Circular tubular heat pipe having a sealed structure closing a distal opening thereof

a tubular heat pipe and sealed technology, applied in the direction of indirect heat exchangers, light and heating apparatus, etc., can solve the problems of cpu even stopping working, wasting time, increasing cost, etc., to facilitate pretreatment of heat pipes, shorten welding time, and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

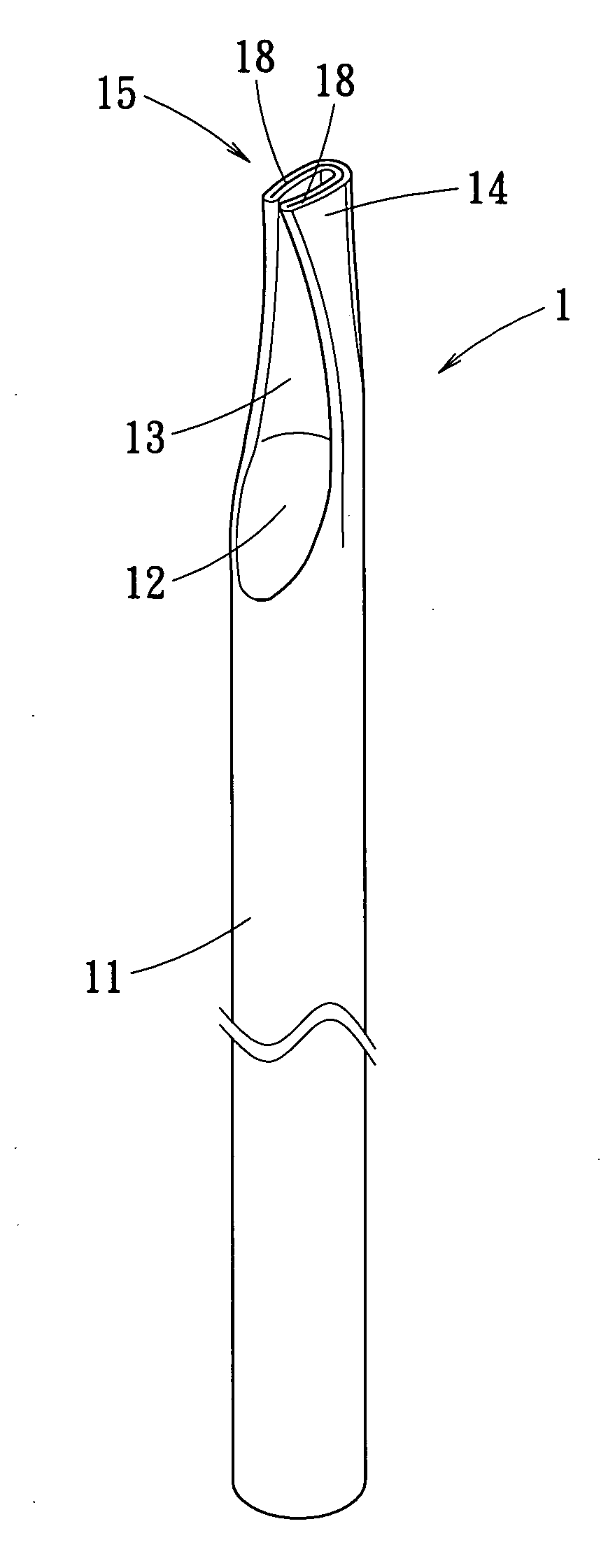

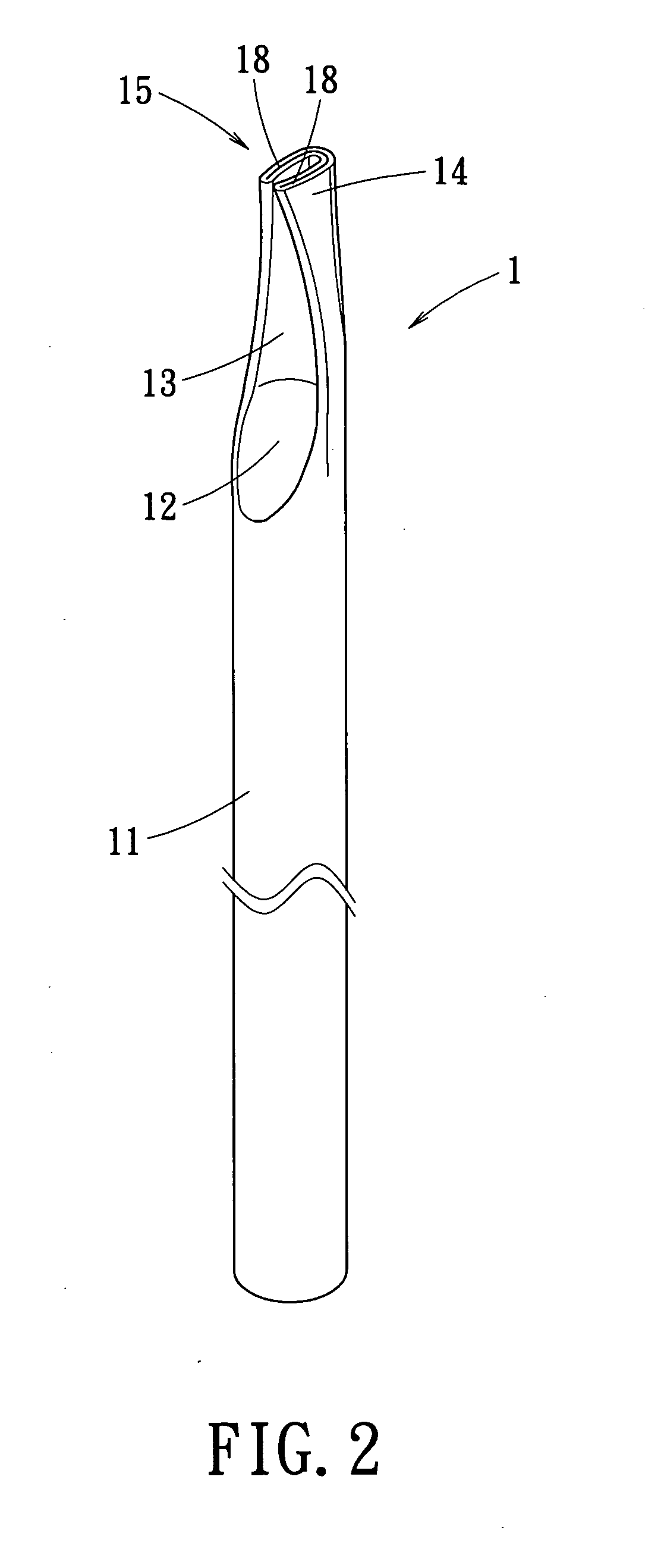

[0032] Referring to FIG. 2, a circular tubular heat pipe having a sealed structure closing a distal opening 15 thereof in accordance with the present invention is shown. A method for fabricating the sealed structure comprises:

[0033] Step 1: pressing a region of the heat pipe adjacent to the distal opening 15 to pinch a circular tubular pipe formed an overlapping wall thereof.

[0034] Referring to FIG. 3 and FIG. 4, placing the distal opening 15 of the heat pipe to a press mold set including an upper mold 16 and a lower mold 17. A region of the heat pipe adjacent to the distal opening 15 is pressed to form a concave wall portion 12 as shown in FIG. 5. A pressed recess portion 13 is formed on the concave wall portion 12 adjacent to the distal opening 15. The heat pipe is formed to have a overlapping wall at the pressed recess portion 13. A pair of wing portions 18 is formed on the pressed recess portion 13 adjacent to the distal opening 15. The pressed recess portion 13 can be further...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com