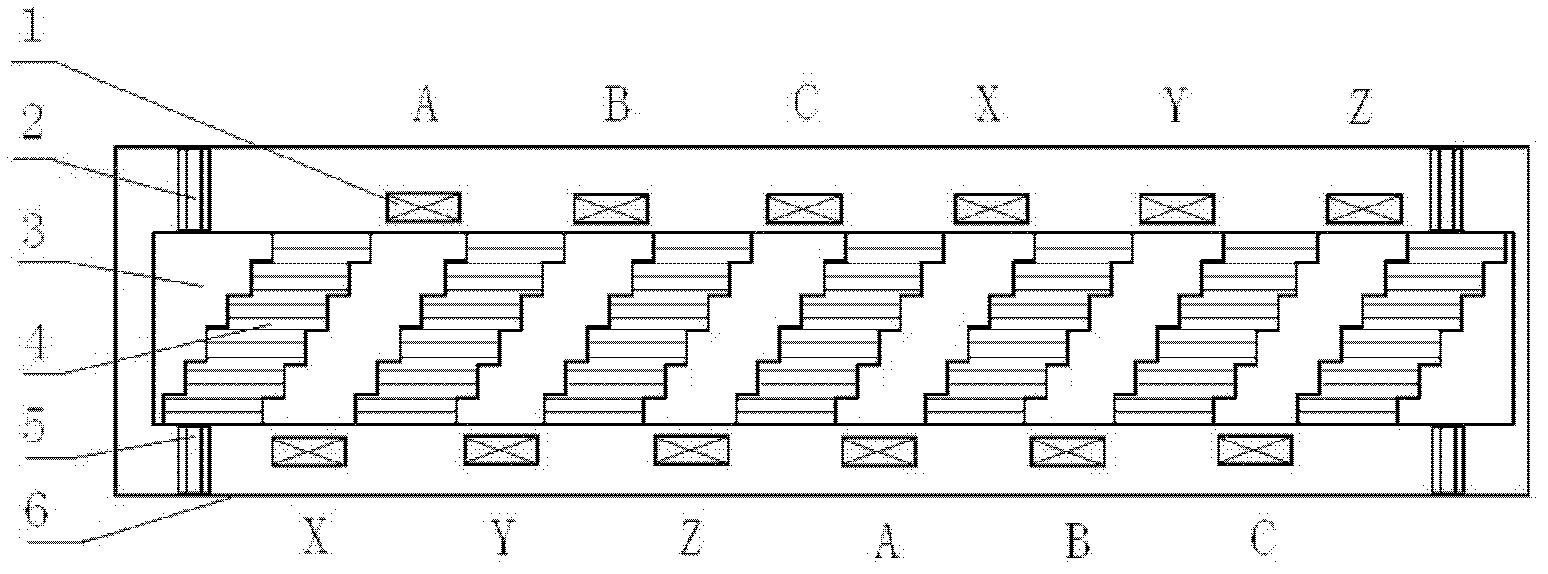

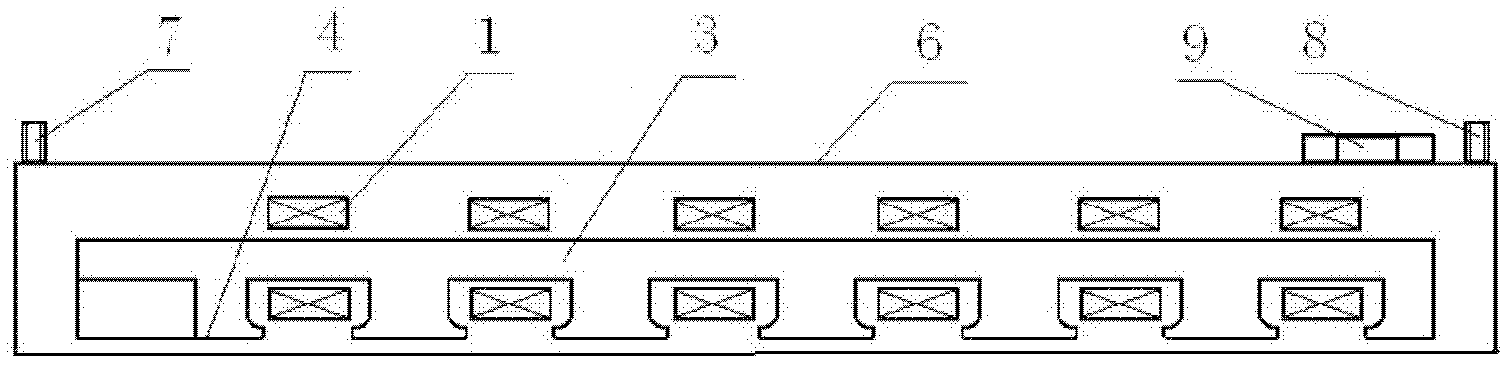

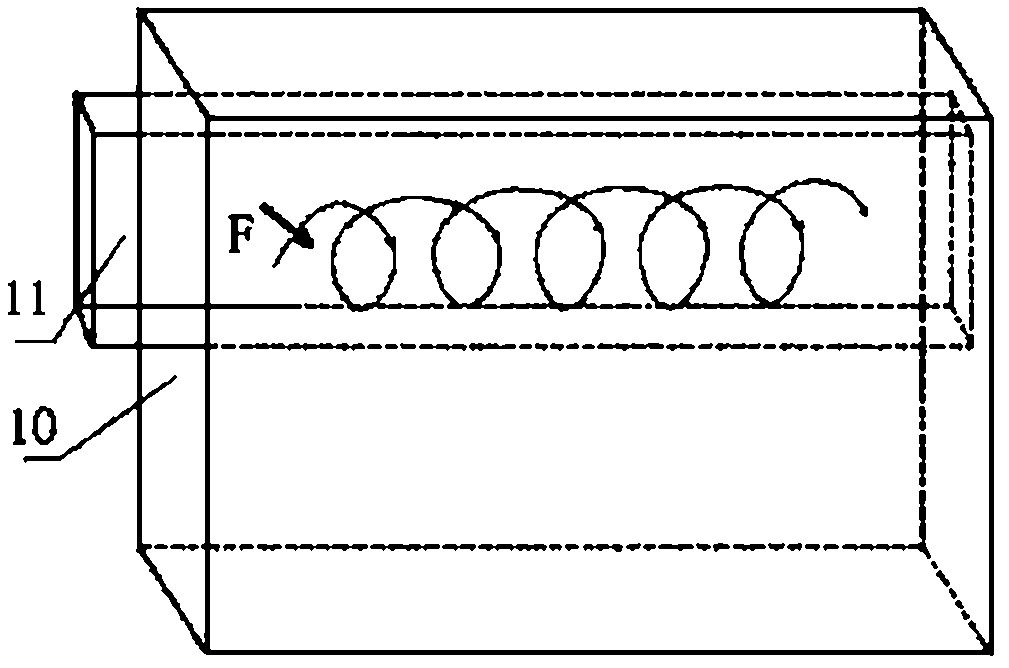

[0025] Such as figure 1 , figure 2 , Figure 6As shown, the electromagnetic induction system is composed of a yoke set and a coil 1 set on the yoke set. The yoke set is composed of a yoke back 3 and 1 to 8 sets of yoke ends 4 connected to the yoke back. The yoke The side of the end portion 4 presents a stepped structure, capable of generating electromagnetic forces in vertical and horizontal directions. The height of the yoke in the electromagnetic induction system is 10~5000mm. The gap between the ends of the yoke is 2~200mm. The transition between the yoke and the end of the yoke is in a circular arc, which is conducive to magnetic conduction. The yoke group is fixed in the box 6 by means of an upper block 2 and a lower block 5 made of insulating material. The coil is wound with copper wire or hollow copper tube. The coil 1 is wound in the gap between the yokes in the Gramm winding, overlapping winding and concentrated winding arrangements. The coil of the electroma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com