Heavy reduction sector section used for overcoming plate blank looseness and shrinkage defects and application method thereof

A sector section and heavy reduction technology, which is applied in the field of sector section under heavy pressure, can solve the problems such as not being able to meet the reduction amount, and achieve the effect of less porosity and shrinkage cavity defects, and high quality of cast slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

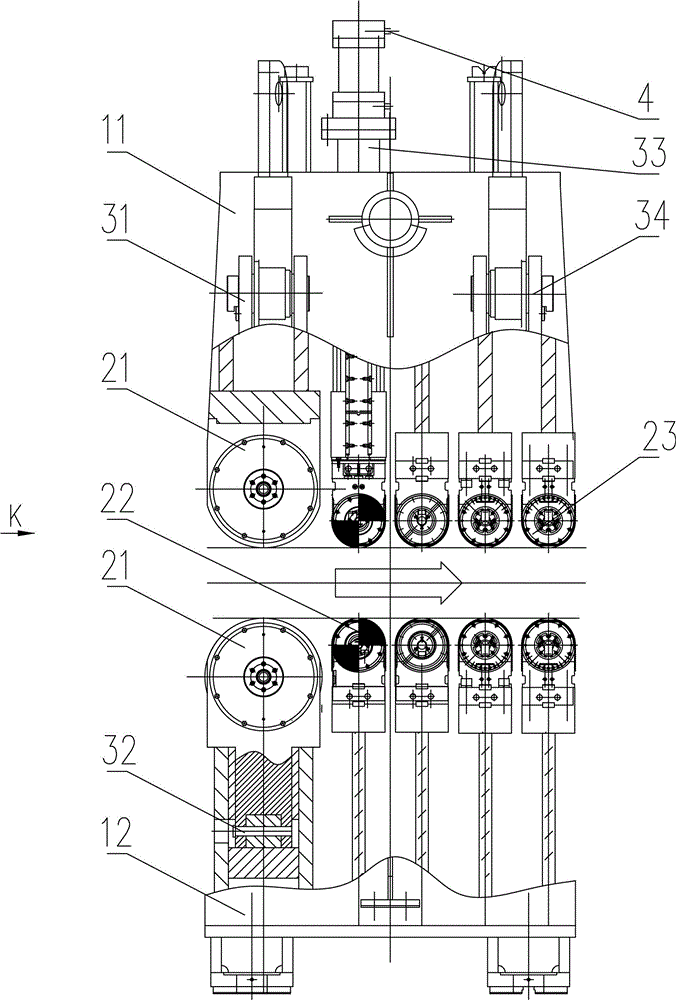

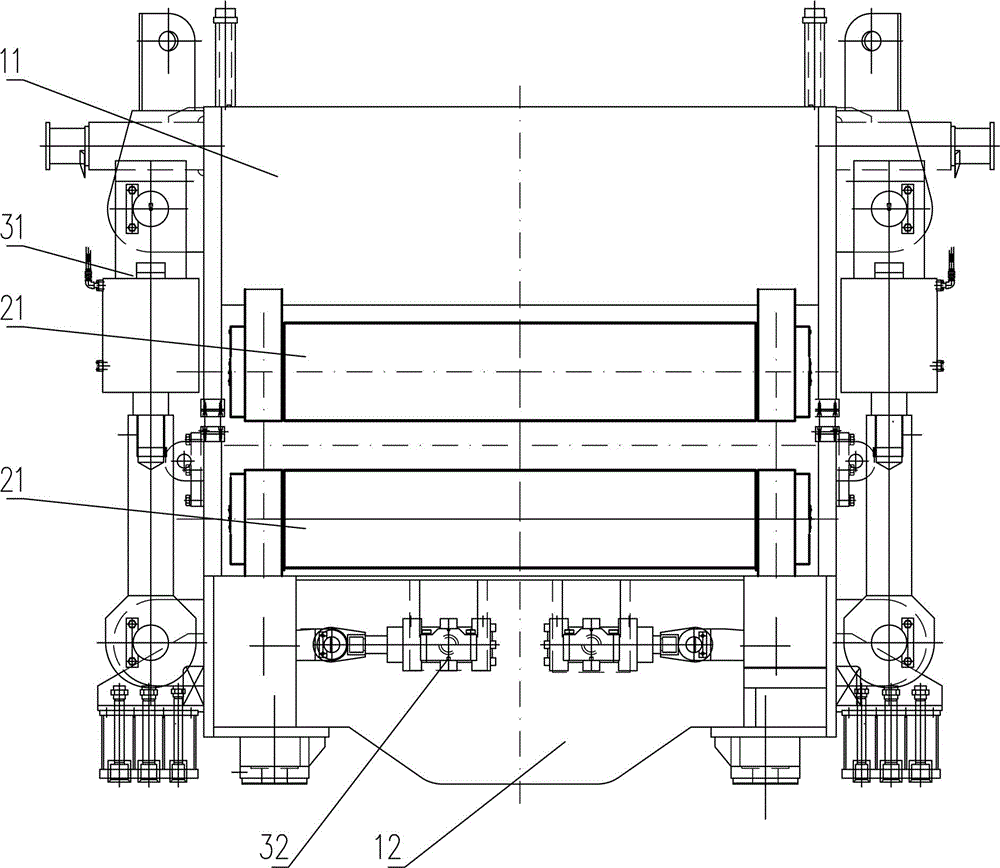

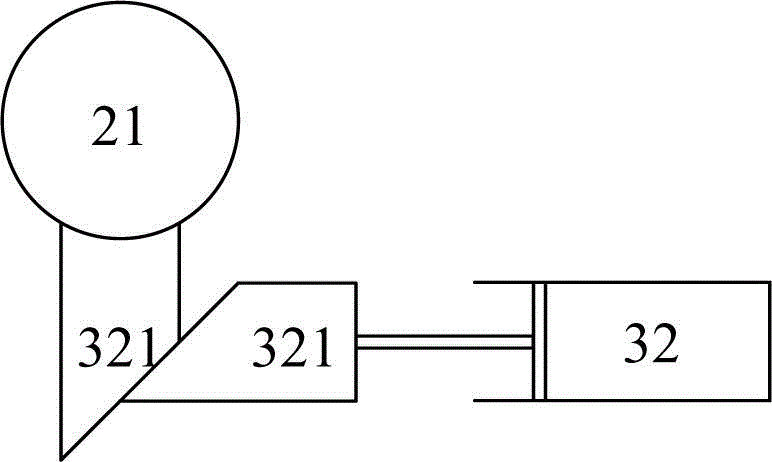

[0027] A heavy-pressed lower fan section for improving loose shrinkage defects of slabs, including an upper frame 11, a lower frame 12, a pair of large free rollers 21, a pair of driving rollers 22, three pairs of small free rollers 23, and a large free roller Depress oil cylinder 31, horizontal oil cylinder 32, drive roller press down oil cylinder 33 and water pipe 4, as figure 1 and figure 2 As shown, the specific structure is:

[0028] The upper frame 11 is located directly above the lower frame 12, and the upper frame 11 and the lower frame 12 are hinged together by two pairs of clamping hydraulic cylinders through connecting shafts and joint bearings; both the upper frame 11 and the lower frame 12 adopt a vertical plate structure , with high strength and rigidity, which meets the requirements of roll gap control and adjustment under heavy pressure. The vertical plate structure has good permeability and strong thermal deformation resistance, which is conducive to the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com