Numerical control rotating three-dimensional ultrasonic gold wire bonder

A gold wire ball welding and ultrasonic technology, which is applied to welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of large human resources consumption, low efficiency, and long welding time, so as to shorten the welding time and save human resources , The effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

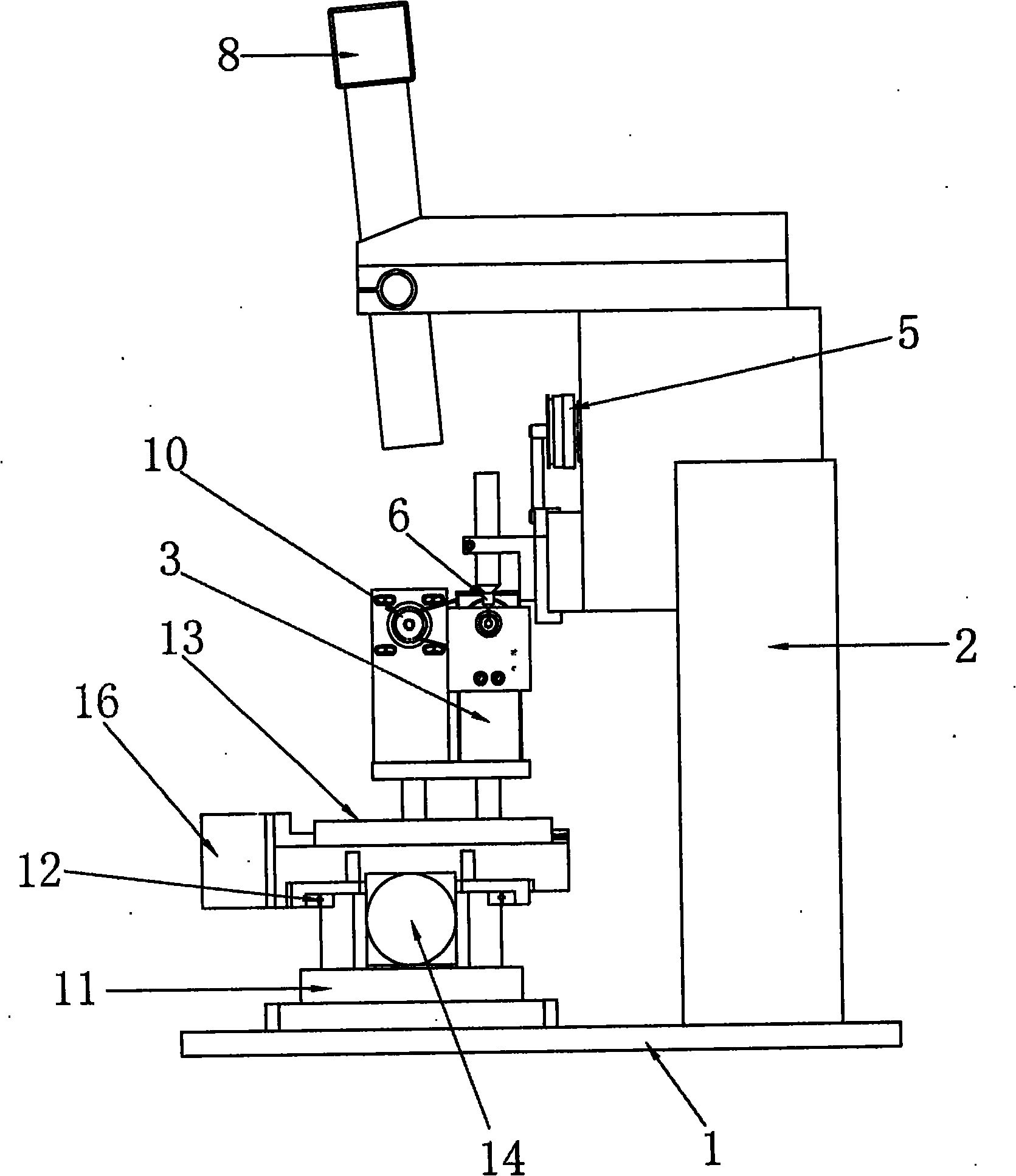

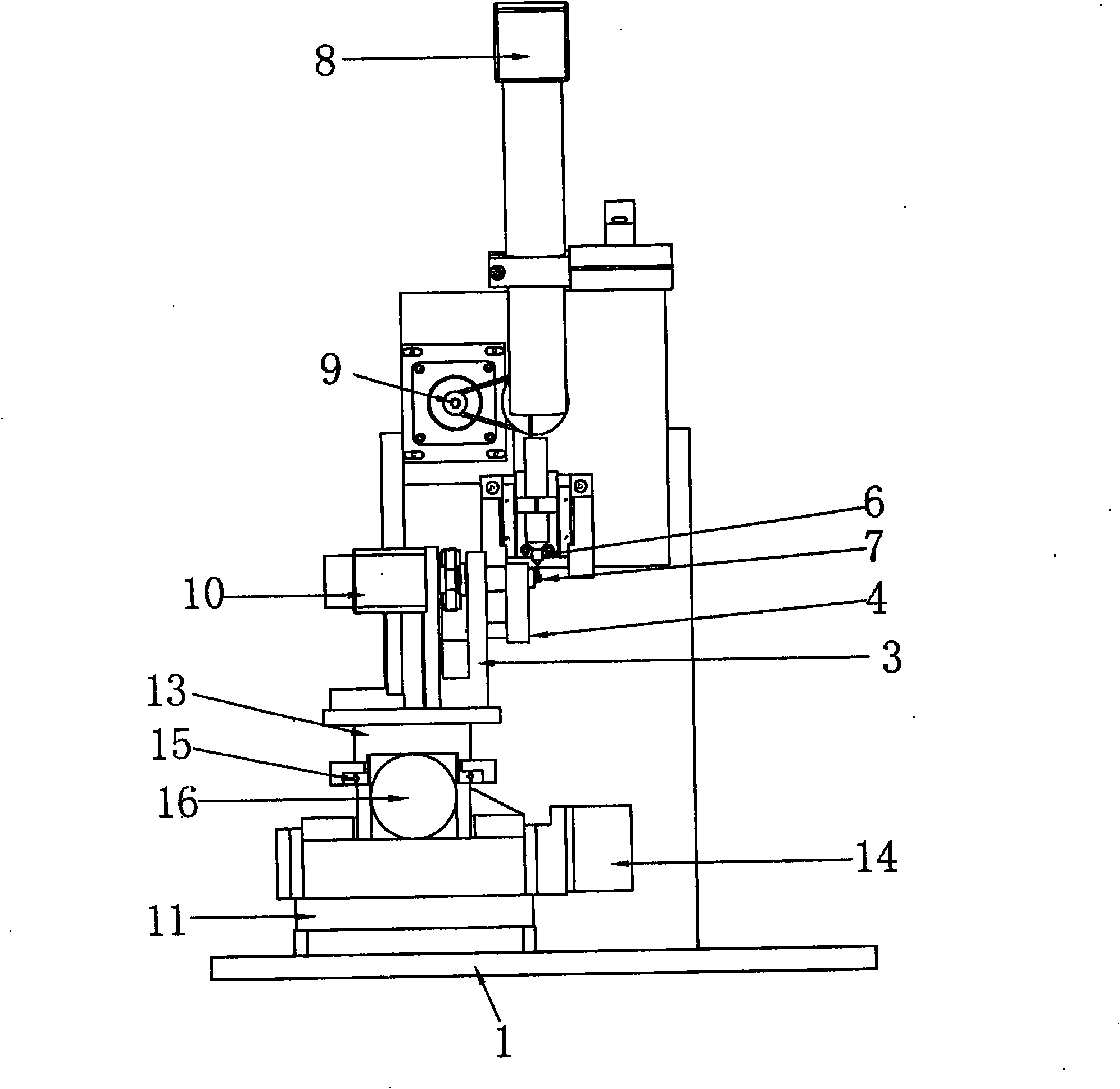

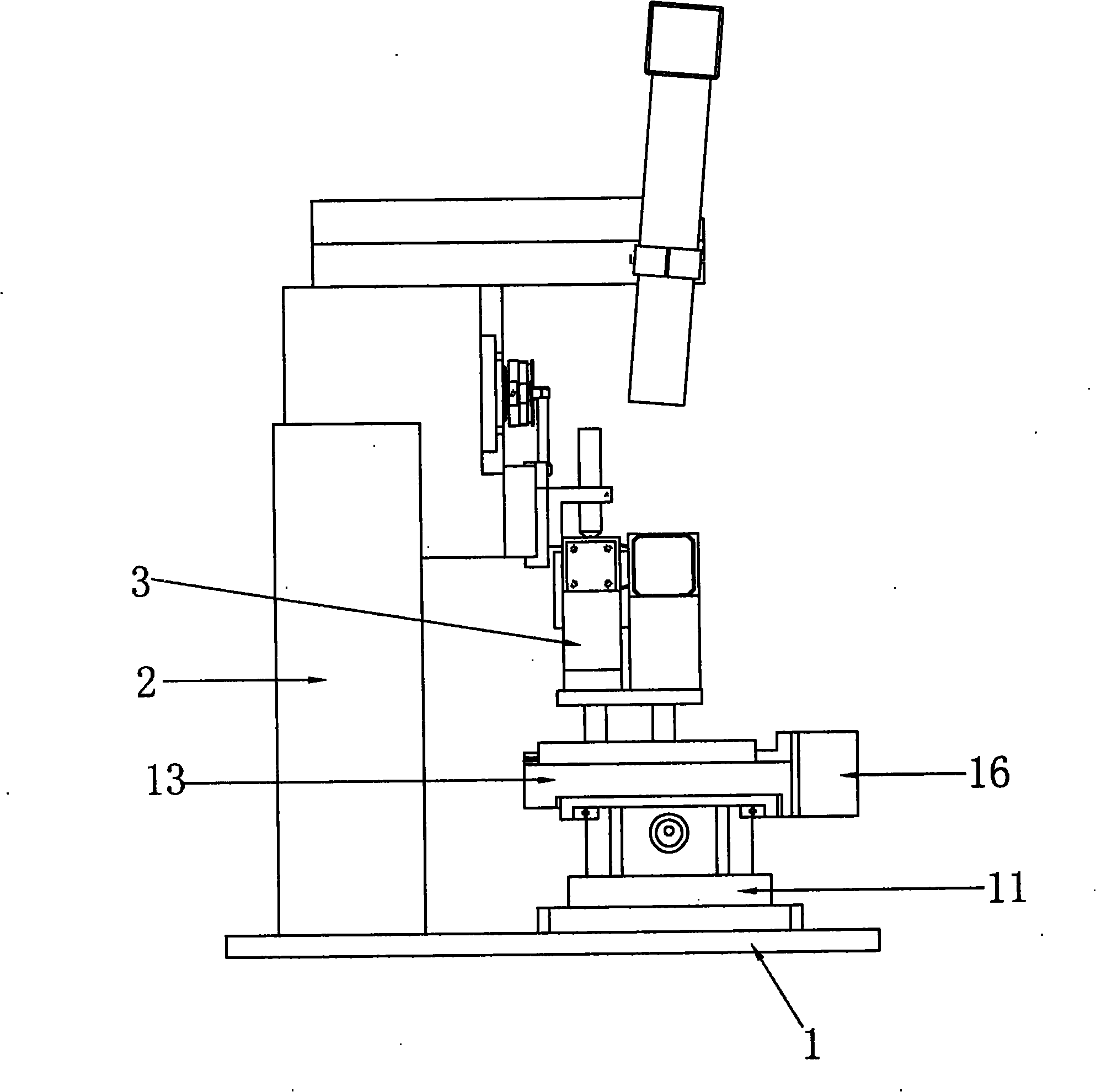

[0013] refer to figure 1 , figure 2 , image 3 , the numerically controlled rotary three-dimensional ultrasonic gold wire ball welding machine disclosed by the present invention comprises a base plate 1, a machine base 2 and a numerical control system (not shown in the figure), and an X, Y axis moving platform is installed on the base plate 1, and X, Y A device fixture seat 3 is installed on the axis moving platform, a heating block 4 is installed on the device fixture seat 3, a Z-axis workbench 5 is installed on the machine base 2, and the Z-axis workbench 5 can move up and down through a Z-axis motor 9. Z-axis motor 9 can adopt stepping motor or servo motor, and spot welding head 6 is installed on the Z-axis workbench 5, and device fixture 7 is installed on device fixture seat 3 and heating block 4, and the spot welding head 6 and device fixture 7 Corresponding to the position, the base 2 is equipped with a camera 8 that can photograph the device on the device fixture 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com